Hot stuffy processing device for steel slag

A processing device and a hot and stuffy technology, applied in the field of steel-making slag recycling and processing devices, can solve the problems of prominent safety problems in the production process, increased pressure of the stuffy furnace, difficult maintenance, etc., and achieve stable and controllable product quality and improved production efficiency. , the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

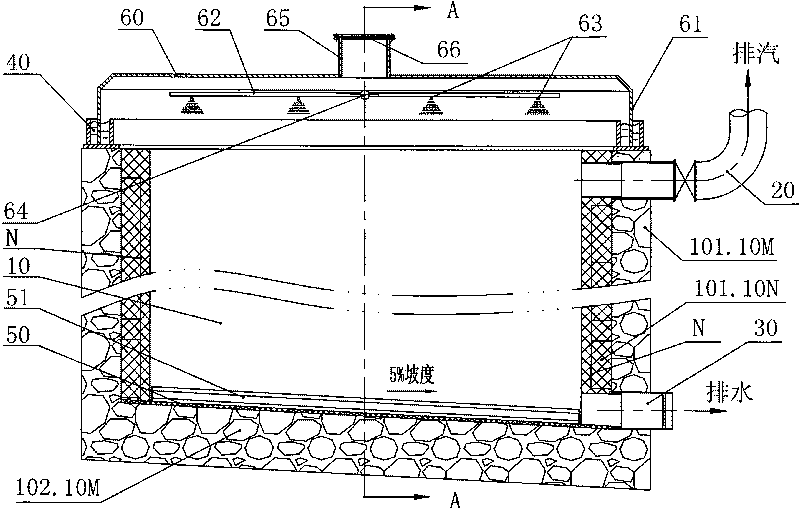

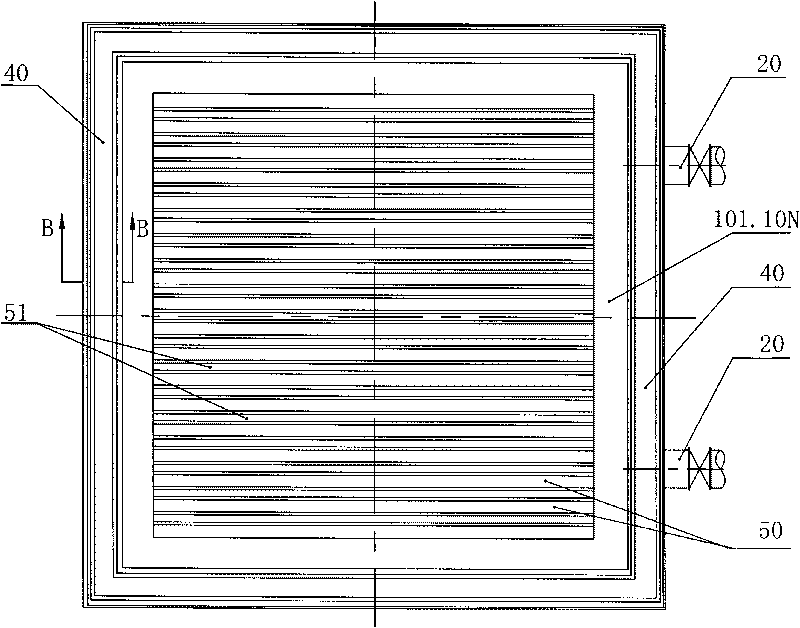

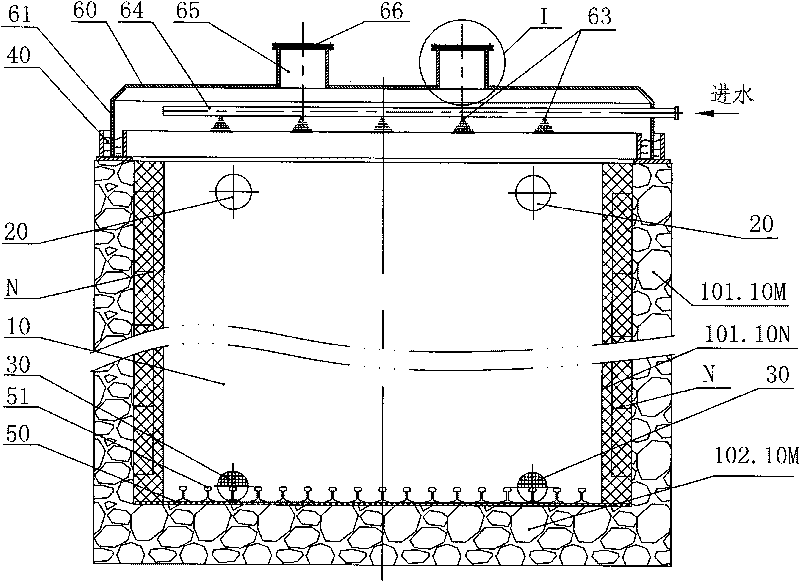

[0034] Such as Figure 1-8 , which are the main schematic diagram of the structure of the embodiment of the hot stuffy treatment device for steel slag of the present invention and the schematic diagrams from various angles of view, respectively. The upper end is open, the upper part of the tank wall 10 is provided with an exhaust pipe 20, the lower part of the tank wall 10 is provided with a drain pipe 30, and a circle of water seal grooves 40 with a U-shaped cross section is provided along the upper opening of the tank wall 10, and the tank wall 10 includes a primary The outer wall 10M of the heat-resistant concrete formed by pouring and tamping, the side 101 of the tank wall 10 also includes an inner wall 10N formed by one-time pouring and tamping of the steel fiber reinforced refractory castable; the outer wall 10M includes a steel mesh M (not shown ), embedded parts (not shown) are evenly distributed on the reinforced mesh M, and the inner wall 10N includes a reinforced me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com