An upflow anaerobic sludge digester

An upflow anaerobic and digester technology, applied in sludge treatment, biological sludge treatment, waste fuel, etc., can solve the problems of low ability to degrade organic matter and produce biogas, long hydraulic retention time, and high energy consumption. Achieve the effects of saving energy consumption, improving mass transfer conditions, and shortening HRT

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

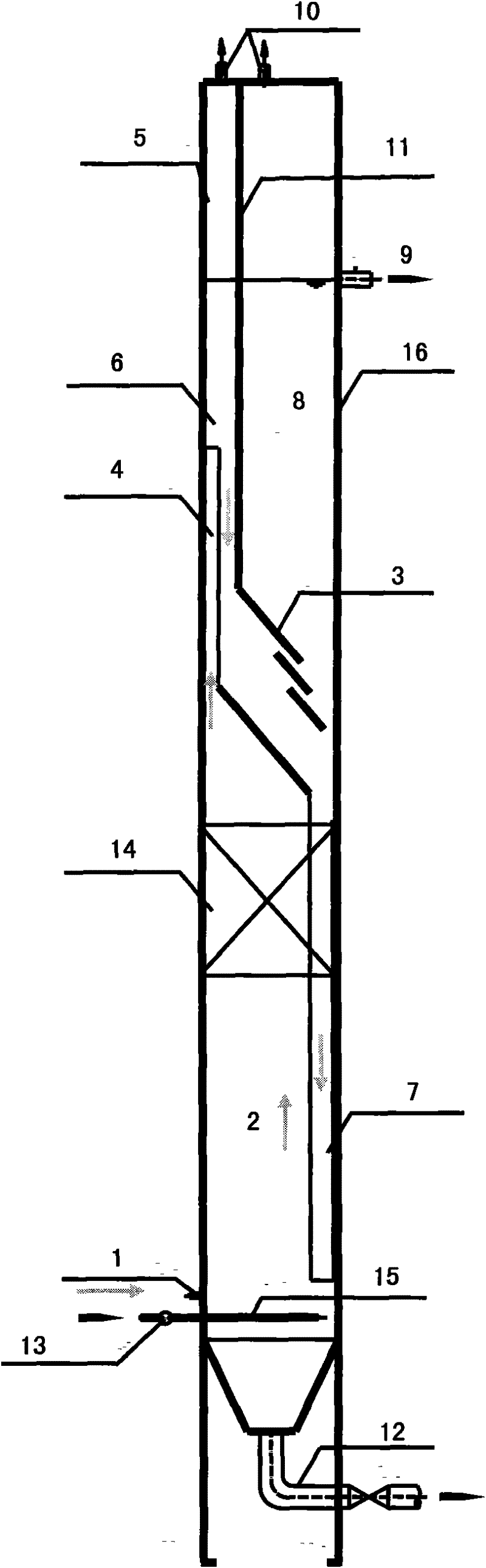

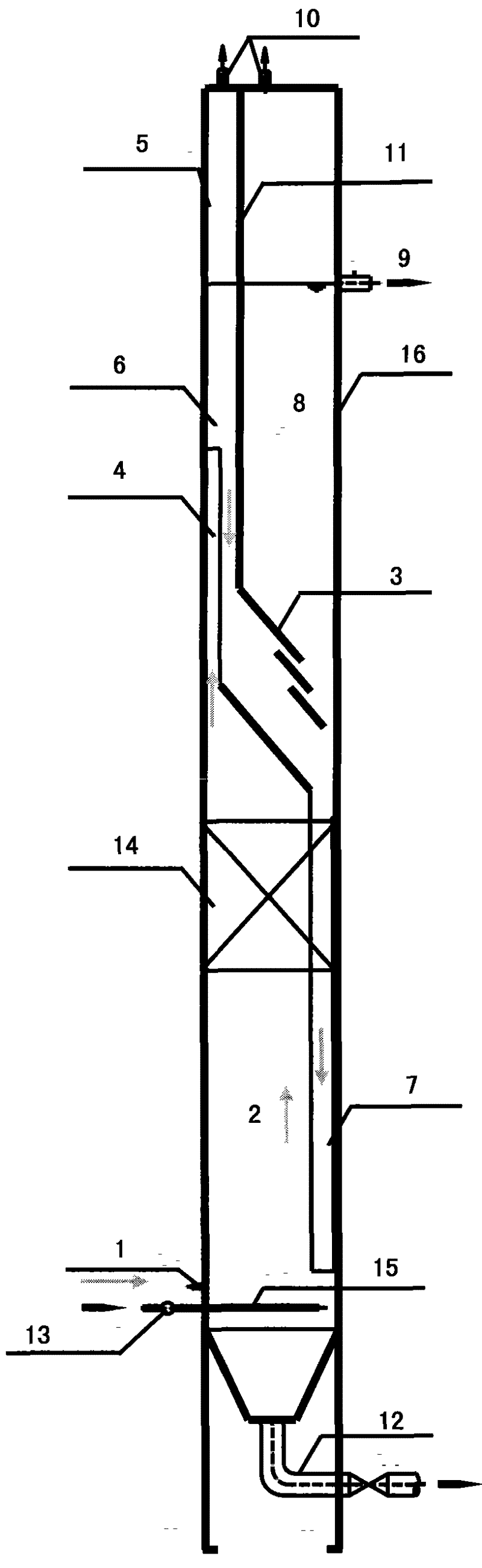

[0012] The structure of the upflow anaerobic sludge digester provided by the present invention includes a digester main body 16, a mud inlet pipe 1, a mud outlet pipe 12, and a biogas pipe 10 arranged on the top of the digester. A reaction zone 2 is provided at the lower part of the digester main body 16, a filler 14 is provided at the top of the reaction zone, a biogas aerator 15 is installed at the bottom of the reaction zone, and is connected with a biogas pump 13, and in the middle of the digester main body 16 The upper part is provided with a downflow zone 6 and a settling zone 8, the upper part of the settling zone 8 is provided with a supernatant liquid pipe 9, and the upper part of the digester main body 16 is provided with a gas-liquid separation zone 5; the reaction zone 2 passes through the upflow tube 4 is communicated with the downflow area 6, most of the sedimentation area 8 and the downflow area 6 are separated by partitions, the bottom is connected through the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com