Nano-silver anion tide solidifying matte floor board paint

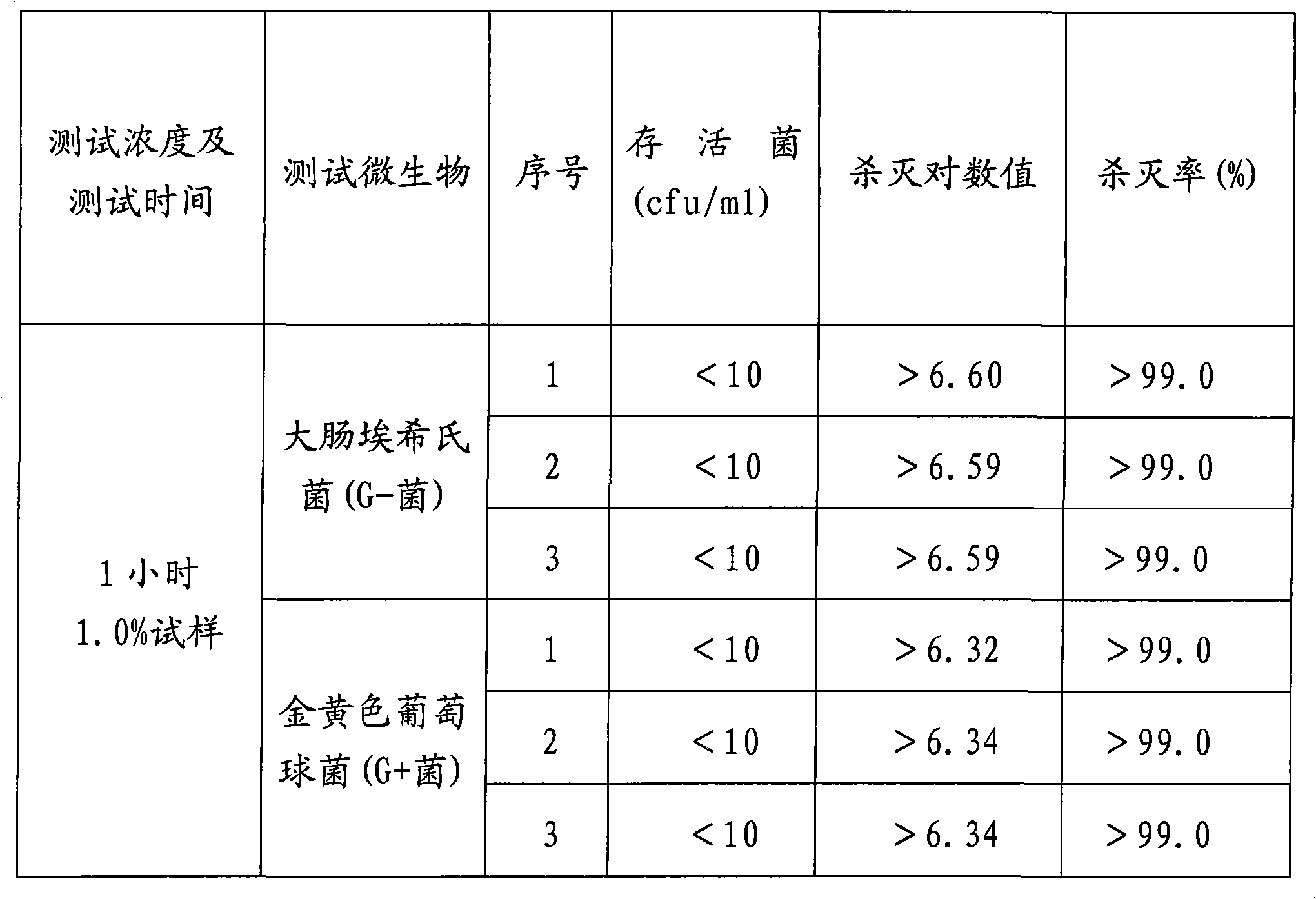

A moisture-curing, nano-silver technology, used in the field of organic polymer material coatings, can solve problems such as inability to play and functional additives cannot be reasonably arranged, and achieve the effect of improving usability, system and formula optimization, and tough paint film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0039] Component A: composed of moisture-cured polyurethane resin Taiwan Jiehua 6308-60;

[0040] Component B: According to the proportion by weight, put 71.7 parts of butyl acetate and 6 parts of Eastman CAB-531-1 into the dispersion tank, and disperse into Eastman CAB-531 at a speed of 600 rpm -1 Dissolve completely; Add 2 parts of EFKA-4010, 0.3 parts of BYK-141, 0.7 parts of Texogel MP100, 2 parts of Lubrizol 1400SF, 10 parts of Grace C906, and disperse for 25 minutes at a speed of 1500 rpm to fineness ≤30 microns; add 0.3 parts of BYK-323, 5 parts of Longnuo brand G series type II negative ion additive, 2 parts of nano-silver antibacterial additive AGS-MB3000, and disperse for 15 minutes at a speed of 600 rpm to make it component B;

[0041] When in use, the ratio of component A:component B=1:0.7 in parts by weight can be mixed evenly.

Embodiment II

[0043] Component A: composed of moisture-cured polyurethane resin Jiangmen Paint PJ6803-60;

[0044] Component B: Mix 71.6 parts of butyl acetate and 7 parts of Eastman CAB-553-0.4 in parts by weight: put them into the dispersion tank, and disperse them into Eastman CAB-553 at a speed of 700 rpm -0.4 is completely dissolved; add BYK-110 1.5 parts BYK-052 0.4 parts, Bentone SD-1 0.8 parts, Clariant 9615A 2 parts, Grace ED-2 8 parts, and disperse for 20 minutes at 1200 rpm. To a fineness of ≤25 microns; add 0.2 parts of tego-450, 6 parts of Tianshuang brand DMD698 negative ion additive, 2.5 parts of nano-silver antibacterial additive AGS-MB3000, and disperse for 20 minutes at a speed of 500 rpm. component B;

[0045]When in use, the ratio of component A:component B=1:0.5 in parts by weight can be mixed evenly.

Embodiment III

[0047] Component A: composed of moisture-cured polyurethane resin Taiwan Jiehua 6308-60;

[0048] Component B: put 69.0 parts of butyl acetate and 5 parts of Eastman CAB-531-1 into the dispersion tank according to the weight ratio, and disperse at the speed of 600 rpm until Eastman CAB-531-1 is completely Dissolve; add 1.5 parts of EFKA-4010, 0.4 parts of BYK-141, 0.7 parts of Bentone SD-1, 3 parts of Lubrizol 1400SF, 12 parts of Grace C906, and disperse for 30 minutes at a speed of 1300 rpm until fineness ≤25 microns; add 0.4 parts of BYK-323, 5 parts of Longnuo brand G series II negative ion additive, 3 parts of nano-silver antibacterial additive AGS-MB3000, and disperse for 20 minutes at a speed of 500 rpm to make it component B;

[0049] When in use, the ratio of component A:component B=1:0.6 in parts by weight can be mixed evenly.

[0050] Names of main raw materials, technical indicators

[0051] 1. Moisture curing polyurethane resin 6308-60

[0052] Manufacturer: Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com