Ventilation window of package

A technology for packaging and ventilation windows, applied in the field of ventilation windows, can solve the problems of large water loss, discoloration, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

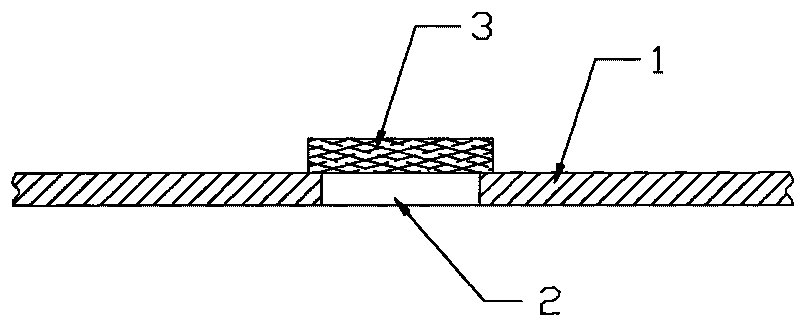

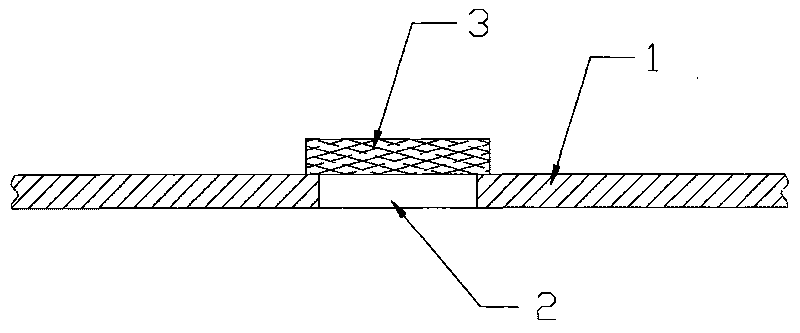

[0026] Example 1, as shown in the figure, for the PE fresh-keeping bag used for fresh food packaging, a cross-shaped air vent 2 is opened on the fresh-keeping bag 1, and a circular microporous superfine fiber non-woven fabric with a heat-sealing diameter of 1 cm is covered on the air vent. The membrane 3, forms a breathable window. The microporous ultrafine fiber non-woven membrane 3 has a pore diameter of 0.05-3 μm, of which the pore diameter of 0.08-0.5 μm accounts for about 97% of the number of openings, and the pore diameter of 0.6-3 μm accounts for about 3% of the number of openings. The fibrous non-fabric membrane 3 is made of hydrophobic PP, and the fiber fineness is 0.01-0.1 den. The area of the ventilation window is 0.8cm 2 , the microporous microfiber non-woven membrane 3 has a thickness of 0.5mm, and can hold 0.2mg of powdered preservative under the condition of not affecting the air permeability. The fresh-keeping bag adopting the ventilation window of the pres...

Embodiment 2

[0027] Embodiment 2, as shown in the figure, is used for the 10kg packing box of fruit preservation, has twelve square vents 2 altogether on packing case 1 top and side, sticks microporous microfiber non-woven film on vent 2 3. A breathable window is formed. The microporous ultrafine fiber non-woven membrane 3 has a pore size of 0.01-10 μm, wherein the pore size of 0.01-0.5 μm accounts for about 95% of the number of openings, the pore size of 0.6-1 μm accounts for about 4% of the number of openings, and the pore size of 1-0. 10 μm accounts for about 1% of the number of openings. The microporous superfine fiber non-woven membrane 3 is manufactured by a hydrophobic PP melt-blown method, and the fiber fineness is 0.1-0.8 den. The area of each ventilation window is 25cm 2 , the thickness of the microporous superfine fiber non-woven membrane 3 is 0.6mm, and its opening ratio is above 90%.

Embodiment 3

[0028] Example 3, as shown in the figure, for a composite fresh-keeping bag used for fresh food packaging, when one side of the fresh-keeping bag 1 is heat-sealed and sealed, a microporous ultrafine fiber non-woven film 3 is sandwiched between the two joints, Respectively heat-seal with the limit of microporous superfine fiber non-woven membrane 3, has formed the wide 1cm, the long 50cm strip-shaped breathable window. This method is suitable for thin and long strips or large fresh-keeping bags. The production efficiency of the fresh-keeping bags is high and the fresh-keeping effect is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Fiber fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com