Method for manufacturing double-sided hollow flexible circuit board

A technology of flexible circuit boards and manufacturing methods, which is applied in the fields of printed circuit manufacturing, printed circuits, electrical components, etc., and can solve the problem of poor coincidence of the upper and lower copper foils at the hollowed-out terminal parts, the thickness of the hollowed-out parts of the terminals cannot be made very thin, and the hollowed-out terminals Poor part accuracy and other problems, to achieve a high pass rate, suitable for mass production, and ensure the effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

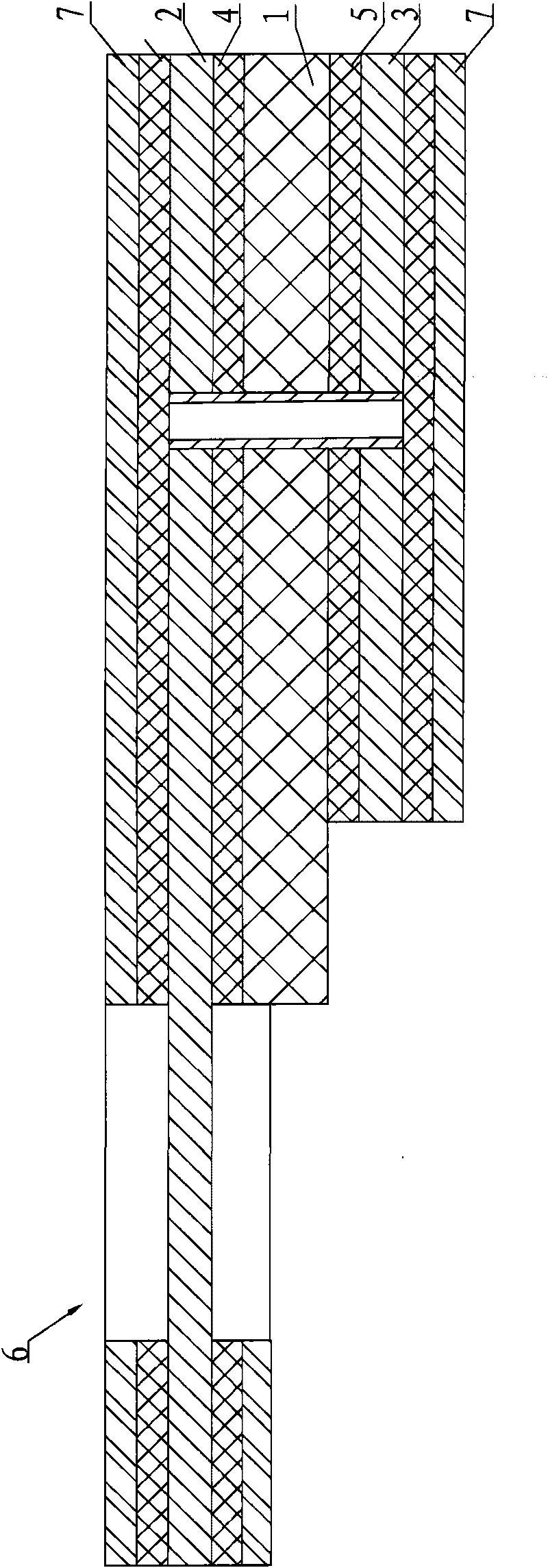

[0022] According to the manufacturing method of the double-sided hollow flexible circuit board of this embodiment, the following steps are sequentially included:

[0023] (1), take the first copper foil (18 microns thick), the first bonding board (semi-cured epoxy resin material, model MS13A, Shenzhen Shengming Electronic Materials Co., Ltd.), insulating material board (polyimide substrate ), the second bonding board, and the second copper foil (18 microns thick), the predetermined areas of the first bonding board, insulating material board and the second bonding board are punched out with a punching die to form the opening of the hollowed out part;

[0024] (2) Align the first copper foil, the first bonding board, the insulating material board, the second bonding board, and the second copper foil with the positioning holes one by one for fixing, and then place them in a vacuum laminator at a temperature of 100°C 1. The pressure is 10 kg / cm2 and the holding time is 30 minutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com