Method of in situ growth of nano titanium dioxide protective layer on wood surface

A nano-titanium dioxide and wood surface technology, applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of complex process, high cost, waste of raw materials, etc., and achieve simple process, low reaction cost and high utilization rate of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

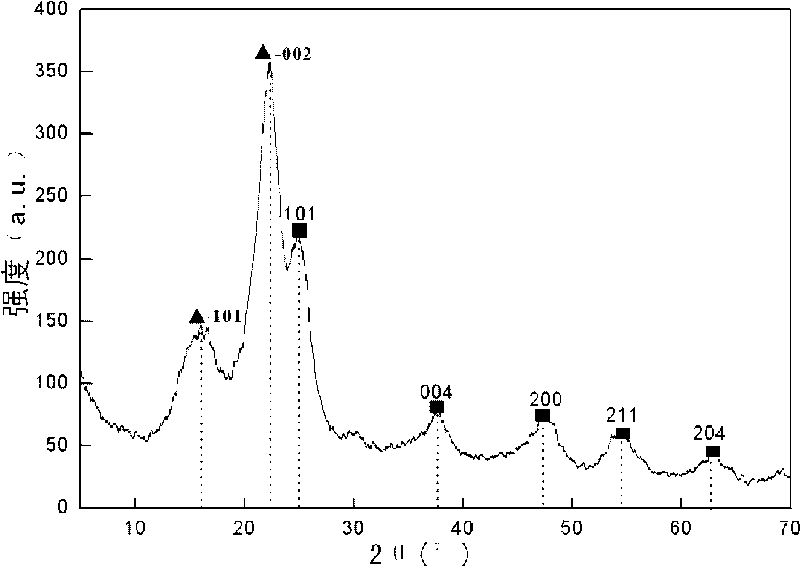

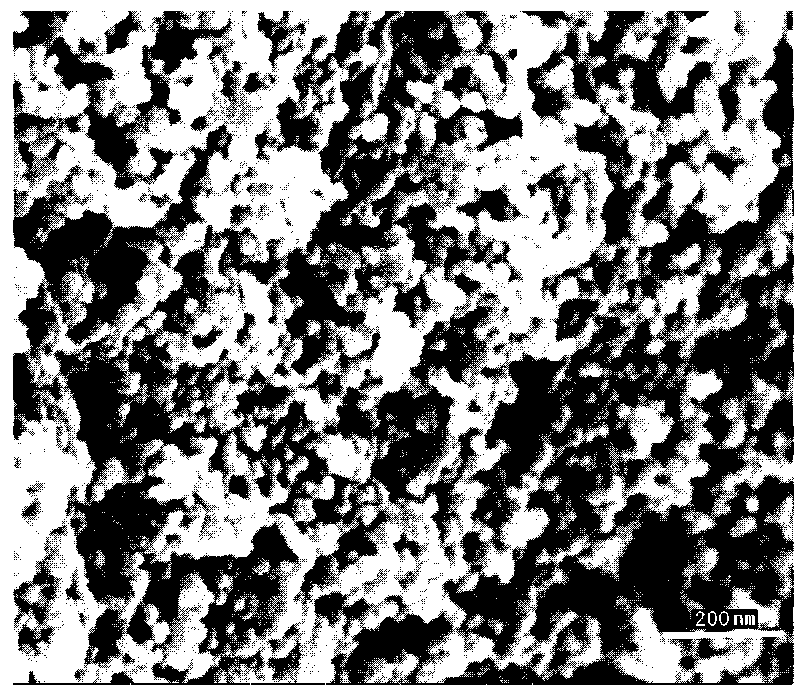

[0012] Specific Embodiment 1: In this embodiment, the method for growing a nano-titanium dioxide protective layer in situ on the wood surface is achieved through the following steps: 1. After cleaning or polishing the wood surface, immerse it in 0.01-5mol / L titanium salt alcohol solution , then seal the reactor, and then cool to room temperature after hydrothermal reaction at 60-200°C for 3-8 hours; 2. Prepare 3.0×10 -4 ~20×10 -4 mol / L sodium dodecylsulfonate (SDS) solution, then adjust the pH value to 8-10, then add it into the reactor, then seal the reactor, and react at 70°C for 4-8h, in which dodecane The volume ratio of sodium sulfonate (SDS) solution to titanium salt alcohol solution is 1:1; 3. After drying the wood treated in step 2 for 10 to 15 hours at 40 to 50°C, the in situ growth nanometer on the surface is obtained. Titanium dioxide protective layer of wood.

[0013] The preparation of the titanium salt alcohol solution in this embodiment is an existing conventi...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment is different from Embodiment 1 in that the wood in step 1 is poplar, birch, Chinese fir or balsa. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the titanium salt in step 1 is tetrabutyl titanate, sulfuric acid phthalein or titanium tetrachloride. The other steps and parameters are the same as the specific way 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com