Loading device and loading mode for use in measurement of hydrogen diffusion in stress field

A loading device and stress field technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as test structure interference, test structure data dispersion, adverse effects of hydrogen damage engineering evaluation, etc., and achieve the effect of reducing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

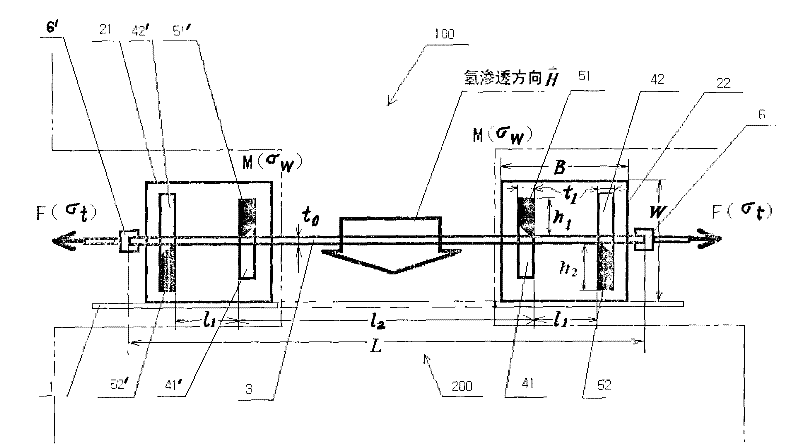

[0048] A loading device for hydrogen diffusion measurements in stress fields, such as figure 1 shown, including:

[0049] The positioning frame 1 is a rigid support arranged between the hydrogen permeation double electrolytic cells 100 and 200, on which a chute is arranged along the long axis direction of the sample to be tested;

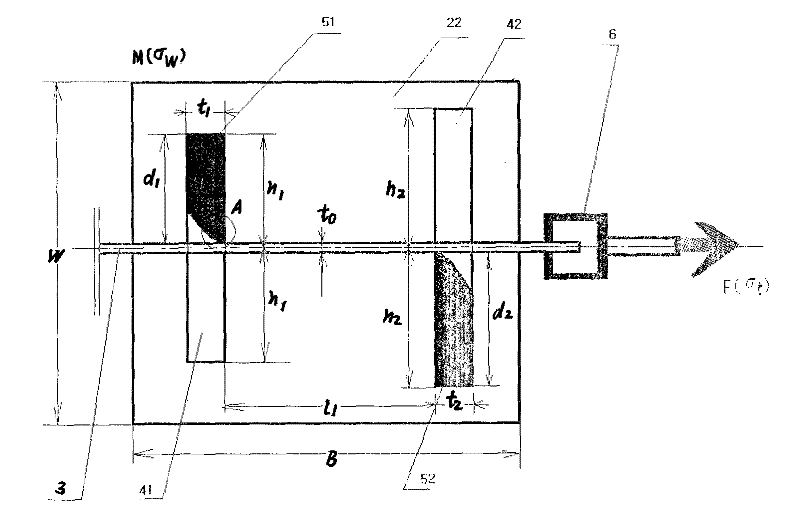

[0050] Two sets of loading frames 21 and 22 are supported by the positioning frame 1, are arranged in parallel along the long axis direction of the sample to be tested 3 and can slide along its chute in the positioning frame 1; each set of loading frames includes two main frames, which are separate On both sides of the sample to be tested 3 along the short axis direction, the sample to be tested 3 is sandwiched in it and is perpendicular to the upper and lower surfaces of the sample to be tested 3, such as figure 2 shown;

[0051]The loading windows 41, 42, 41', 42' are opened on each set of loading frames 21, 22, with the upper and lower surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com