Chip-in micro-mixer and preparation method thereof

A technology of micro-mixer and chip, which is applied in fluid mixers, chemical instruments and methods, mixers, etc., can solve problems such as poor process compatibility, difficulty in mixing, and complex structure, so as to avoid bubbles or liquids Residue, cheap construction material, effect of improving mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the embodiment given with accompanying drawing.

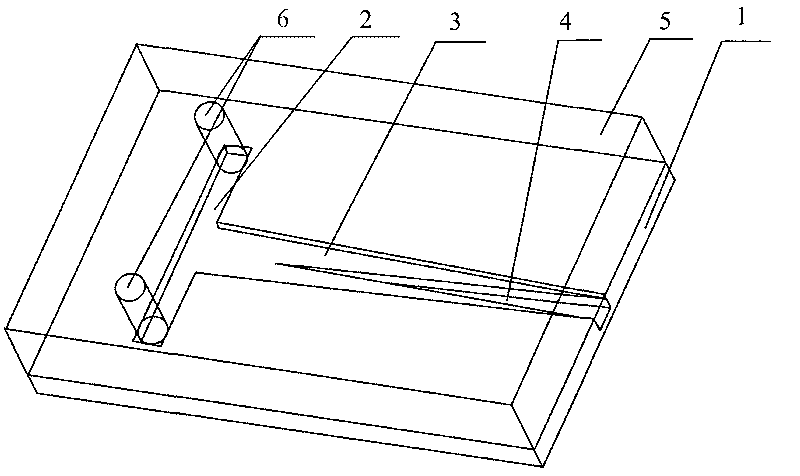

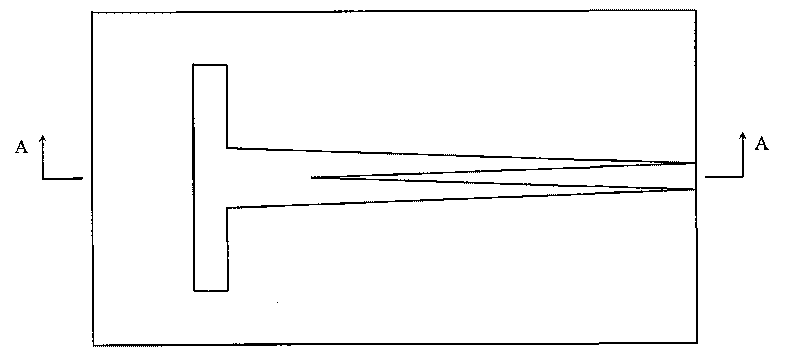

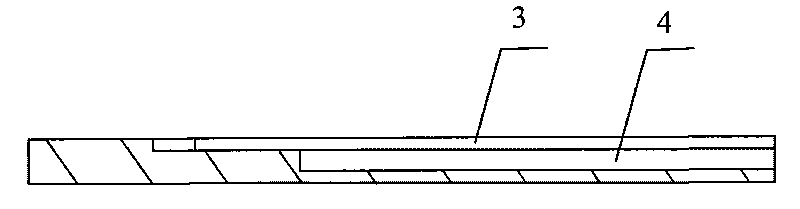

[0020] refer to Figures 1 to 3 , a micro-mixer in a chip, consisting of a PDMS substrate 1 and a glass plate 5 attached thereon, on the panel of the substrate 1 is provided with a transverse groove 2 and a connection with the outlet directly to the substrate The T-shaped groove formed by the longitudinal groove 3 at the plate end of the sheet 1, the longitudinal groove 3 is a tapered groove whose inlet width is greater than the outlet width connected to the transverse groove 2; A longitudinal inverted tapered groove 4 on the center line of the groove, the outlet width of the cone bottom of the inverted tapered groove 4 is equal to the outlet width of the longitudinal groove 3, and its tapered end reaches the entrance of the longitudinal groove 3 Rear part: through holes 6 communicating with the transverse groove 2 are respectively provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com