Improved contact box for high-voltage switchgear

A high-voltage switchgear and contact box technology, applied in switchgear parts, switchgear guards/guards, guards/blinds that prevent contact with contacts, etc. It can increase the insulation distance, strengthen the insulation protection ability, and reduce the amount of partial discharge due to problems such as large amplification and switch cabinet safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

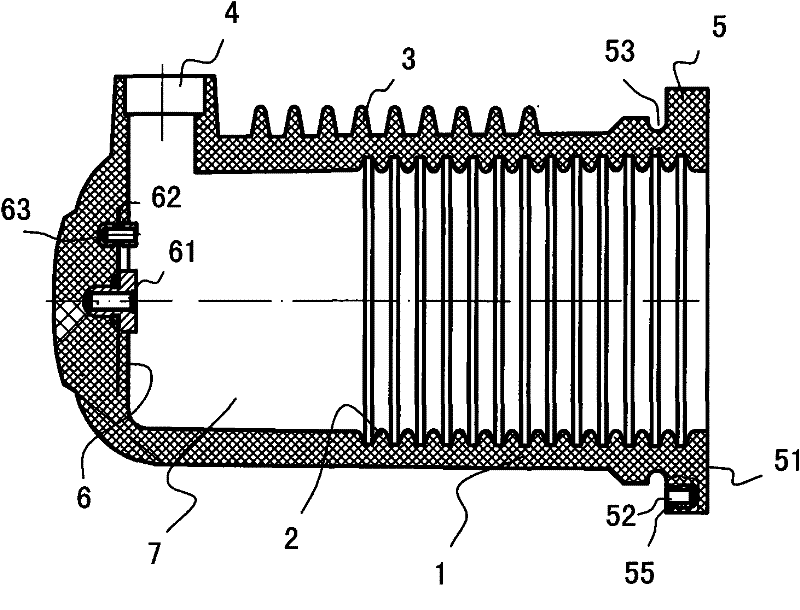

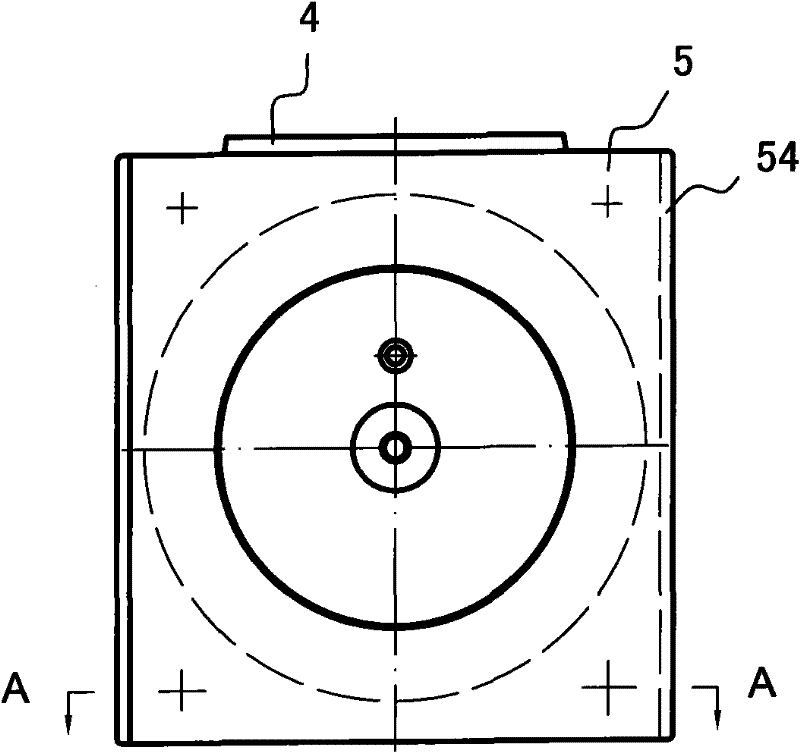

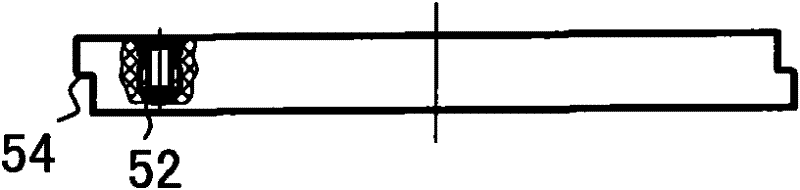

[0017] see figure 1 , and combined with figure 2 and image 3 . figure 1 The contact box in the box is placed horizontally, the right mounting flange 5 is square, and its edge has four fixed mounting screw holes 52, and the openings of the fixed mounting screw holes 52 are set on the inner plane 55 of the mounting flange 5, as The purpose of this change is to make the exposed part of the fastening bolt screwed on the fixed mounting screw hole 52 face away from the outer plane 51 of the mounting flange end, thereby increasing the creepage between the contact arm of the circuit breaker in the use state distance. The semicircular groove 53 on the cylindrical body 1 is mainly used to prevent the corona discharge phenomenon of the cabinet body to the cylindrical body 1 after installation, and the four fixing screw holes 52 accept metal fixing bolts to fix the contact box on the metal plate of the cabinet body On the other hand, semiconductor aprons or semiconductor paint can e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com