Optical driving micro valve and driving method thereof

A light-driven, micro-valve technology, applied in sliding valves, valve details, diaphragm valves, etc., can solve the problems of high power consumption, high electric field voltage, and long response time, and achieve simple manufacturing steps, large transmission power, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below. It should be noted that the embodiments described here are for illustration only, and are not intended to limit the present invention.

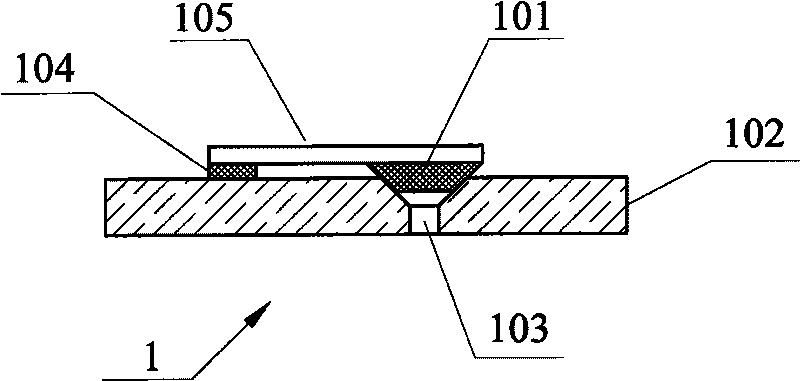

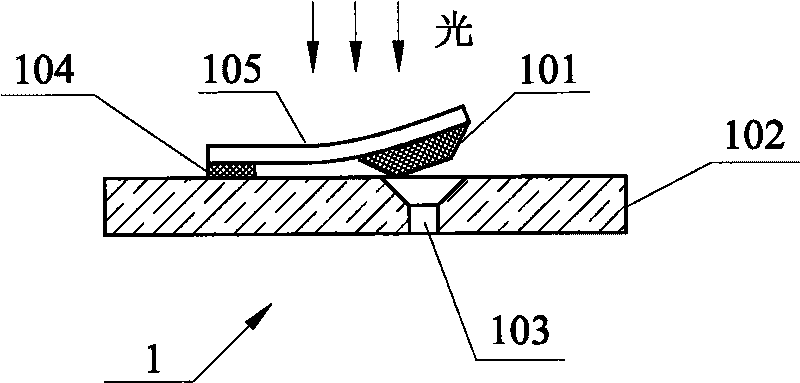

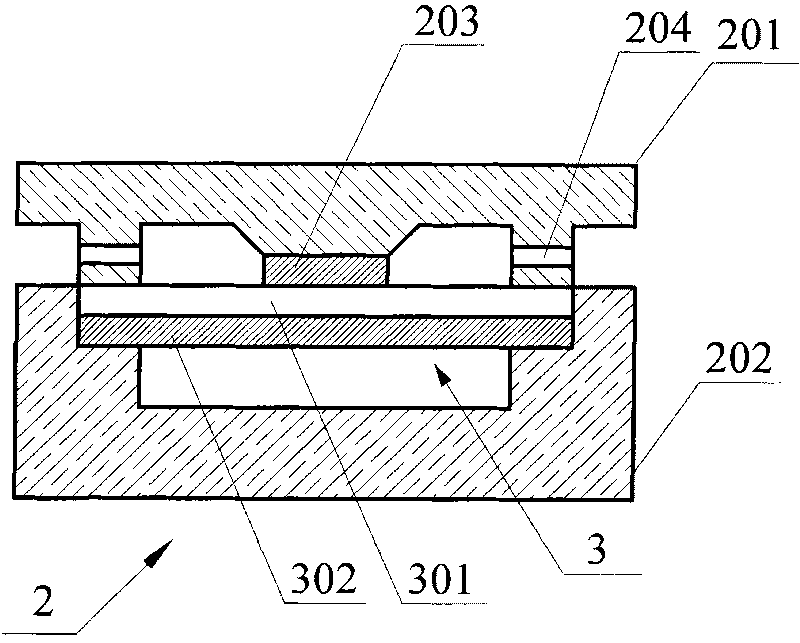

[0025] The light-driven microvalve in the present invention includes at least one deformable unit, and the unit includes a photodeformable material that is stretched and deformed under light. As shown in the figure, the microvalve has two structures, one is a cantilever beam structure 1 and the other is a valve membrane structure 2 .

[0026] The light-driven microvalve 1 with a cantilever beam structure is composed of a cantilever bracket 104 , a valve plug 101 and a cantilever beam 105 made of photodeformable material. One end of the cantilever beam 105 is fixedly connected to the cantilever bracket 104 by an adhesive, the other end is bonded to the valve plug 101 , and the rest is suspended in the air. The mating surface of the valve plug 101 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com