Wavelike steel webplate shear wall structure

A technology of corrugated steel webs and shear walls, which is applied to walls, building components, building structures, etc., can solve the problems of affecting the construction height of high-rise buildings, the effect of shear resistance is not obvious, and increasing the weight of buildings, so as to improve space utilization High efficiency, easy on-site construction, and the effect of reducing the weight of the building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

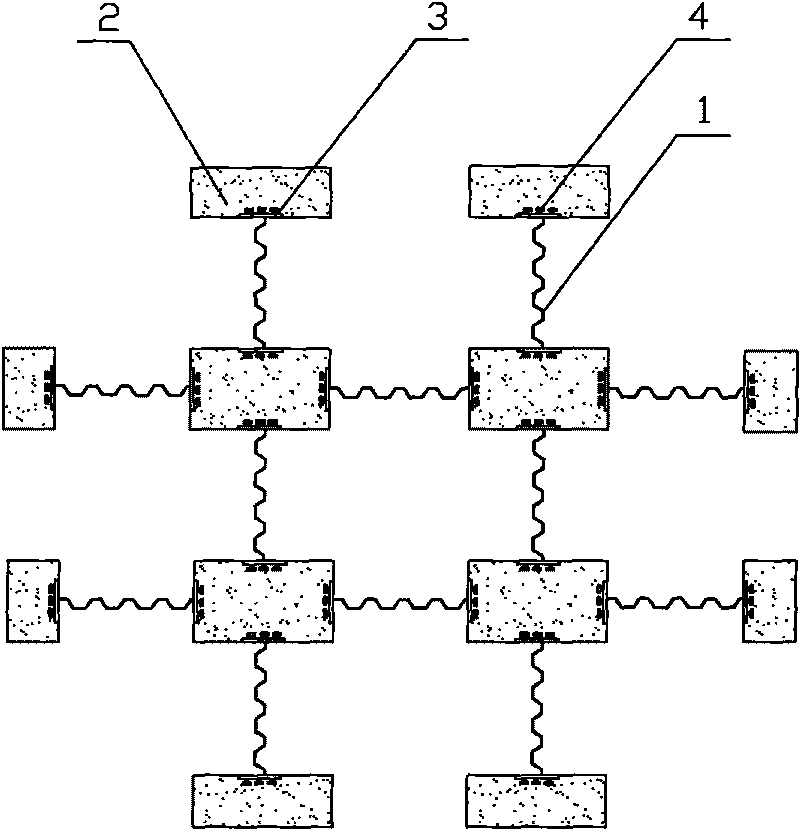

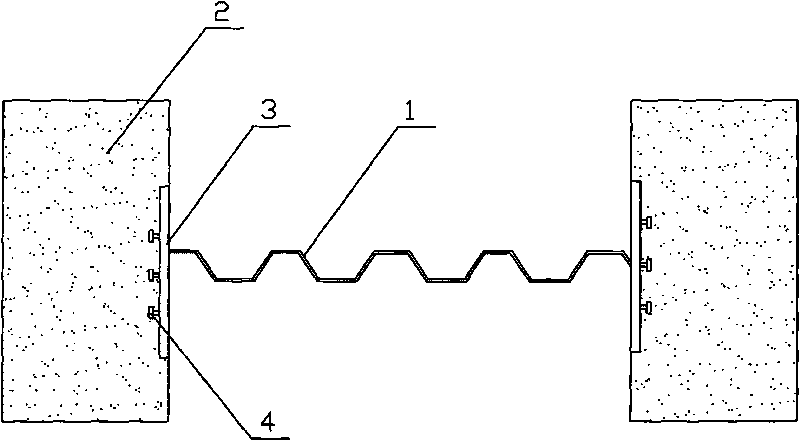

[0019] Shear wall structures with corrugated steel webs, such as figure 1 , 2 , 4, including the corrugated steel web 1 and the reinforced concrete beams and columns 2 arranged at both ends of the corrugated steel web 1, the surface of the corrugated steel web 1 is prepared with a roughness of 60 μm, and the corrugated steel web 1 and the steel bars arranged on the The steel plate 3 inside the concrete beam column 2 is welded, the steel plate 3 is poured on the surface of the reinforced concrete beam column 2, the corrugated steel web 1 is perpendicular to the plane where the steel plate 3 is located, the steel plate 3 is provided with a rivet 4, and the rivet 4 is completely poured into the reinforced concrete beam Inside column 2. The corrugated steel web 1 is composed of multiple corrugated steel web sub-plates 11 , and the corrugated steel web sub-plates 11 are connected by bolts 5 .

Embodiment 2

[0021] Shear wall structures with corrugated steel webs, such as figure 1 , 2 , 4, including the corrugated steel web 1 and the reinforced concrete beams and columns 2 arranged at both ends of the corrugated steel web 1, the surface of the corrugated steel web 1 is prepared with a roughness of 400 μm, and the corrugated steel web 1 is arranged on the reinforcement The steel plate 3 inside the concrete beam column 2 is welded, the steel plate 3 is poured on the surface of the reinforced concrete beam column 2, the corrugated steel web 1 is perpendicular to the plane where the steel plate 3 is located, the steel plate 3 is provided with a rivet 4, and the rivet 4 is completely poured into the reinforced concrete beam Inside column 2. The corrugated steel web 1 is composed of multiple corrugated steel web sub-plates 11 , and the corrugated steel web sub-plates 11 are connected by bolts 5 .

Embodiment 3

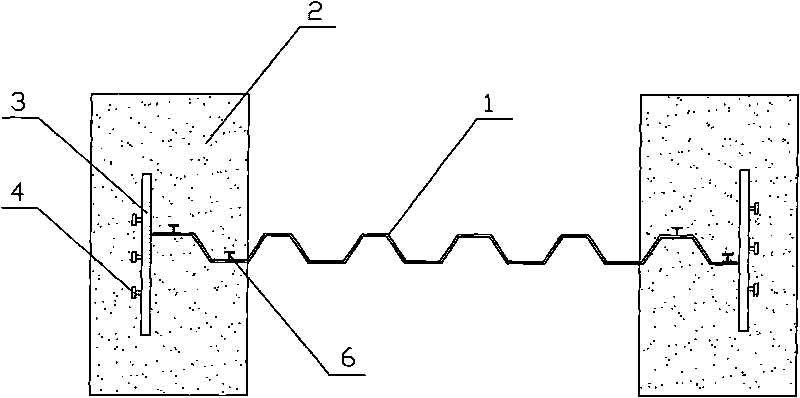

[0023] Shear wall structures with corrugated steel webs, such as figure 1 , 2 , 3, including the corrugated steel web 1 and the reinforced concrete beams and columns 2 arranged at both ends of the corrugated steel web 1, the surface of the corrugated steel web 1 is prepared with a roughness of 60 μm, and the corrugated steel web 1 is arranged on the steel bar The steel plate 3 in the concrete beam column 2 is welded, and the connecting part of the corrugated steel web 1 and the steel plate 3 is poured into the reinforced concrete beam column 2 together. The corrugated steel web 1 is perpendicular to the plane of the steel plate 3, and the corrugated steel web 1 and the The connecting part of the reinforced concrete beam column 2 is provided with studs 6 , and the studs 6 are completely poured into the reinforced concrete beam column 2 . The corrugated steel web 1 is composed of multiple corrugated steel web sub-plates 11, and the corrugated steel web sub-plates 11 are connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com