Organic waste dry-type anaerobic fermentation device and technology

A dry anaerobic fermentation, organic waste technology, applied in fermentation, organic fertilizer, waste fuel, etc., can solve the problems of large facilities, poor fluidity, unfavorable engineering, large-scale marketization, etc., and achieve scientific process and equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

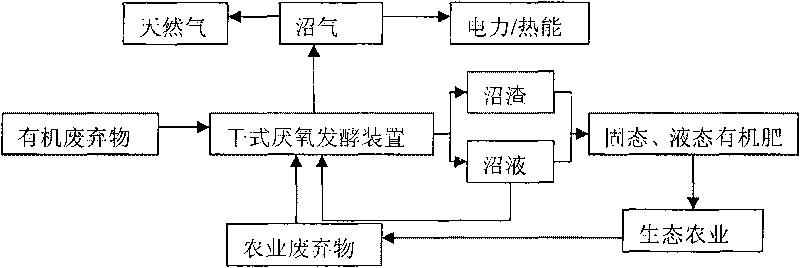

[0038] The example of the present invention provides a process and device for dry anaerobic fermentation treatment of organic waste. The invention relates to the operation method and device of plug-flow horizontal fermentation. The process is to put organic waste into a special anaerobic fermentation device, and carry out continuous stirring fermentation under the condition that the optimum temperature of 55-60 ° C is always maintained. After 15-30 days, high-concentration high-efficiency biogas and high-efficiency organic fertilizer rich in beneficial biological bacteria will be generated. Biogas can be converted into electricity and heat. Biogas can also be upgraded to natural gas standards, used as fuel for vehicles or transported to natural gas networks. Organic fertilizers include liquid organic fertilizers and solid organic fertilizers, which can be used to develop ecological agriculture.

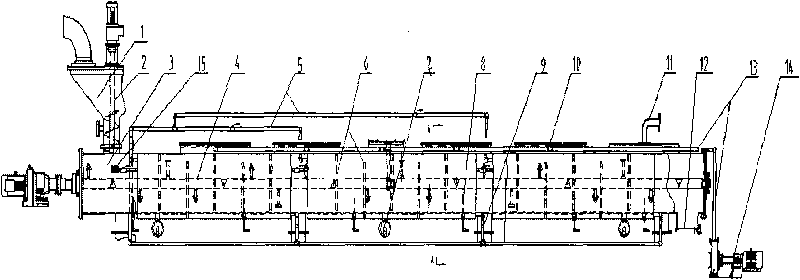

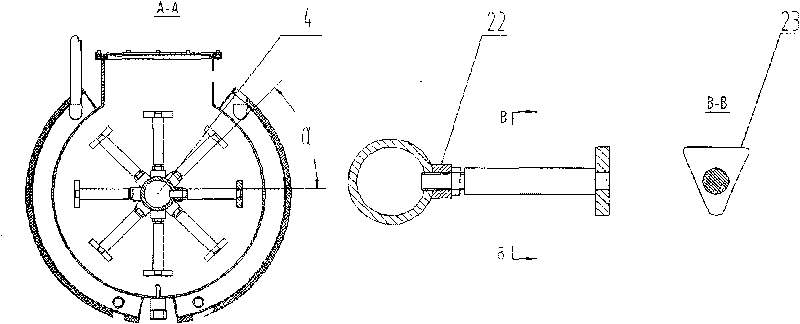

[0039] The plug flow horizontal fermentation device is a thermal insulation dry a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com