Production method of ficus carica raw juice wine

A production method and technology for figs, which are applied in the field of fig original juice wine production, can solve the problems of difficulty in achieving the aroma and taste of figs, and achieve the effects of rich varieties of colors, long aftertaste and mellow flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

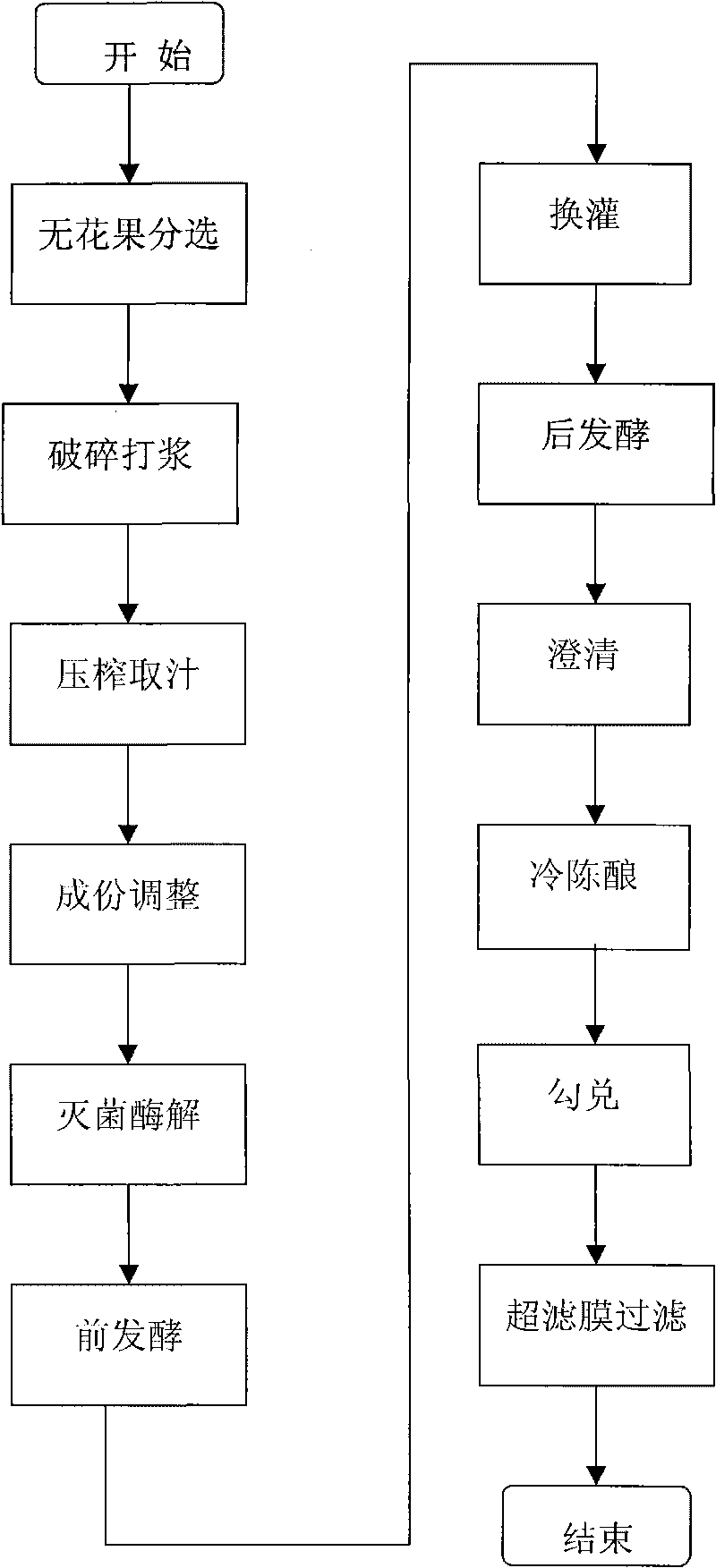

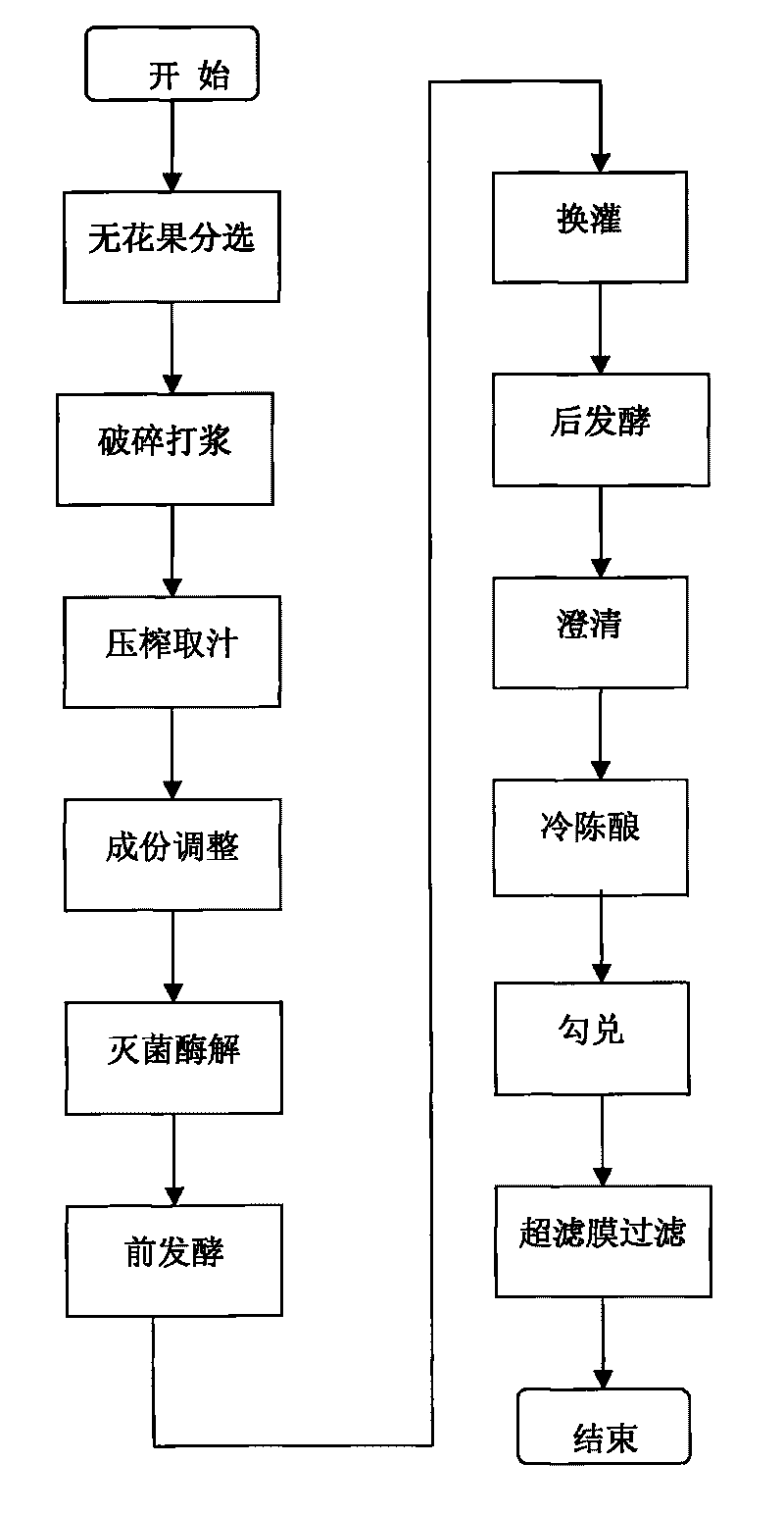

[0023] figure 1 It is a flowchart of the production method of fig original juice wine. Including the following steps:

[0024] Fig Sorting: Collect figs in sunny days, sort out mature fruits, remove green fruits, moldy and rotten fruits and other impurities, and rinse the sorted fruits with clean water.

[0025] Crushing and beating: Use a beater to crush the sorted figs, and add a certain amount of preservatives in time to prevent the fruit from being contaminated by bacteria.

[0026] Squeeze to get the juice: squeeze the juice from the crushed and beaten figs with a squeezer, and add 0.07% ascorbic acid in the squeezed juice.

[0027] Component adjustment: the fruit juice is analyzed, and the sugar content is adjusted to 150 g / liter, the addition of sodium metabisulfite is 75 mg / liter (measured with a sulfur dioxide meter) according to its composition, and the pH value is adjusted to 3.5 with tartaric acid.

[0028] Sterilization and enzymatic hydrolysis: heat the squeez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com