Radial magnetic bearing of low-power consumption inner rotor of permanent-magnetic up-attracting and down-repelling structure

A low-power, inner-rotor technology, used in bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of high current consumption, difficult installation, complex control, etc., to reduce iron loss, low loss, and eliminate magnetic loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

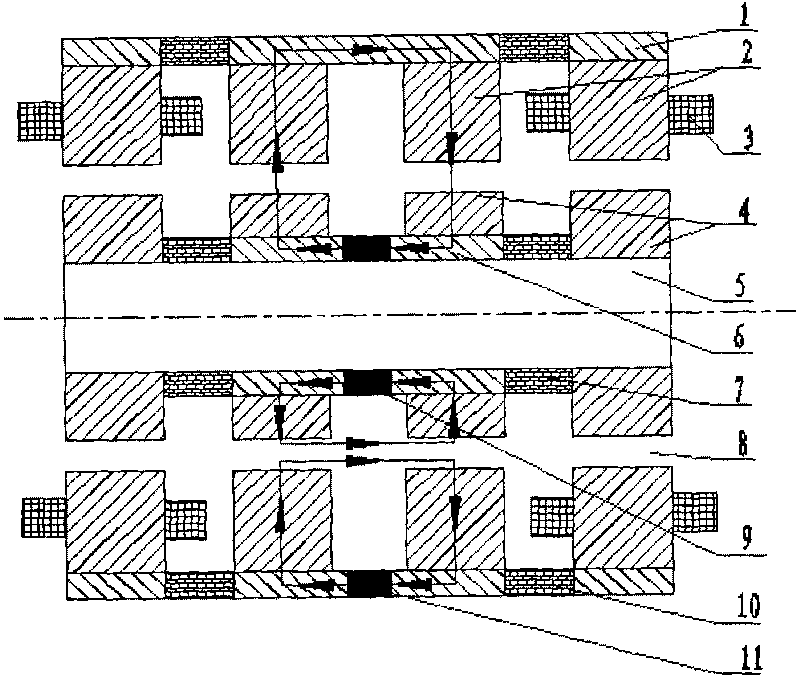

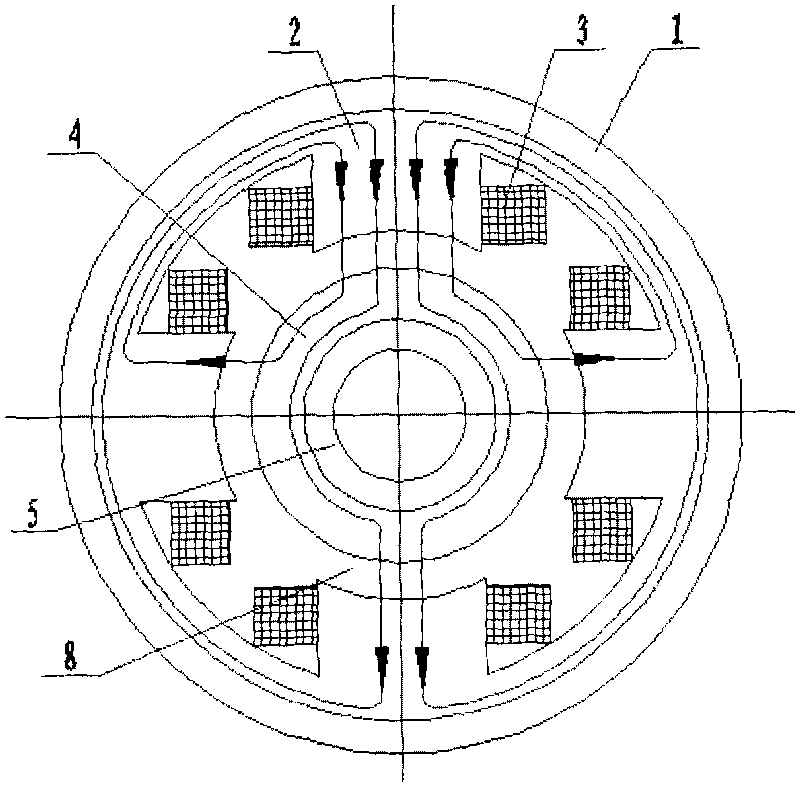

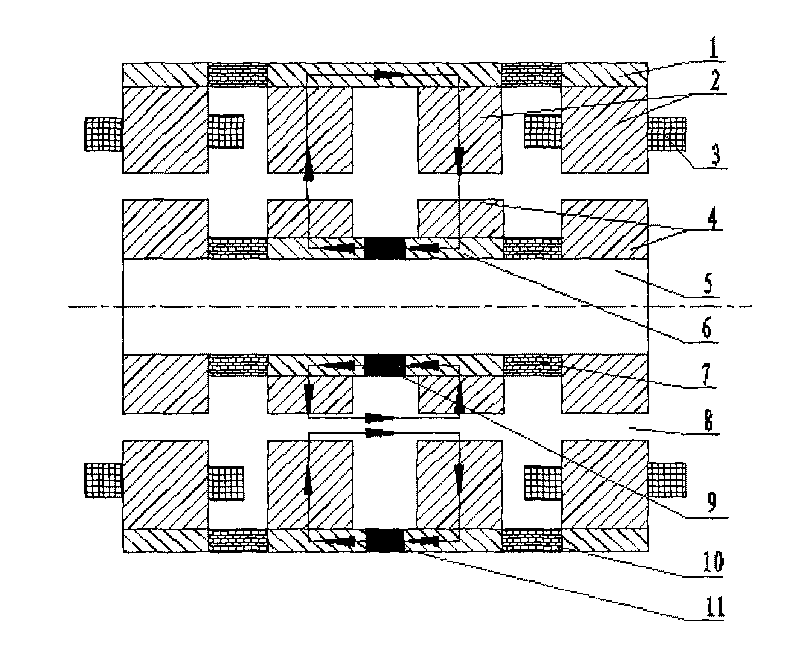

[0009] Such as figure 1 and figure 2 As shown, it is the basic implementation form of the technical solution of the present invention, which consists of 2 outer magnetic rings 1, 3 outer magnetic half rings 1, 1 permanent magnetic ring 9, 1 permanent magnetic half ring 11, and 12 stators Iron core 2, 8 excitation coils 3, 2 inner magnetic rings 6, 4 rotor cores 4, 12 air gaps 8, 2 inner magnetic isolation rings 7, and 2 outer magnetic isolation rings 9. Each stator core 2 includes 4 electromagnetic poles in the positive and negative directions of the X-axis and Y-axis, and 2 permanent magnet poles in the positive and negative directions of the Y-axis. The stator cores at the left and right ends form 8 electromagnetic poles and 4 A permanent magnetic pole, an excitation coil 3 is wound on the electromagnetic pole, an outer magnetic ring 1 is outside the stator core 2, and the outer magnetic ring 1 is connected with the outer magnetic ring 10, and between the two outer magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com