Method for producing foam honeycomb core

A production method and technology of honeycomb core, applied in the field of materials, can solve the problems of honeycomb board heat preservation, sound insulation effect is not very good, sound insulation effect is poor, occupying space, etc., achieve excellent sound insulation effect, speed up production efficiency, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

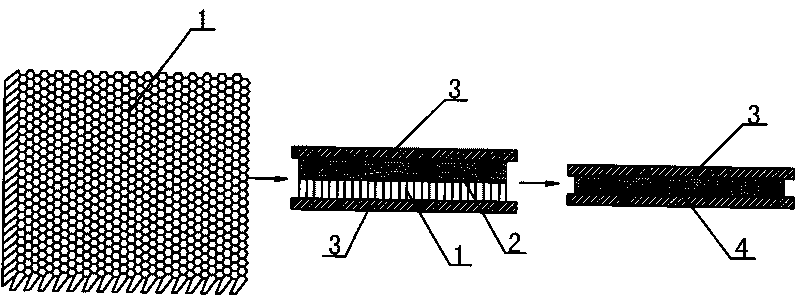

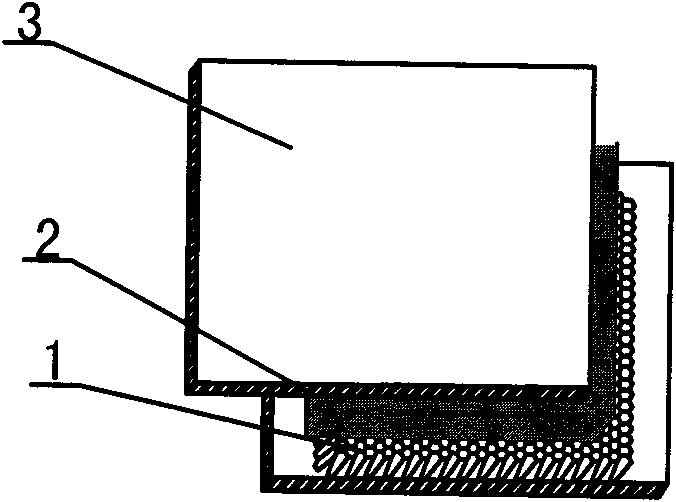

[0021] Such as Figure 1-4 Shown, the manufacture method of foam honeycomb core of the present invention mainly comprises the following steps:

[0022] (1) Stretch the regular hexagonal aluminum honeycomb core 1: use manual or stretching machine to draw and shape;

[0023] (2) The size of the foam material 2 is made according to the stretched size of the honeycomb core 1: the length, width, and height are respectively consistent with the honeycomb core 1 or customized according to specific needs. The stretched size of the honeycomb core 1 is 2400mm long , 1200mm wide and 20mm high, the foam is made into 2400mm×1200mm×20mm;

[0024] (3) Flat pressing process: put the honeycomb core 1 and the foam material 2 into the flat press 3 after stacking, and adjust the pressure of the flat press 3 according to the density, hardness, and conditions of the foam. It is advisable that the material 2 is just completely pressed into the honeycomb core 1 without destroying the honeycomb struc...

Embodiment 2

[0027] Such as Figure 1-4 Shown, the manufacture method of foam honeycomb core of the present invention mainly comprises the following steps:

[0028] (1) Aramid paper honeycomb core (0.08mm paper thickness × 8mm side length) can be stretched and heated to shape, and can be sliced after twice dipping and heat curing;

[0029] (2) The size of the foam material 2 is made according to the stretched size of the honeycomb core 1: the length, width, and height are respectively consistent with the honeycomb core 1;

[0030] (3) Flat pressing process: stack the honeycomb core 1 and the foam material 2 and put them into the platform. One side of the platform is flat, and the other side directly applies pressure. The pressure is large enough to press the foam material 2 completely It is advisable not to damage the honeycomb structure in the honeycomb core 1;

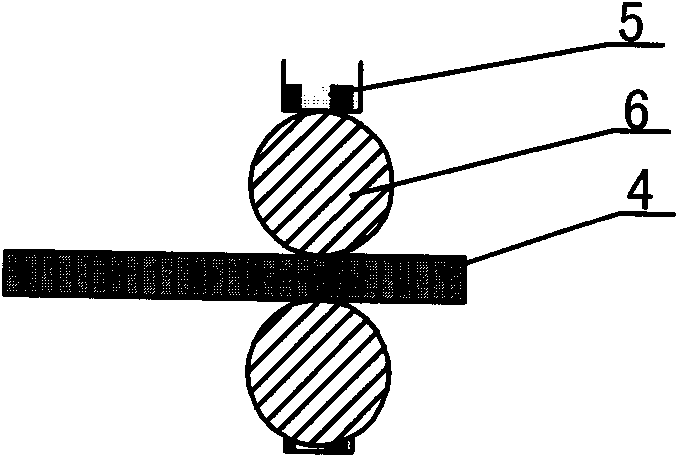

[0031] (4) Make a honeycomb panel with the foam honeycomb core 4, apply glue through the glue groove 5 on the back of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com