Mould for molding super-thin soft ferrite magnetic core

A soft ferrite and molding die technology, applied in ceramic extrusion dies and other directions, can solve the problems of warping, unusable, and short moving time of products, reducing poor warping deformation, increasing manufacturing costs, and designing simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

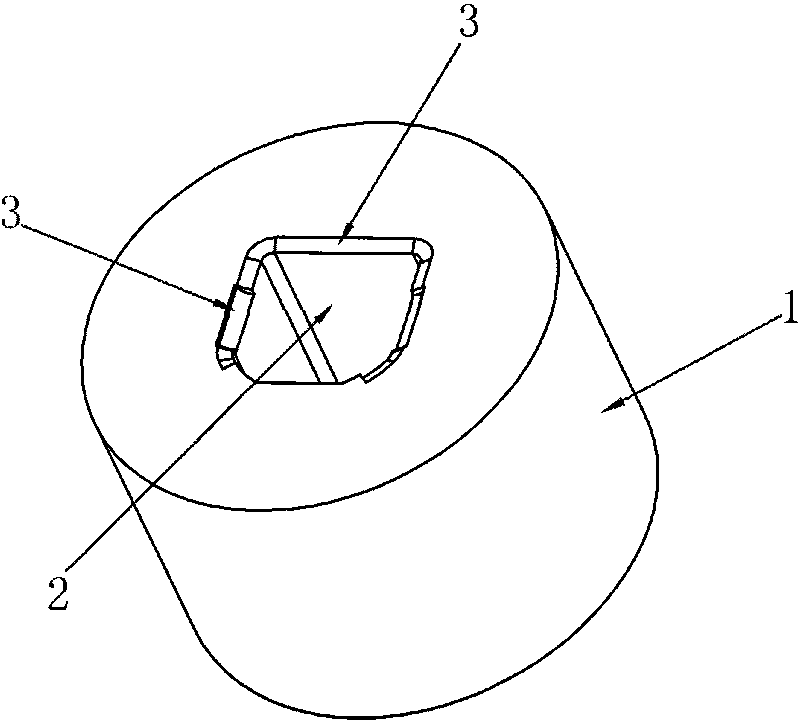

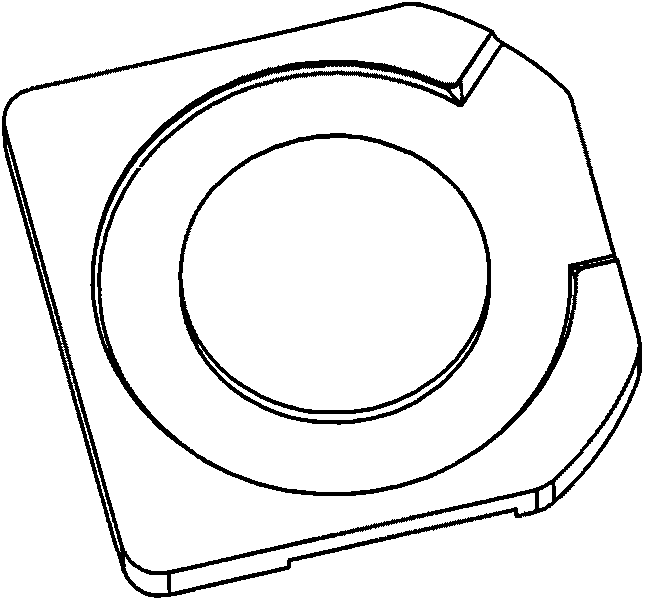

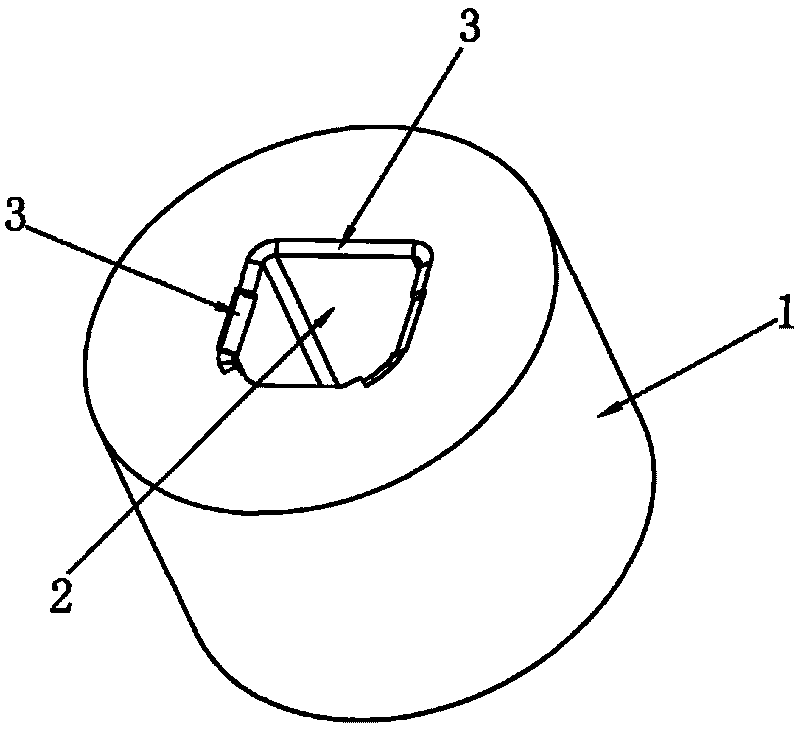

[0011] refer to figure 1 , an ultra-thin soft ferrite core molding die disclosed by the present invention, comprising a master die 1, a die hole 2 is arranged on the master die 1, a spraying groove 3 is arranged on the edge of the die hole 2, and the spraying The trough is one or more side edges set according to the shape of the product. The depth of the spray trough designed for different side edges is different, so as to cooperate with the molding action during molding, and the powder of the small volume is passed through the spray trough in the molding process. During the process, the excess powder is sprayed out to achieve the purpose of consistent density of each part, so that the density of each part can be made uniform when molding the above-mentioned products, and the warping and deformation caused by the difference in density can be avoided or minimized, so as to achieve mass production. The purpose of producing ultra-thin (height less than 0.5mm) soft ferrite cores ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com