Eliminator for parasitic inductance of smoothing capacitor

A technology of filtering capacitors and parasitic inductance, which is applied in the field of elimination devices for parasitic parameters of components, can solve problems such as affecting the elimination effect and secondary parasitic effects, achieves convenient control, reduces the influence of high-frequency characteristic improvement, and reduces the positive area small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in detail below in conjunction with the drawings:

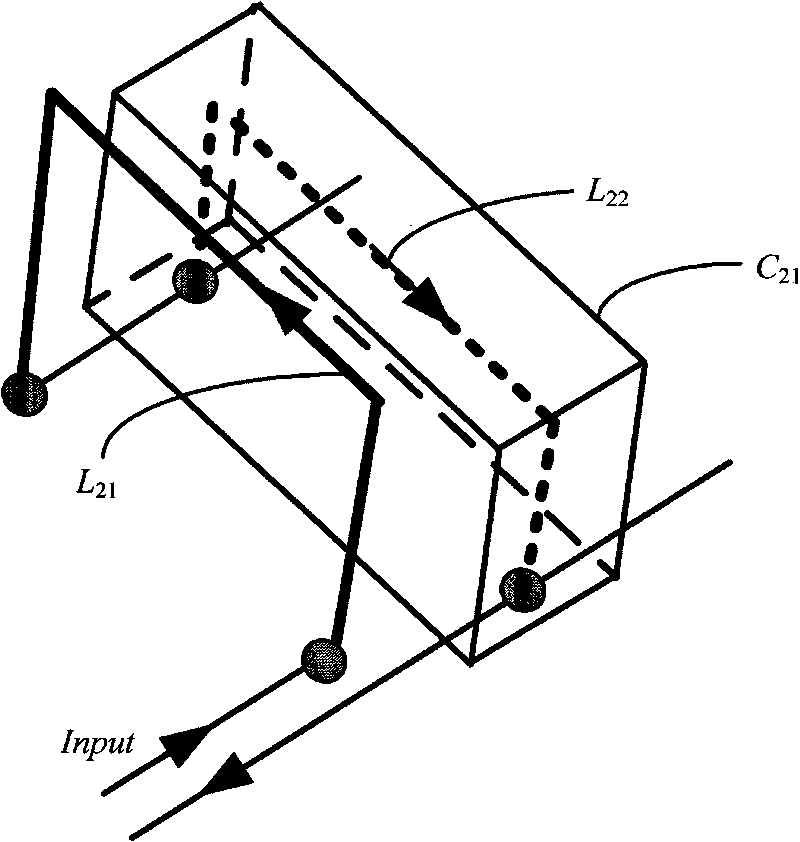

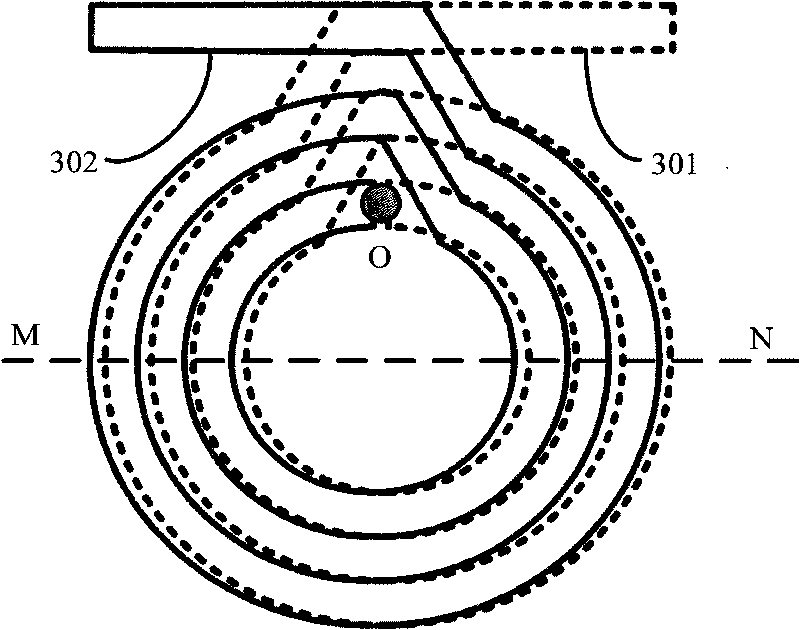

[0028] Such as Figure 4A In the example shown, the device for eliminating parasitic inductance of a capacitor provided by the present invention includes a PCB board 401 on which a capacitor 404 is mounted, two PCB winding coils 402 and 403, the coils are respectively on the upper and lower layers of the PCB, and It is forward coupling, that is, the end A of the upper coil 402 and the end C of the lower coil 403 are the same-named ends, and the B and C ends are connected by the via E. The pins G and H of the capacitor 404 are respectively mounted on the via holes E and F. According to the above connection, the parasitic inductance of the capacitor can be eliminated.

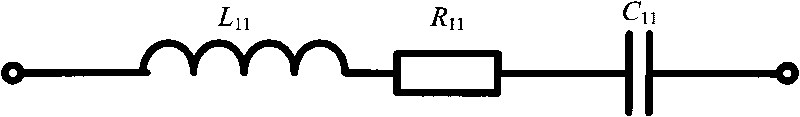

[0029] Figure 4B for Figure 4A The equivalent circuit diagram, the inductance values of the upper and lower PCB coils 402 and 403 are respectively L 41 And L 42 , M 41 Is mutual inductance, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com