Sludge circular flocculation-membrane filtration reactor

A technology of membrane filtration and reactor, which is applied in the direction of filtration circuit, filtration separation, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of ineffectiveness and excessive use of chemicals, and achieve large floc group size and high efficiency. The effect of small amount and long-term stable operation is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

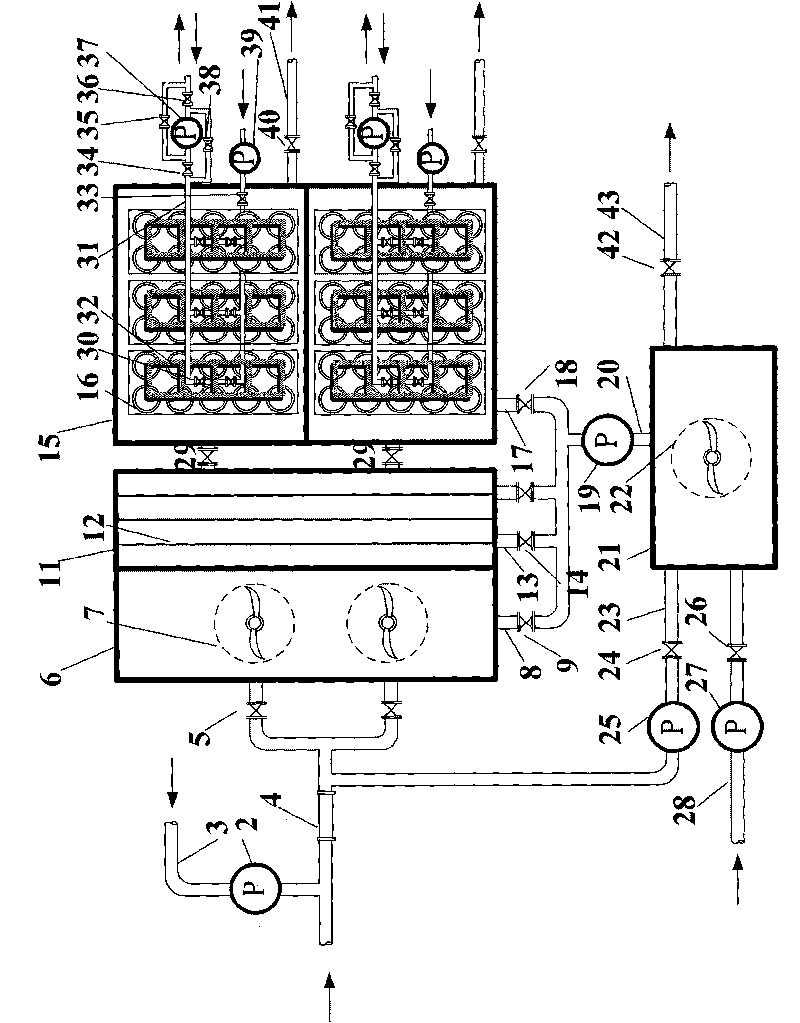

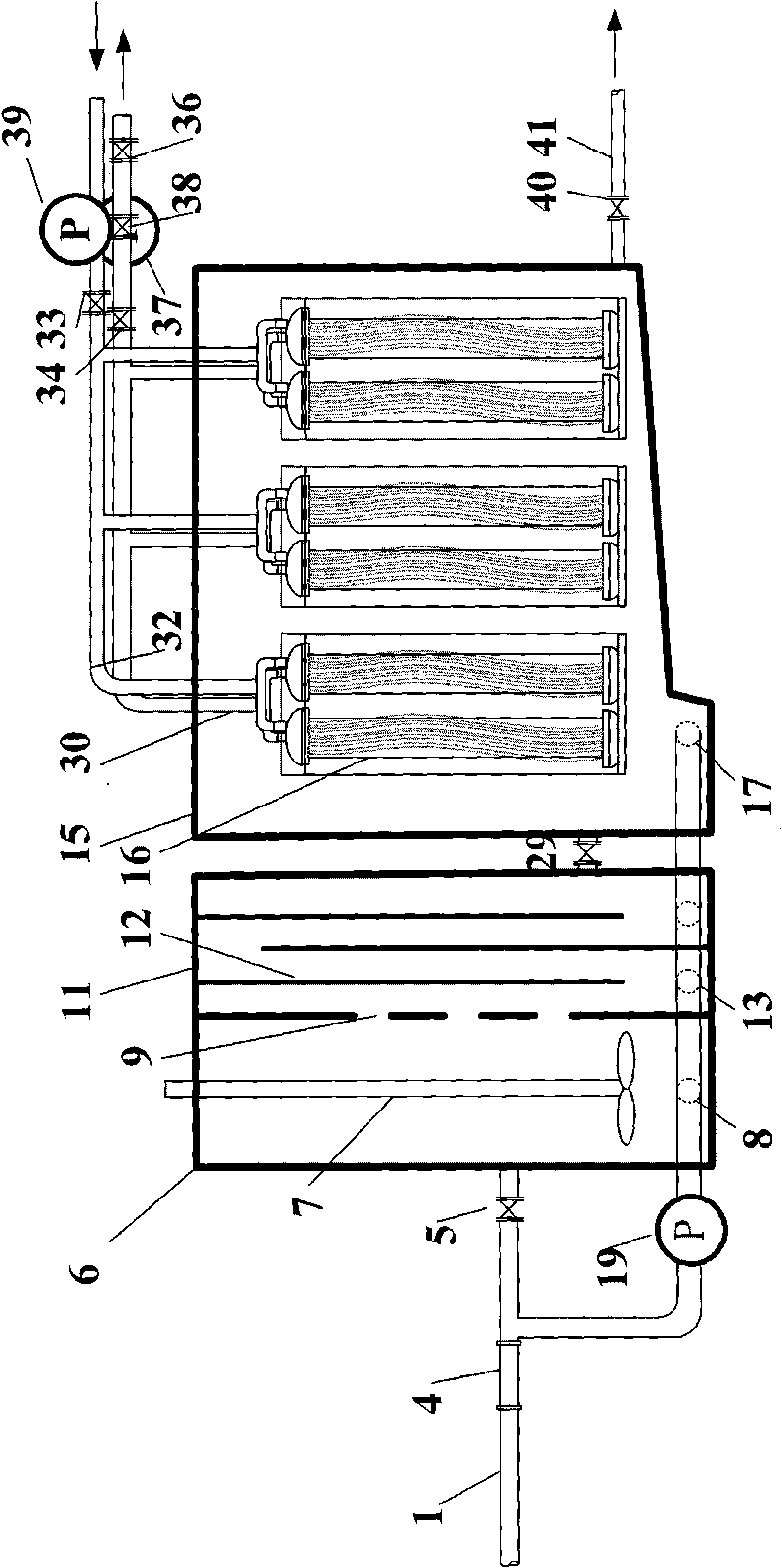

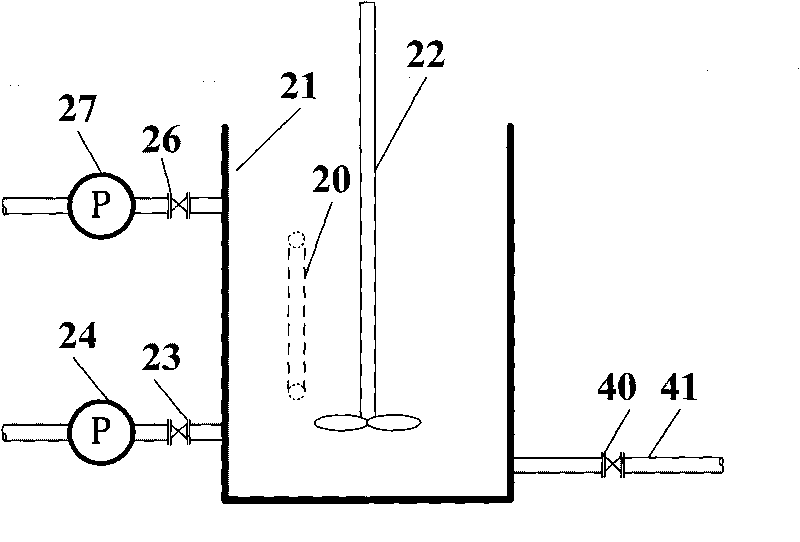

[0017] A sludge circulation flocculation-membrane filtration reactor includes a rapid mixing chamber 6 , a flocculation chamber reaction chamber 11 , a membrane filtration chamber 15 and a sludge adjustment chamber 21 . The flocculant dosing pipeline 3 is connected to the water inlet main pipe 1 through the flocculant dosing pump 2, and the water inlet main pipe 1 is connected to the sludge circulation pipe 23 after passing through the pipeline mixer 4, and then enters the rapid mixing chamber through the mixed liquid distribution pipe 5 6. The fast mixing chamber 6 is equipped with a mixing and stirring device 7, and a group of perforated flower walls are arranged between the fast mixing chamber 6 and the flocculation reaction chamber 11, and the flocculation reaction chamber 11 is provided with a deflector 12, and the flocculation reaction chamber 11 and the membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com