Hydraulic power automation water treatment aeration cycle system

A circulation system and water treatment technology, applied in water/sewage multi-stage treatment, light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of slow filter filtration speed, no use of sterilization equipment, and increased maintenance workload and other problems, to achieve the effect of reducing maintenance workload, eliminating corrosion phenomenon, and less post-maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

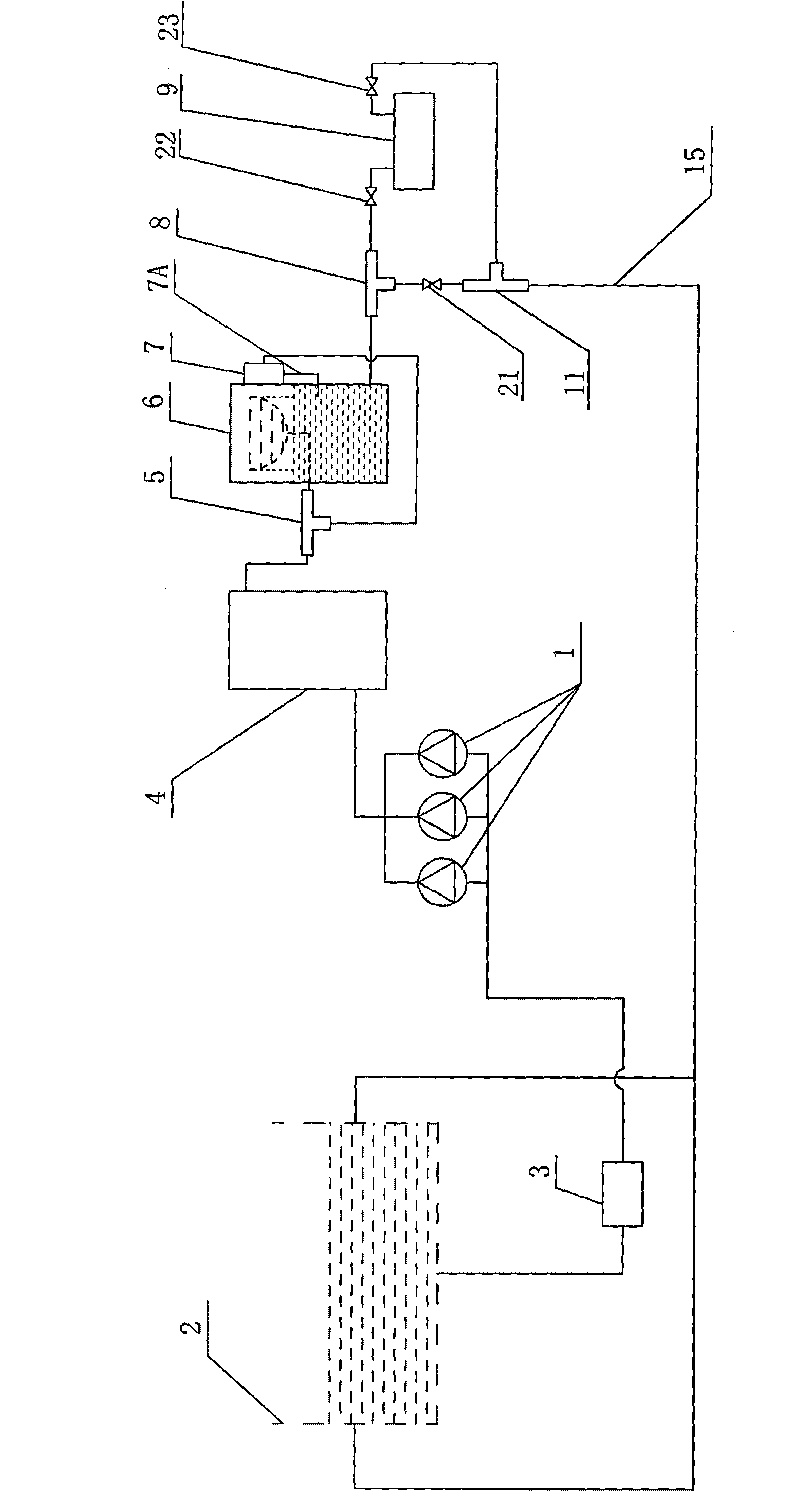

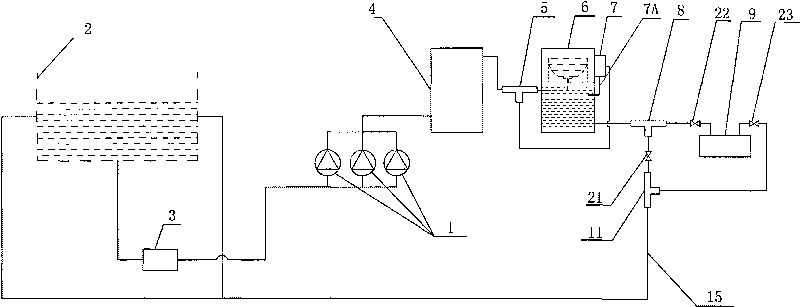

[0012] Such as figure 1 As shown, the hydraulic automatic water treatment aeration circulation system of the present invention includes a water pump group 1 connected to one side of the water storage tank 2, and a filter net decontamination device 3 is arranged in series between the water pump group 1 and the water storage tank 2, and the water pump group 1 The water outlet of the water outlet is connected with a high-speed composite filter material filter 4 through a pipeline, and the water outlet of the high-speed composite filter material filter 4 is connected with the water inlet of a drug-dissolving device tee 5, and an outlet of the drug-dissolving device tee 5 The water outlet is connected with an aeration box 6 through a pipeline, and the other water outlet of the drug dissolver tee 5 is connected with a gravity type drug dissolver 7 through a pipeline, and the gravity type drug dissolver 7 is fixedly connected to the aeration box 6 And its outlet 7A is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com