Glass and metal vacuum brazing technique

A brazing process and a technology for metal workpieces, applied in the field of glass and metal vacuum brazing process, can solve the problem of difficulty in meeting the quality requirements of glass and metal sealing joints in solar collectors, low quality of welded joints, limited connection methods, etc. problems, to achieve the effect of low cost, few welding steps, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A glass and metal vacuum brazing process, the process includes the following steps:

[0025] 1) Treat glass and metal surfaces:

[0026] i. Sand blast the glass surface, then clean the surface with acetone, ethanol and water; put the metal workpiece in a hydrogen burning furnace for "hydrogen burning" purification treatment, and then polish the end surface with 1000# sandpaper and metallographic paper , After obtaining a smooth end face with a certain roughness, clean it with acetone, ethanol and water respectively. Finally, the glass and metal workpieces are dried in a drying oven for later use.

[0027] ii. Coating a uniform layer of copper on the surface of the glass workpiece.

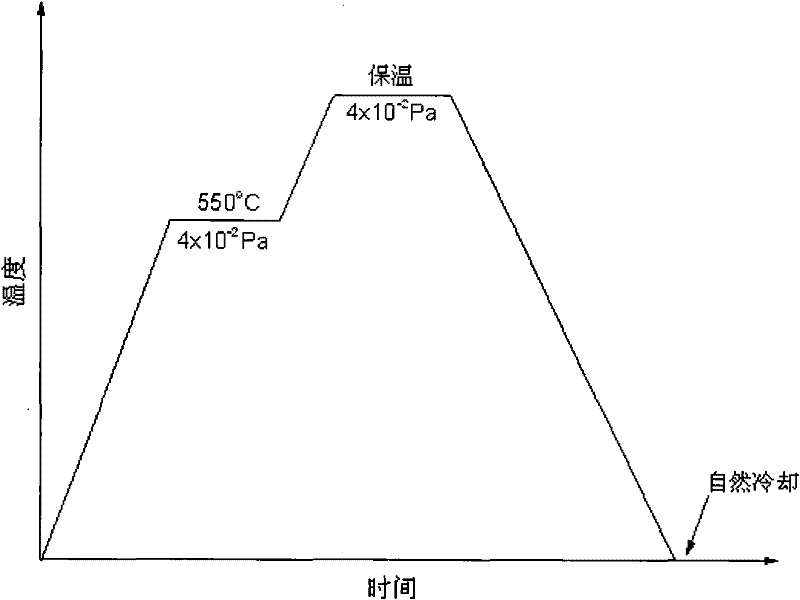

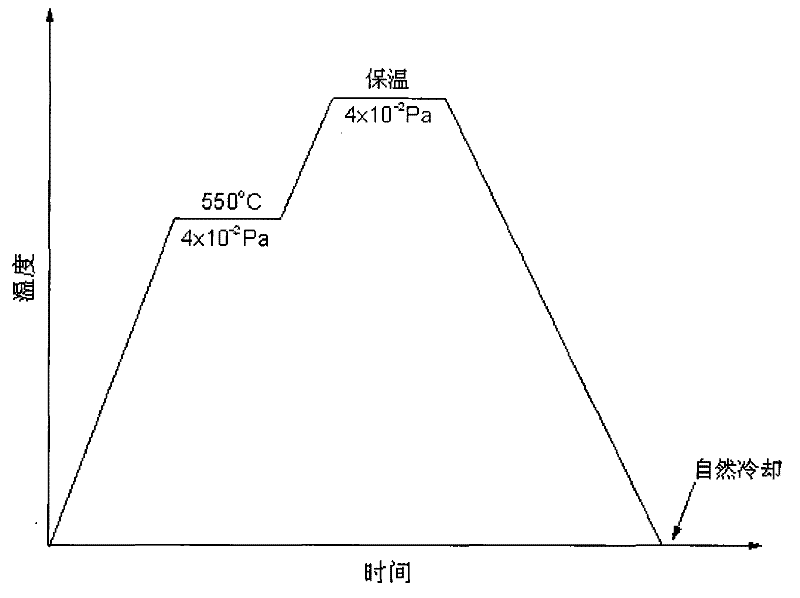

[0028] 2) Assemble the processed welded workpieces, then place them in a vacuum brazing furnace, evacuate and heat for vacuum brazing:

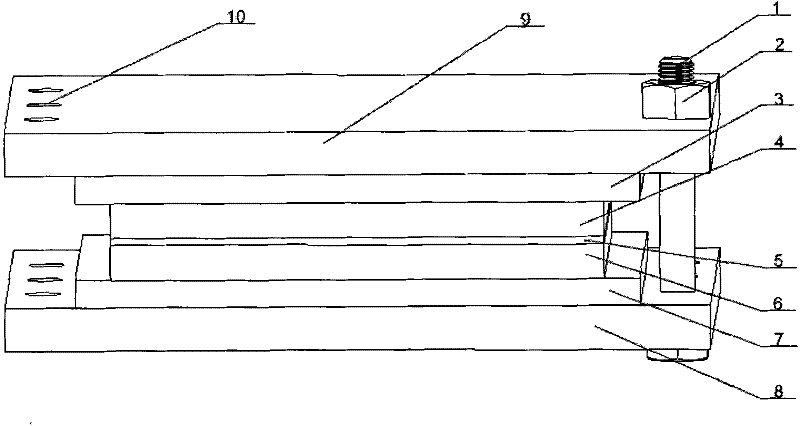

[0029] i. The solder 5 is preset in the welding interface between the glass 4 and the metal 6, taking into account the influence of the expansion and de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com