Underground oil- water two-phase flow rate measuring method used for low production liquid horizontal well

A technology for flow measurement and horizontal wells, which is applied in the directions of liquid/fluid solid measurement, flow measurement/mass flow measurement, etc., and can solve problems such as inability to meet dynamic monitoring of low-production liquid horizontal wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings:

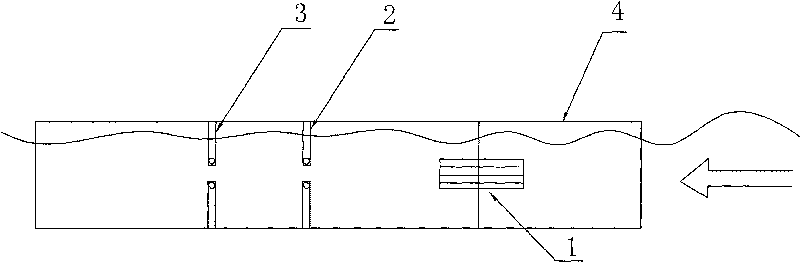

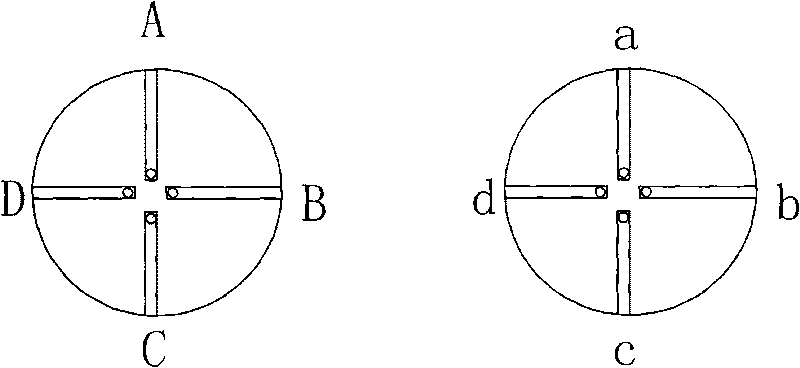

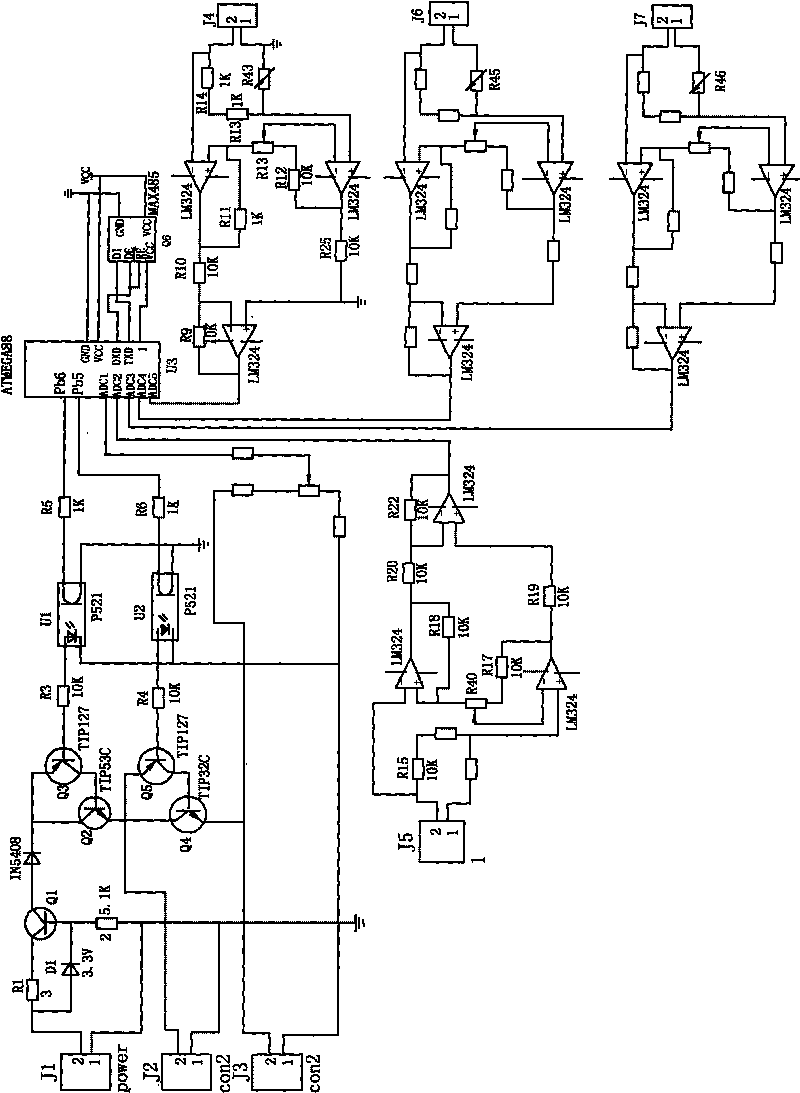

[0017] The downhole oil-water two-phase flow measurement method for a low-production horizontal well described in the present invention is specifically composed of the following steps: first, a circular measuring pipe section 4 with an inner diameter of D is placed in parallel downhole along the fluid flow direction, and the measuring pipe section is It can be made of stainless steel, but requires a bracket inside to mount the heat generator and temperature sensor. After that, as figure 1 As shown, a cylindrical heat source generator 1 capable of generating heat pulses is installed at the axial center of the measuring tube section, and two temperature sensor arrays with a distance L are installed downstream of the heat source generator, which are called No. 1 temperature sensor and No. 2 temperature sensor. The heat source generator is controlled by a single chip mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com