Device and process for preparing organic fertilizer by aerobic fermentation of sludge through high-pressure thermal cracking

A technology of aerobic fermentation and production process, applied in organic fertilizer equipment, preparation of organic fertilizer, organic fertilizer and other directions, can solve the problems of reducing the amount of contact between materials and oxygen, reducing fermentation effect, poor fermentation effect, etc. The effect of stacking thickness, speeding up fermentation and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

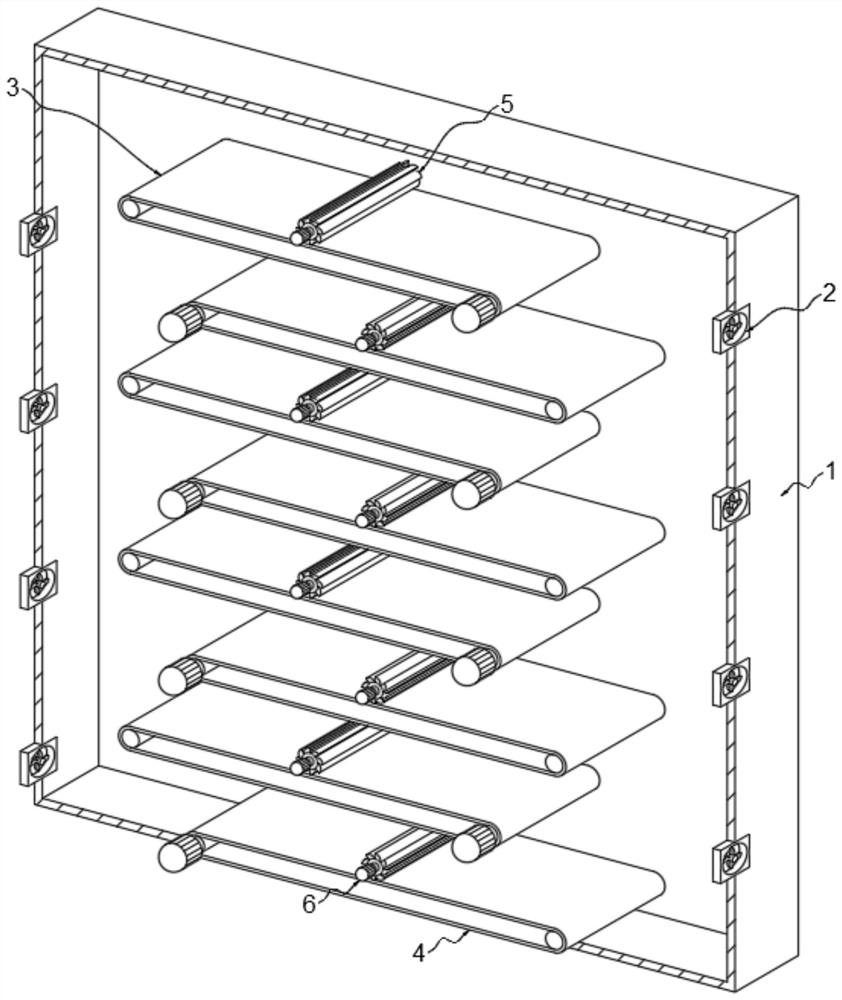

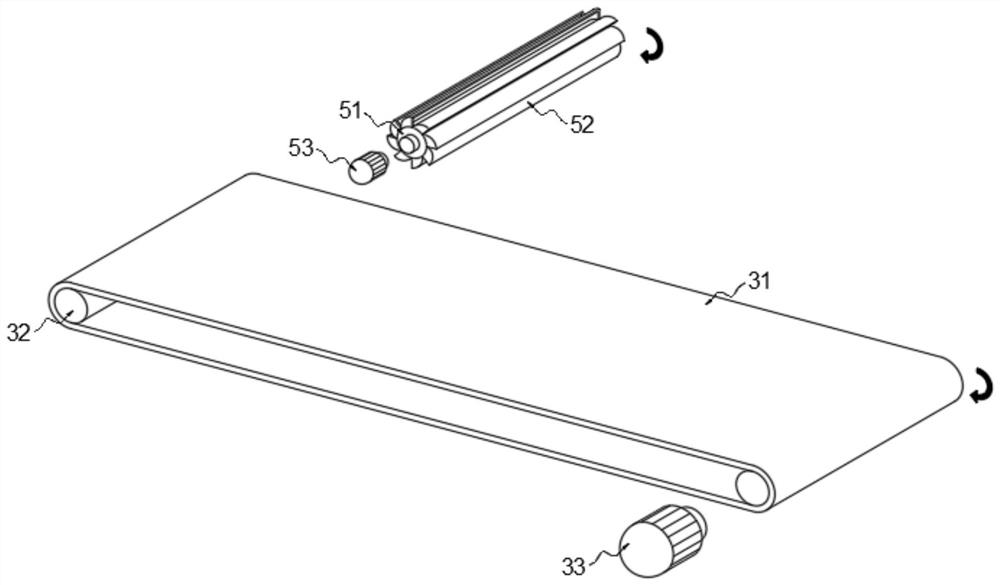

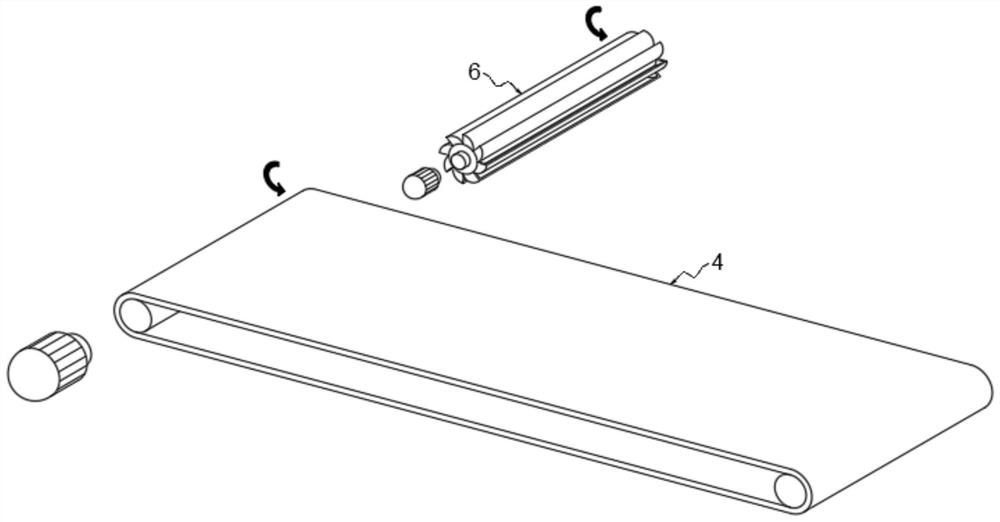

[0046] Such as Figure 1-3 As shown, the purpose of this embodiment is to provide a high-pressure pyrolysis sludge aerobic fermentation organic fertilizer production equipment, including a fermentation tank 1, and several high-pressure blowers 2 are arranged on the left and right side walls of the fermentation tank 1. A number of right conveyor belts 3 and left conveyor belts 4 are staggered from top to bottom. The right conveyor belt 3 includes a wide-surface belt 31, and the left and right ends of the wide-surface belt 31 are rotatably connected with transmission rollers 32, wherein the transmission rollers 32 near the right end The roller 32 is connected with a transmission motor 33 through a reducer, and a rightward stirring device 5 is provided in the middle of the top surface of the rightward conveyor belt 3. The rightward stirring device 5 includes a rotating roller 51, and the outer wall of the rotating roller 51 rotates in a clockwise direction. Regular welding is fix...

Embodiment 2

