High-precision quick response pilot valve

A fast-response, high-precision technology, applied in safety valves, balance valves, valve devices, etc., can solve the problem of not meeting the requirements of use, and achieve the effect of improving the working conditions of throttling and variable damping, easy production, and high applicable pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

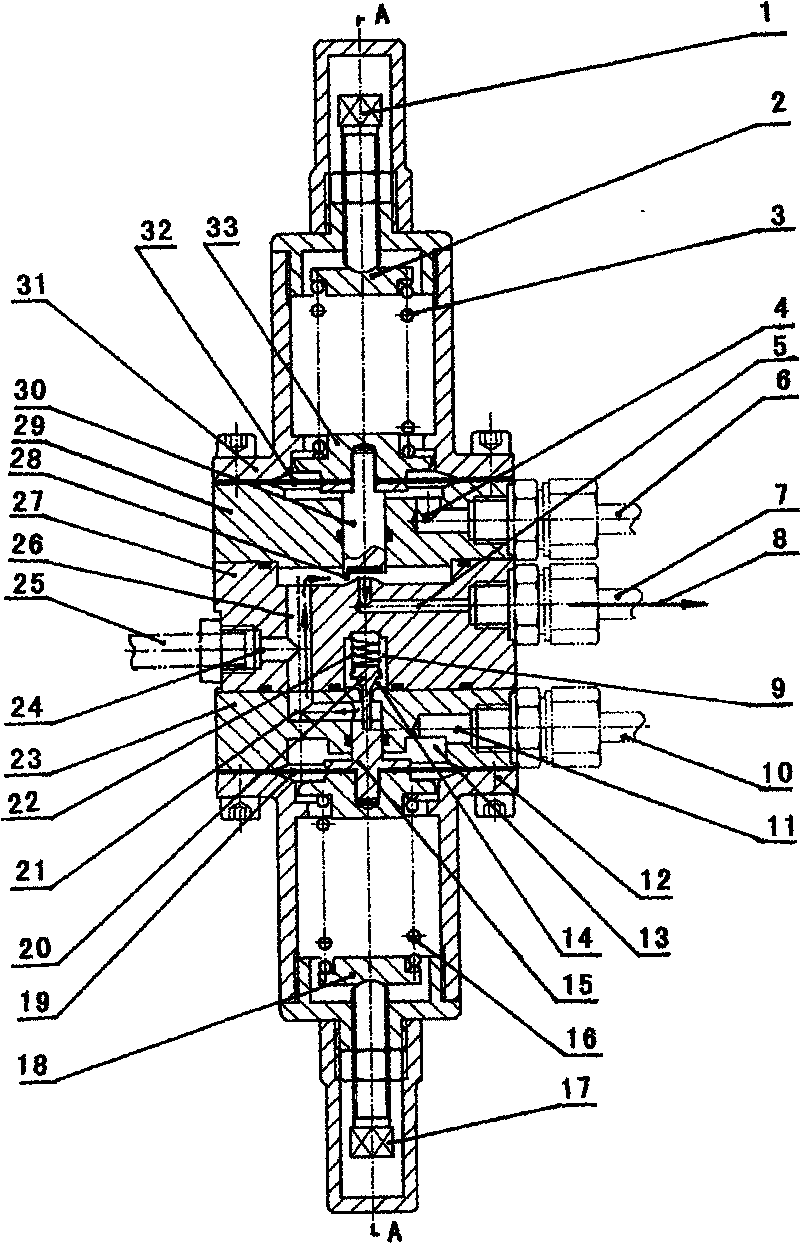

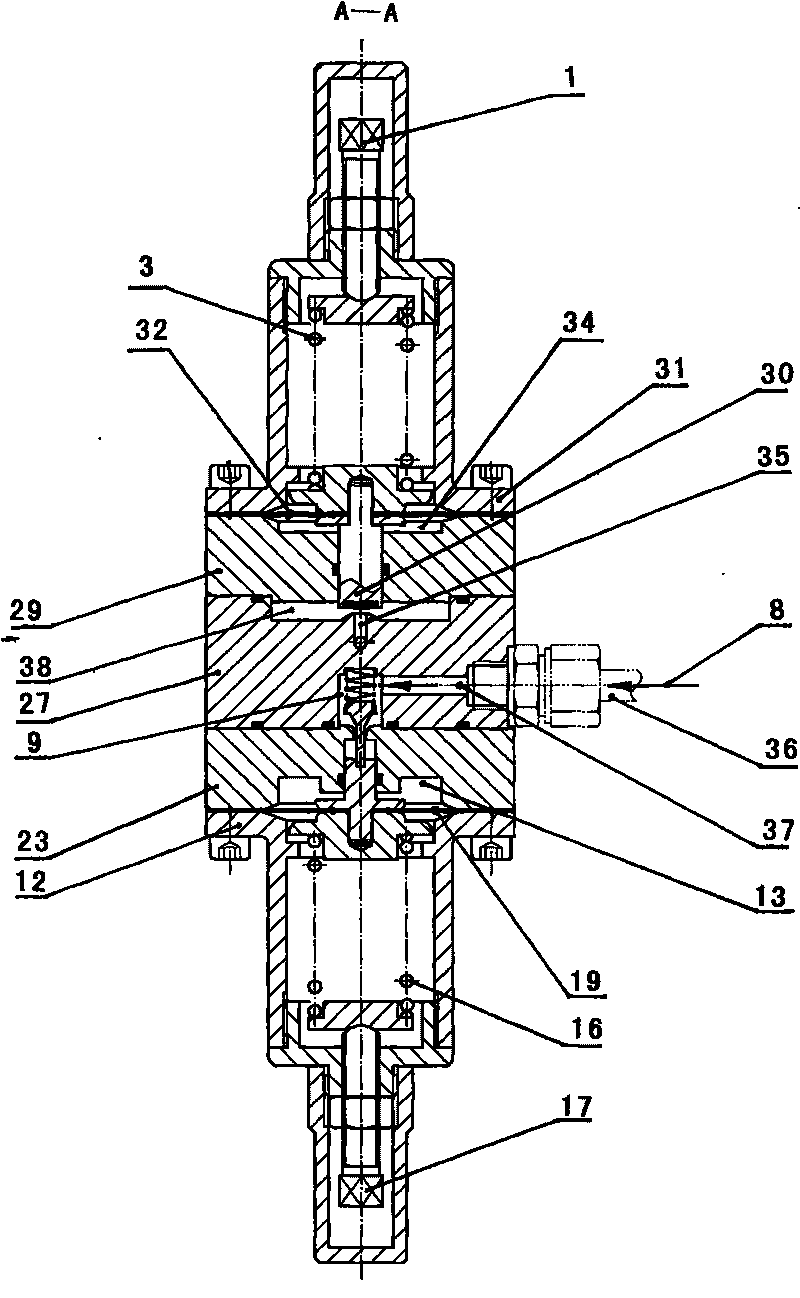

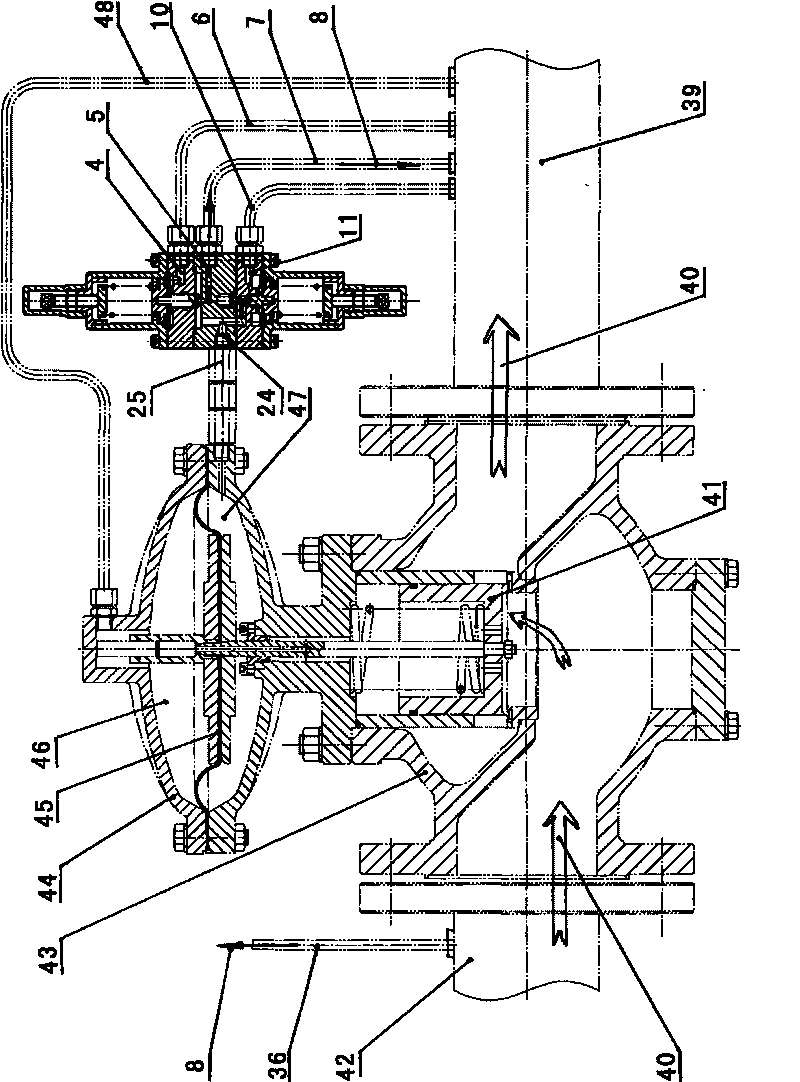

[0021]A high-precision quick-response pilot valve, which is mainly composed of a valve body 27, a pressure-regulating valve port 23, a pressure-regulating diaphragm assembly 19, a pressure-regulating valve cover 12, a pressure-regulating spring 16, a pressure-regulating spring seat 18, and a pressure-regulating screw rod 17 , a damping valve port 29, a damping diaphragm assembly 32, a damping valve cover 31, a damping spring 3, a damping spring seat 2, and a damping screw 1. The valve body 27 is provided with a valve cavity 9 communicating with the front pressure airflow introduction interface 37, The pressure regulating air passage 26 communicated with the pressure regulating sensing interface 24, the spring 22 assembled in the valve chamber 9, the pressure regulating valve core 20 and the pressure regulating valve port 23 constitute the front pressure regulating orifice 14, the said pressure regulating The valve core 20 is fixedly connected to the connecting screw 15 of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com