Method for measuring microelement in sodium aluminate solution

A technology of medium and trace elements and sodium aluminate, applied in the direction of material excitation analysis, thermal excitation analysis, etc., can solve the problems of cumbersome operation, long analysis period, high salt in industrial sodium aluminate solution, etc., to achieve reliable analysis data and improve analysis speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

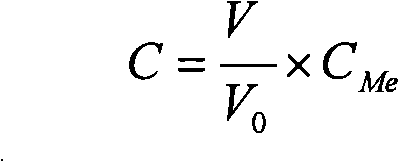

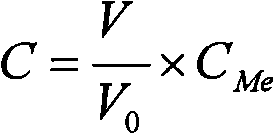

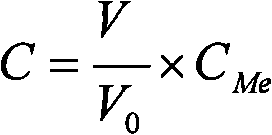

Method used

Image

Examples

preparation example Construction

[0032] 4.1 Preparation of analytical solution

[0033] Pipette 2.00 mL of the obtained sample solution (3) into a 100 mL volumetric flask while hot, add 6 mL of hydrochloric acid (1.1) to acidify until the precipitate is completely dissolved, add 10 mL of hydrochloric acid to the sample that has not completely dissolved the precipitate and heat it in a water bath until it is completely dissolved, dilute to the mark and mix well.

[0034] 4.2 Measurement times

[0035] Two determinations were carried out independently, and the average value was taken.

[0036] 4.3 Blank test

[0037] Do a blank test with the sample.

[0038] 4.4 Draw the working curve:

[0039] Pipette 0, 5.00mL, 10.00mL, 15.00mL, 50.00mL standard solutions into a set of 100mL volumetric flasks, respectively add 1.00mL aluminum matrix solution (1.4), dilute to the mark with water, and mix well.

[0040] 4.5 Measurements.

[0041] According to the different detection equipment used, select the best working...

Embodiment 1

[0060] (1) Pipette 2.00 mL of the obtained sodium aluminate solution into a 100 mL volumetric flask while it is hot, add 6 mL of hydrochloric acid (1+1) to acidify until the precipitate is completely dissolved, and add 10 mL of hydrochloric acid (1+1) to the sample that is not completely dissolved. ) and heated in a water bath until completely dissolved, diluted to the mark, and mixed.

[0061] (2) Draw the working curve: pipette 0, 5.00mL, 10.00mL, 15.00mL, 50.00mL standard solutions into a set of 100mL volumetric flasks respectively, add 1.00mL aluminum matrix solution (1.4), dilute to the mark with water, mix uniform.

[0062] (3) Sample measurement: introduce the standard series solution and the sample solution into the plasma respectively, and measure the line intensity of each element in the working curve solution and each element in the sample solution from low to high under the optimal working conditions of the selected instrument Analyze the strength of the line.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com