Anvil

The technology of top hammer and top surface is applied in the field of superhard material synthesis auxiliary equipment, which can solve the problems of serious economic loss and high price of the top hammer, and achieve the effects of low cost, reducing the probability of deflation gun, and ensuring safe pressure relief.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

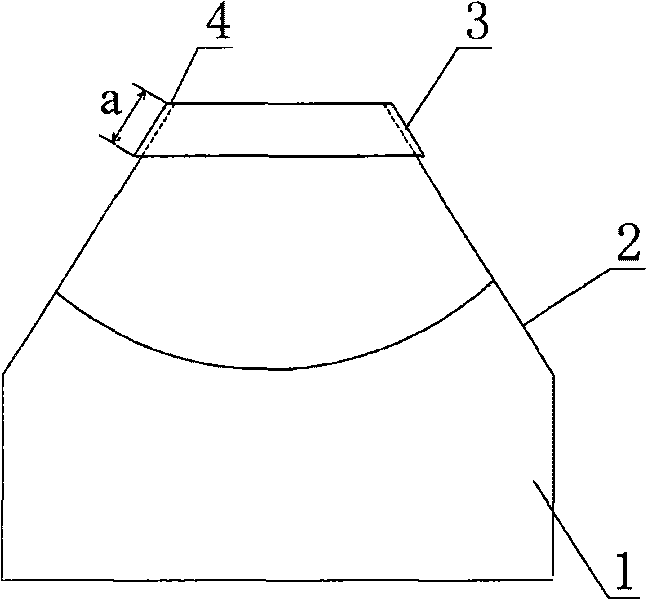

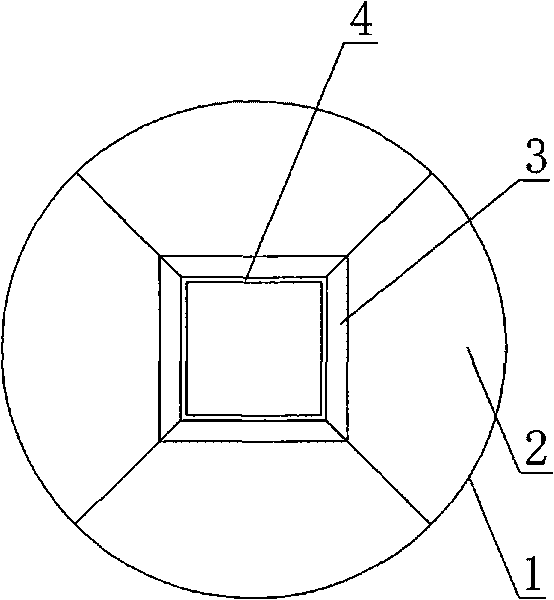

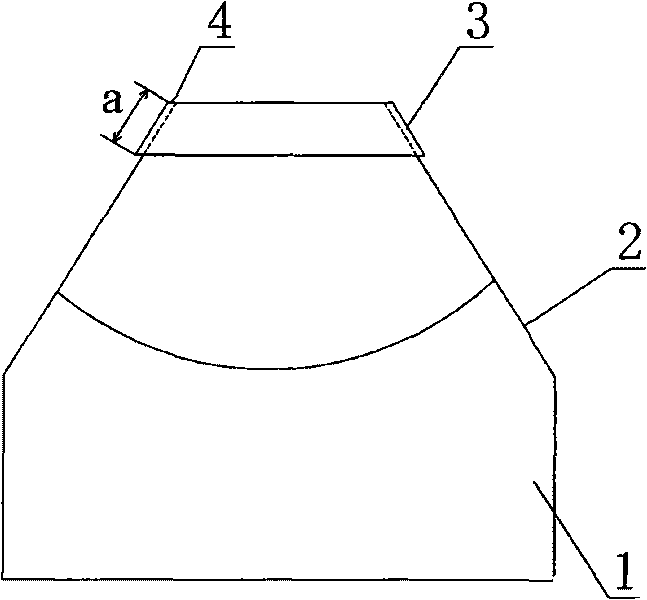

[0015] Such as figure 1 , figure 2 In the top hammer shown, a layer of coating 3 is electroplated on the upper slope 2 of the top hammer 1, and the coating 3 extends downward from the top surface 4 of the top hammer 1 along the slope 3, and its extension length a is 10-20mm. The coating layer 3 is formed by electroplating mixed tungsten powder and cobalt powder with high melting point, and the particle size of the tungsten powder and cobalt powder is 0.3 micron to ensure sufficient friction coefficient.

[0016] The coating 3 is added to the top hammer 1, so that the friction force between the slopes 2 is greatly increased, which can ensure safe pressure relief during the synthesis process, reduce the probability of deflation gun, and is safe and reliable.

[0017] In this embodiment, the extension length a of the plating layer 3 is 14 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extension length | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com