Energy-saving type water group lost mould casting paint

A water-based, lost-foam technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve problems such as single selection of refractory materials, inability to peel off in pieces, and various defects on the surface of castings, so as to reduce the energy consumption of sand cleaning , Reduce the possibility of various defects on the surface of castings, and reduce the effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

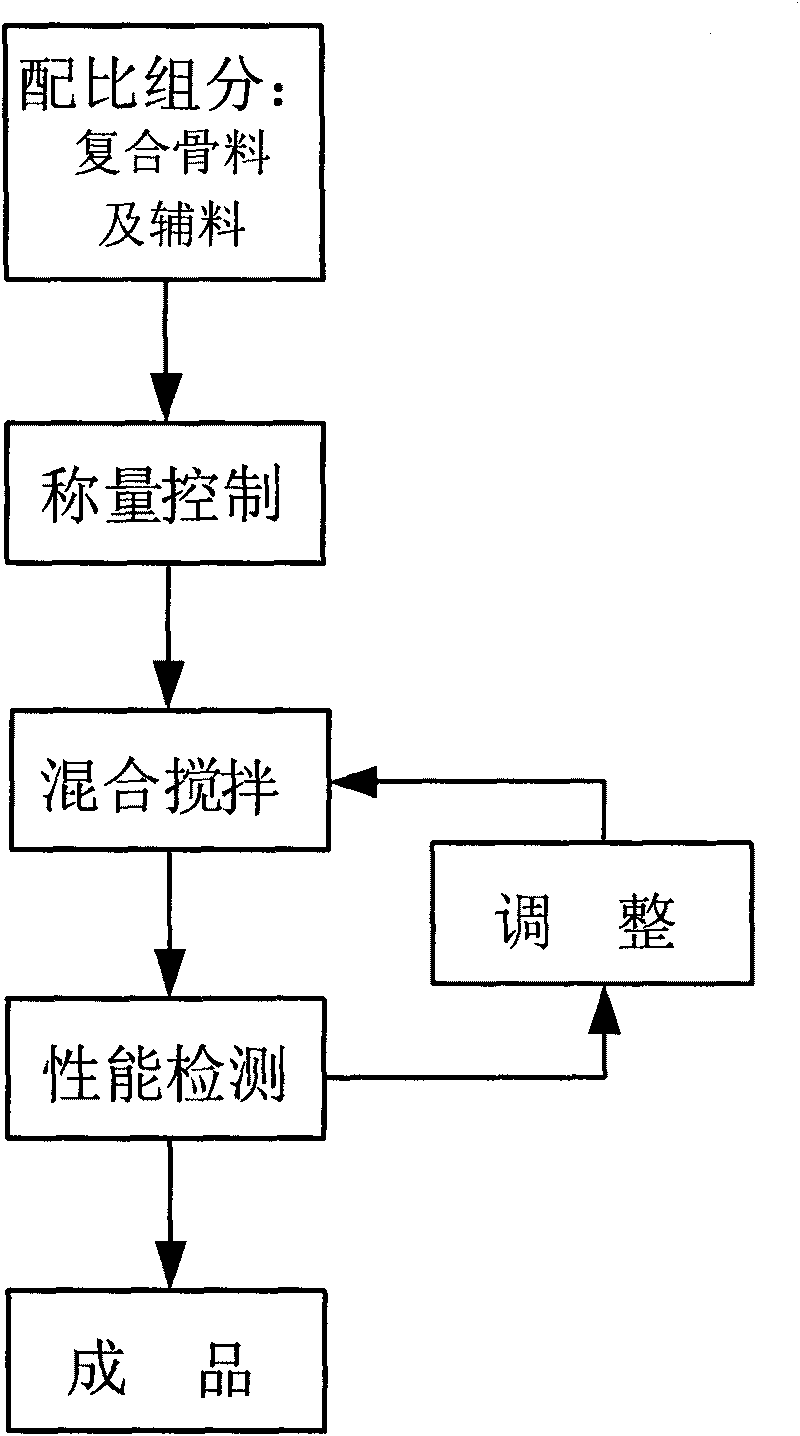

[0015] figure 1 The preparation process of the energy-saving foundry water-based lost foam coating of the present invention is shown.

[0016] The energy-saving casting water-based lost foam coating of the present invention is composed of refractory materials, binders, suspending agents, auxiliary agents and water,

[0017] The refractory material is a composite refractory material, including bauxite, zircon powder, and pyrophyllite, and its mixing ratio in parts by weight is: 20~40:60~80:5~10;

[0018] The weight percentage proportioning of described coating is:

[0019] 60-80% of composite refractory material, 0.5-3% of binder, 1-2% of suspending agent, 0.5-2% of auxiliary agent, and the rest is water.

[0020] 1. First prepare composite refractories according to the table below:

[0021] Example

Bauxite (kg)

Pyrophyllite (kg)

1

20

70

5

2

24

80

6

3

30

75

8

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com