Fire and heat resisting self-lubricating polycarbonate composite with nice appearance and preparation method thereof

A technology of polycarbonate and polycarbonate resin, which is applied in the field of good-appearance flame-retardant, heat-resistant, self-lubricating polycarbonate compositions and their preparation fields to achieve the effects of reducing costs, improving surface appearance and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

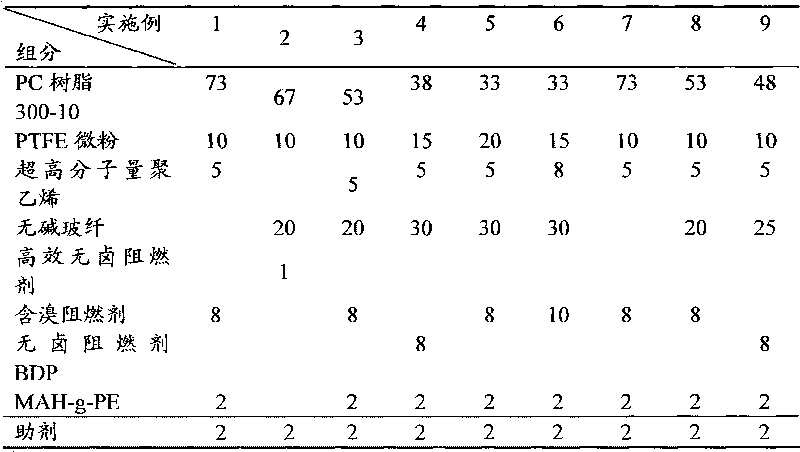

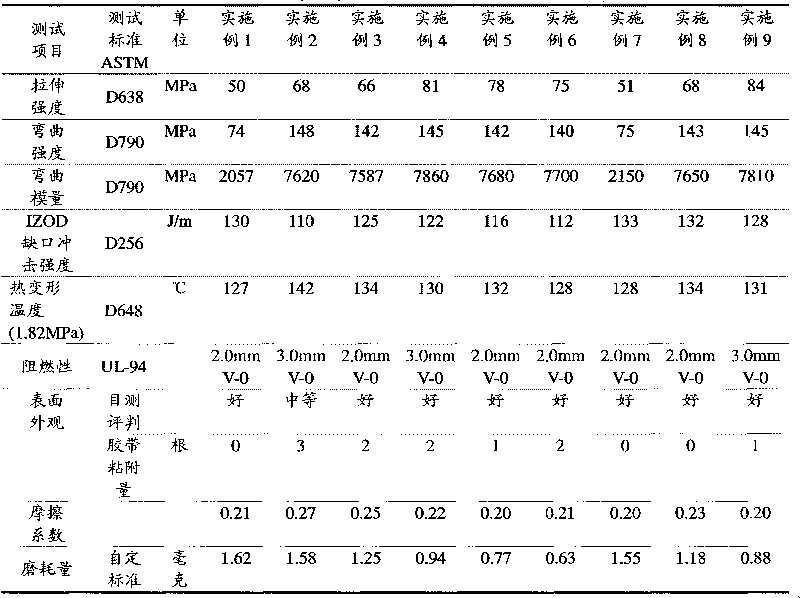

Embodiment 1-6

[0027] Examples 1-6: Prepared by one-step method of conventional mixing extrusion granulation.

[0028] Example 7-9 series: prepared by a two-step method, the specific steps are as follows:

[0029] First, mix polytetrafluoroethylene micropowder, ultra-high molecular weight polyethylene, maleic anhydride grafted polyethylene, flame retardant, auxiliary agent and a certain amount of polycarbonate resin according to the distribution ratio of each formula component in Example 7-9 of Table 1. After mixing in the high mixer, extrude and granulate at 230-260°C to make one-step material, then mix the one-step material and the remaining polycarbonate resin evenly in the high mixer, or place them in two high-precision metering In the feeding scale, the feeding is automatically controlled in proportion, and the composition pellets are obtained by extruding and granulating for the second time in the twin-screw extruder, while the glass fiber is fed in proportion by side feeding, and can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com