Digital Integrated Optical Waveguide Sensor Based on Cascaded Microcavities

An integrated optical waveguide and sensor technology, applied in the field of optical sensing, can solve the problems that hinder the miniaturization of the optical sensing system, portability and low cost, and achieve the effects of easy expansion, lower requirements, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

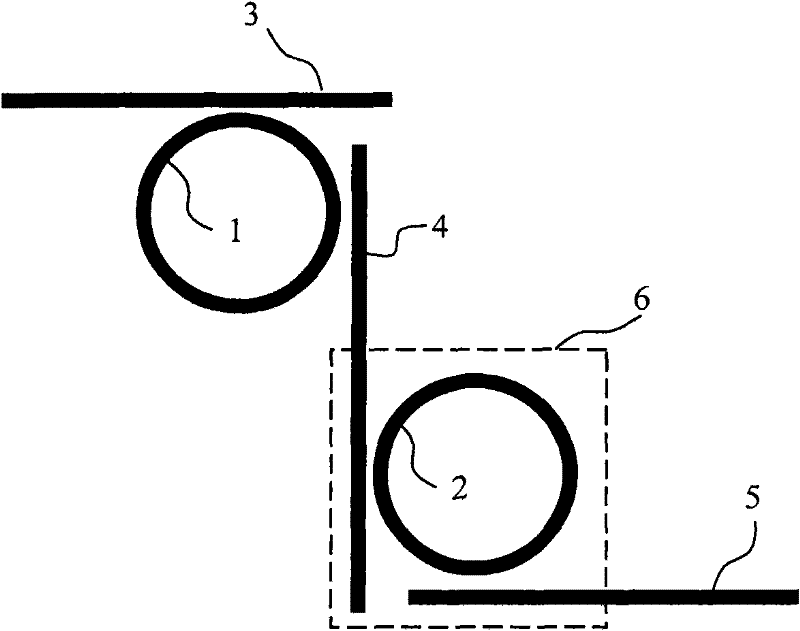

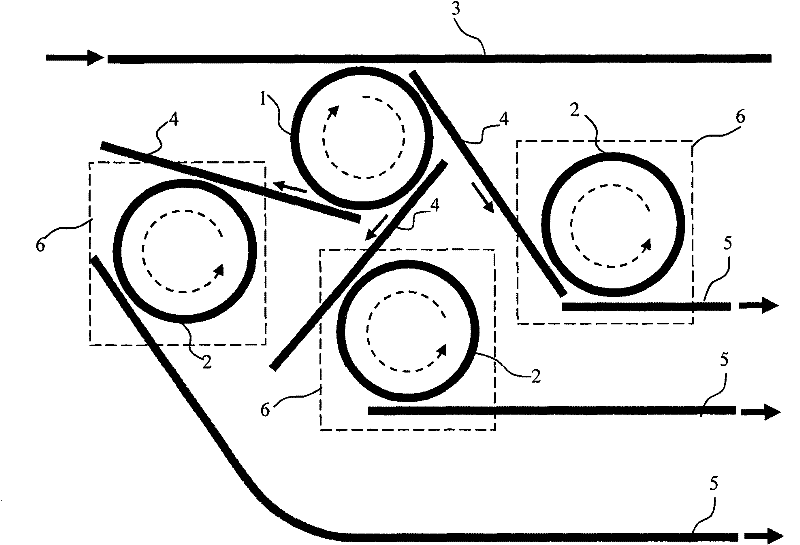

[0023] refer to figure 1 , the digital integrated optical waveguide sensor based on cascaded microcavities of the present invention includes a constant microcavity 1, an input waveguide 3, a sensing microcavity 2, a connecting waveguide 4, an output waveguide 5 and a sample tank 6 ; each sensing microcavity 2 is placed in the middle of the sample groove 6 respectively, the input waveguide 3 is located at one side of the constant microcavity 1, one end of the input waveguide 3 is coupled with the constant microcavity 1, and the other end is the light source of the entire optical waveguide sensor Access port; one end of the waveguide 4 is coupled with the constant microcavity 1, the other end of the waveguide 4 is coupled with the sensing microcavity 2, one end of the output waveguide 5 is coupled with the sensing microcavity 2, and the output waveguide 5 is coupled with the sensing microcavity 2. The other end is the sensing signal output end.

[0024] The substance to be meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com