Method for testing insulation performance of insulator and device thereof

A technology for insulation performance and detection devices, which is applied in measuring devices, measuring electrical variables, and measuring resistance/reactance/impedance, etc., which can solve problems such as inability to detect line insulators live, time-consuming and labor-intensive insulators, low efficiency, and long detection time for power grid outages. , to achieve the effects of rich human-computer interaction, accurate and reliable measurement, and high efficiency of detection operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

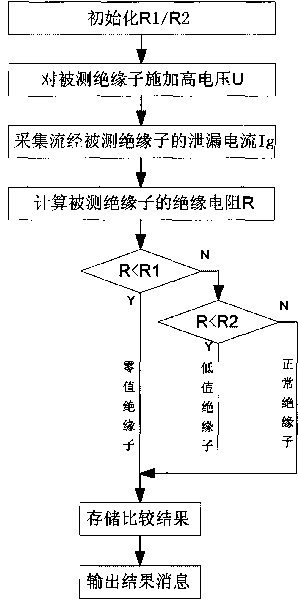

[0036] Such as figure 1 As shown, the specific implementation steps of the intelligent detection method for insulator insulation performance of the present invention are as follows:

[0037] 1) Initialize the zero-value critical resistance R1 and low-value critical resistance R2 of the insulator under test;

[0038] 2) Apply DC high voltage to the insulator under test under power failure state;

[0039] 3) Collect the leakage current flowing through the insulator under test;

[0040] 4) Calculate the insulation resistance R of the insulator under test according to the DC high voltage applied in step 2) and the leakage current collected in step 3) in combination with voltammetry;

[0041] 5) Compare the insulation resistance R calculated in step 4) with the zero-value critical resistance R1 and the low-value critical resistance R2, and then output a comparison result of the performance of the tested insulator.

[0042] In step 5), first compare the insulation resistance R wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com