Method for cycle power generation by carrying out wet decomposition pretreatment, dry distillation and gasification on domestic garbage

A domestic garbage and cycle power generation technology, which is applied in the direction of machines/engines, steam engine devices, mechanical equipment, etc., can solve the problems of complex operation, expensive cost, waste of resources, etc., and achieve a high degree of industrialization, low operating costs, and an small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

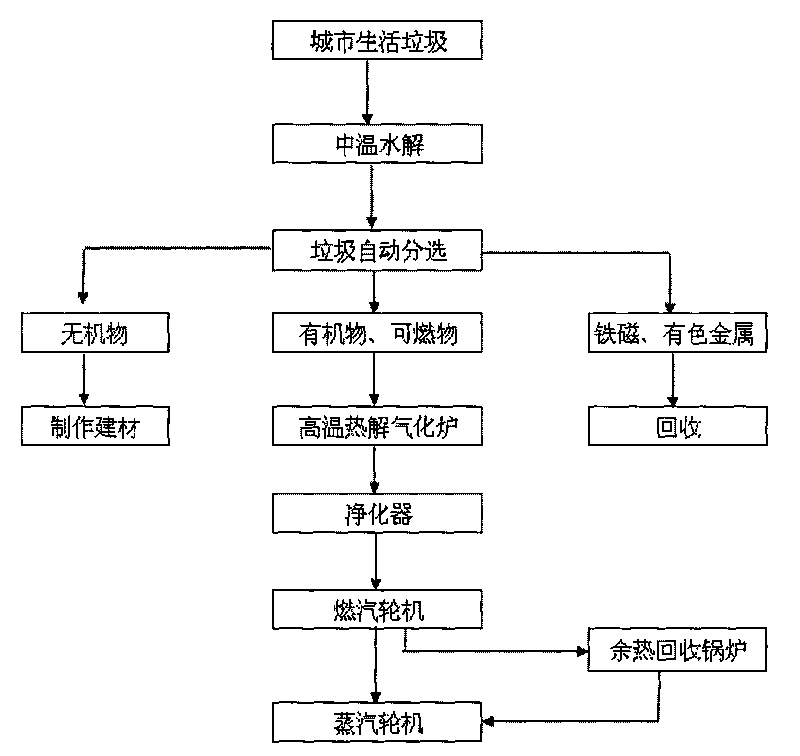

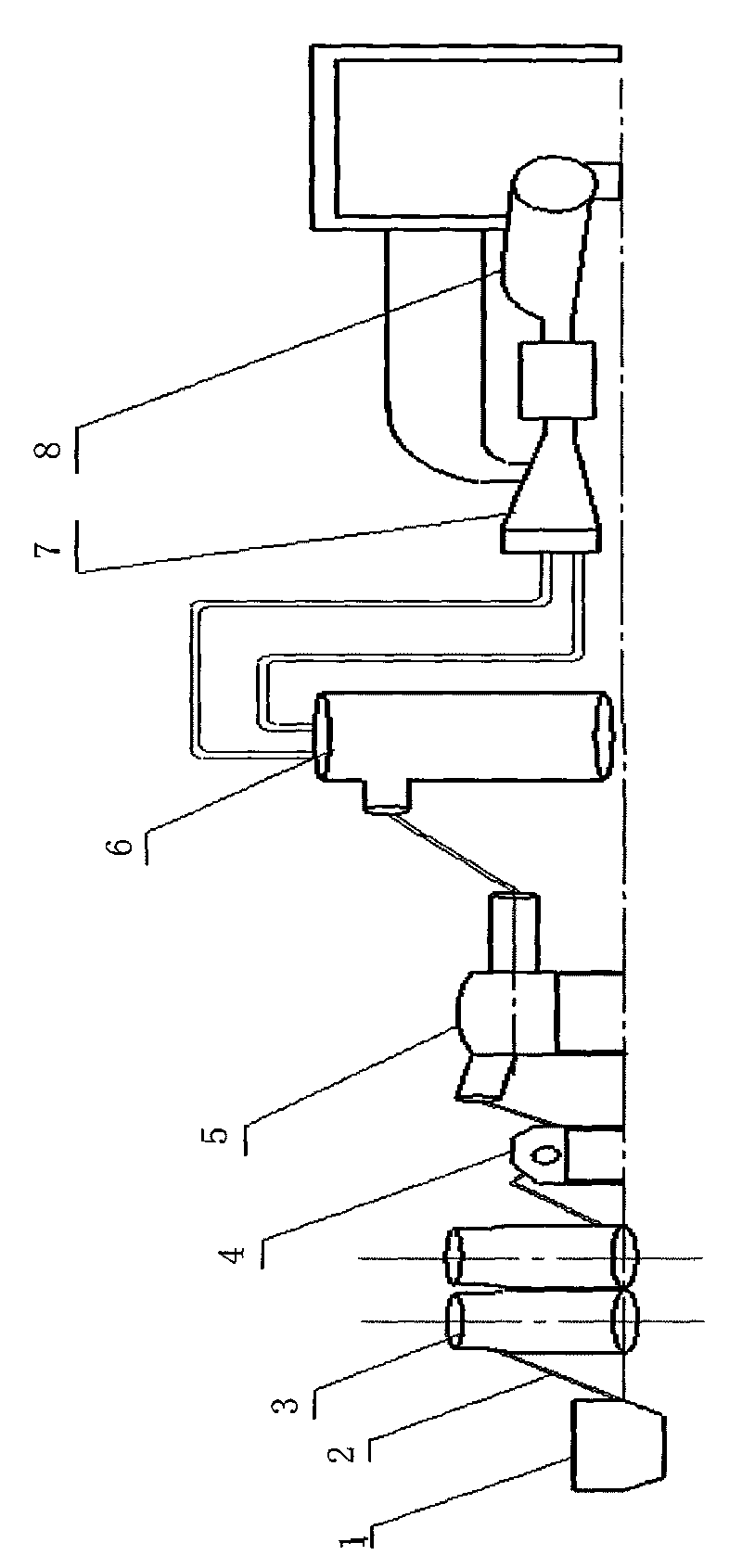

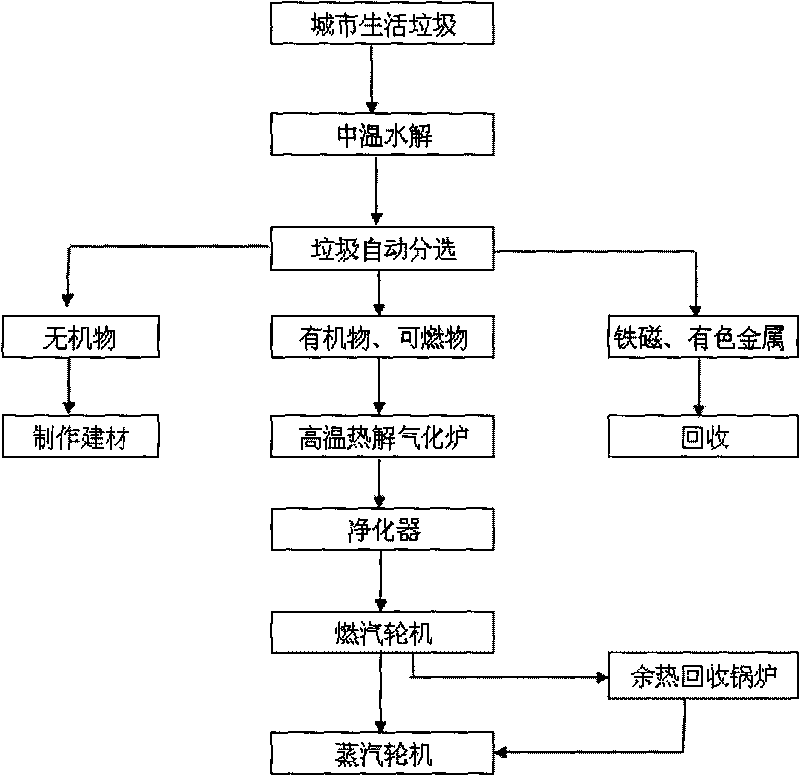

[0025] like figure 1 and figure 2 As shown, this embodiment mainly includes the following process steps:

[0026] 1. Medium temperature and high pressure hydrolysis treatment

[0027] First, the garbage is sent from the garbage storage bin 1 to a high-pressure container bin 3 through the conveyor belt 2, steam is introduced into the high-pressure container bin 3, and the garbage is heated under the conditions of 200~260℃ and 0.3~0.8Mpa pressure. Pressurize for 2 to 4 hours, perform high temperature sterilization, deodorization, disinfection, hydrolysis and dechlorination, debenzene, dehydration and weight reduction on the garbage, and then reduce the pressure to 0.1 to 0.2MPa (optimally 0.15MPa), and open the high-pressure container The liquid discharge valve of bin 3 recovers the liquid flowing out of the valve to make fertilizer mother liquor. After the liquid is discharged, the outlet of the high-pressure container compartment 3 is opened. The organic waste that has be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com