Construction method of conjoined mortar piling wall

A construction method and mortar technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of increased construction cost, uneven occlusion, high early strength, etc., and achieve reduced project cost, strong cutting ability, and low early strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The construction method of the conjoined mortar pile wall of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

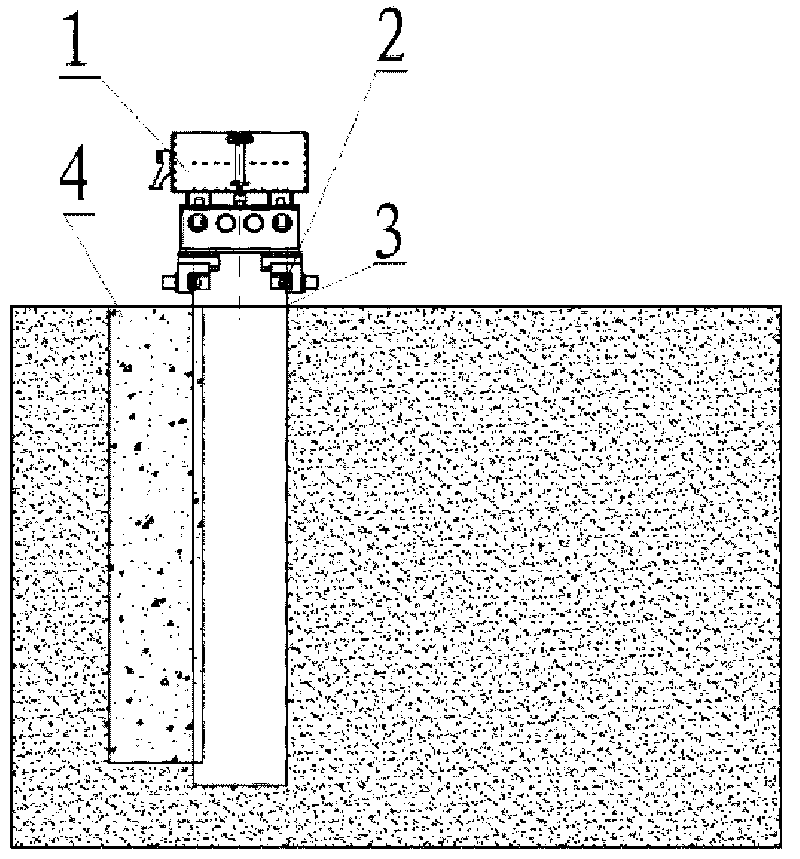

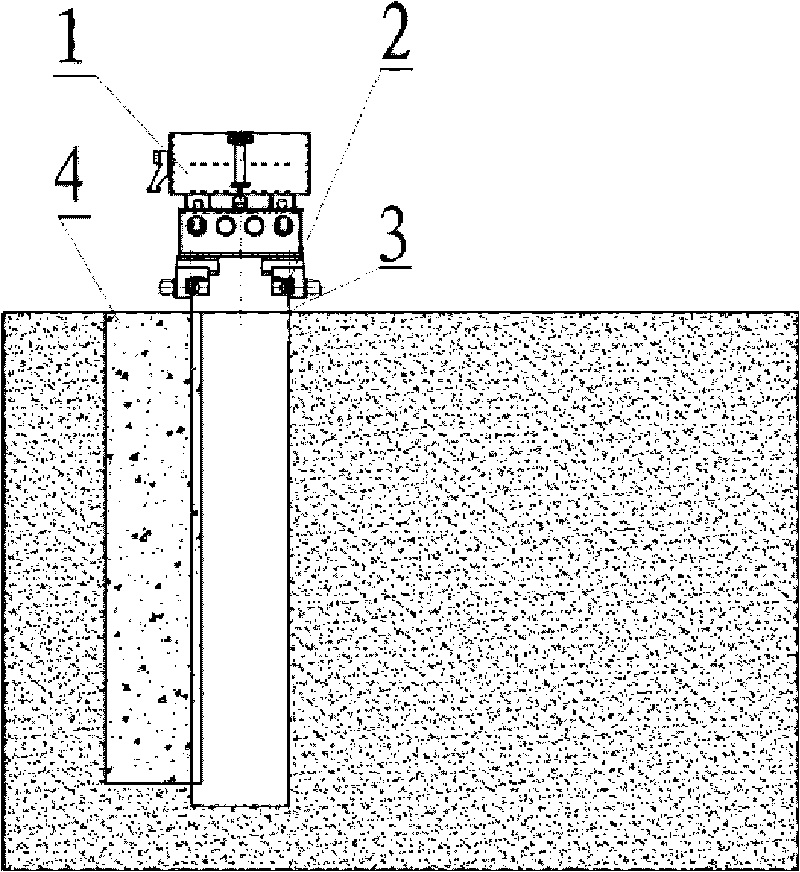

[0012] figure 1 The steel pipe holder 2 installed on the vibrating hammer head 1 of the vibrating soil-taking cast-in-situ pile machine shown in the figure clamps the steel casing 3 and sinks to the design elevation on the first pile position, soil is taken manually or mechanically, and the final hole is checked and accepted After passing the test, the sand, water and cement can be put into the mixer according to the construction ratio and stirred evenly to form a mixed mortar, and then the mortar is poured into the steel casing 3, and the steel casing 3 is pulled out by vibration to form the first mortar Pile 4, then move the pile driver to the second pile position, the second pile position is engaged with the first pile position, sink the steel casing 3 to the design posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com