[0048] Such as Figure 1-3 As shown, on the basis of the equipment embodiment 1, the purpose of this embodiment is to provide a high-pressure pyrolysis sludge aerobic fermentation organic fertilizer production equipment, including a fermentation tank 1, and the left and right side walls of the fermentation tank 1 are equipped with A number of high-pressure blowers 2, a number of right-hand conveyor belts 3 and left-hand conveyor belts 4 are staggered from top to bottom in the fermentation box 1, and the right-hand conveyor belt 3 includes a wide-surface belt 31, and the left and right ends of the wide-surface belt 31 are rotated and connected. Conveying roller 32, wherein on the conveying roller 32 close to the right end, be connected with conveying motor 33 by speed reducer, be provided with rightward stirring device 5 in the middle of the top surface of rightward conveyor belt 3, rightward stirring device 5 comprises rotating roller 51, rotates On the outer wall of the rolle...

Embodiment 3

[0051] Such as Figure 1-3As shown, on the basis of the equipment embodiment 2, the purpose of this embodiment is to provide a high-pressure pyrolysis sludge aerobic fermentation organic fertilizer production equipment, including a fermentation tank 1, and the left and right side walls of the fermentation tank 1 are equipped with A number of high-pressure blowers 2, a number of right-hand conveyor belts 3 and left-hand conveyor belts 4 are staggered from top to bottom in the fermentation box 1, and the right-hand conveyor belt 3 includes a wide-surface belt 31, and the left and right ends of the wide-surface belt 31 are rotated and connected. Conveying roller 32, wherein on the conveying roller 32 close to the right end, be connected with conveying motor 33 by speed reducer, be provided with rightward stirring device 5 in the middle of the top surface of rightward conveyor belt 3, rightward stirring device 5 comprises rotating roller 51, rotates On the outer wall of the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com