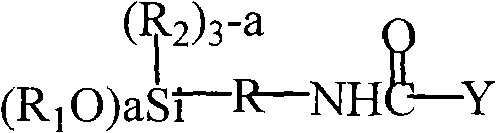

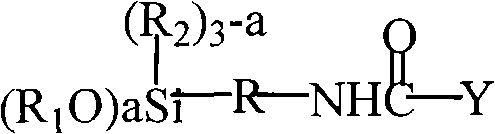

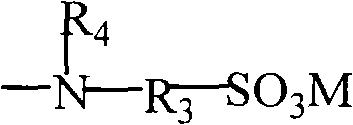

Water-soluble system structure based on isocyanate-yl alkyl alkoxy silane and preparation method thereof

A technology of ester-based alkylalkoxysilane and ester-based alkoxysilane, which is applied in the field of isocyanate-based alkylalkoxysilane water-soluble system structure and its preparation, and can solve the storage stability and service life of water-based systems Limited, unsuitable silane, limited water solubility of water-based silane system, etc., to achieve good hydrophobic effect, good stability, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Take 50g of dehydrated polyoxyethylene ether glycol with a molecular weight of 500, and 50g of solvent toluene, and add it to a four-necked flask with a reflux dripping device, a stirring device, a thermometer and an inert gas inlet to account for the total amount. 0.5% dibutyltin dilaurate was used as a catalyst, and argon gas was introduced, and the temperature was raised to 80°C. Then, 49.4 g of γ-isocyanatopropyltriethoxysilane was slowly added dropwise. After the dropping was completed, the reaction was kept warm, and the isocyanate content was measured every 30 min, and the reaction was stopped when it reached 0. The resulting mixture is distilled under reduced pressure to remove the solvent to obtain a water-soluble silane product. The product is light yellow transparent liquid.

Embodiment 2

[0054] Take 100 g of dehydrated single-ended hydroxy polyoxyethylene ether with a molecular weight of 1000, and 50 g of solvent toluene, and add it to a four-necked flask with a reflux dripping device, a stirring device, a thermometer and an inert gas inlet to account for the total amount. 0.5% dibutyltin dilaurate was used as a catalyst, and argon gas was introduced, and the temperature was raised to 80°C. Then, 24.7 g of γ-isocyanatopropyltriethoxysilane was slowly added dropwise. After the dropwise addition, the reaction was kept warm, and the isocyanate content was measured every 30 min, and the reaction was stopped when it reached 0. The resulting mixture is distilled under reduced pressure to remove the solvent to obtain a water-soluble silane product. The product is light yellow transparent liquid.

Embodiment 3

[0056] Get 100g of polyoxyethylene ether glycol with a molecular weight of 2000 after dehydration treatment, 50g of solvent toluene and ethyl acetate mixture, add it to a four-necked flask with a reflux dripping device, a stirring device, a thermometer and an inert gas inlet , 0.7% of the total amount of stannous octoate was used as a catalyst, argon gas was introduced, and the temperature was raised to 80°C. Then, 20.5 g of γ-isocyanatopropyltrimethoxysilane was slowly added dropwise. After the dropping was completed, the reaction was kept warm, and the isocyanate content was measured every 30 min, and the reaction was stopped when it reached 0. The resulting mixture is distilled under reduced pressure to remove the solvent to obtain a water-soluble silane product. The product is light yellow transparent liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com