Piezoelectric type grinding force measuring device for ultraprecise grinding machine of silicon wafer

A measuring device, ultra-precise technology, applied in the field of sensor measurement and control, can solve problems such as difficult to monitor the grinding force accurately and in real time, cannot accurately determine the grinding force component Fx, etc., to improve reliability and production efficiency, hysteresis Small, highly sensitive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

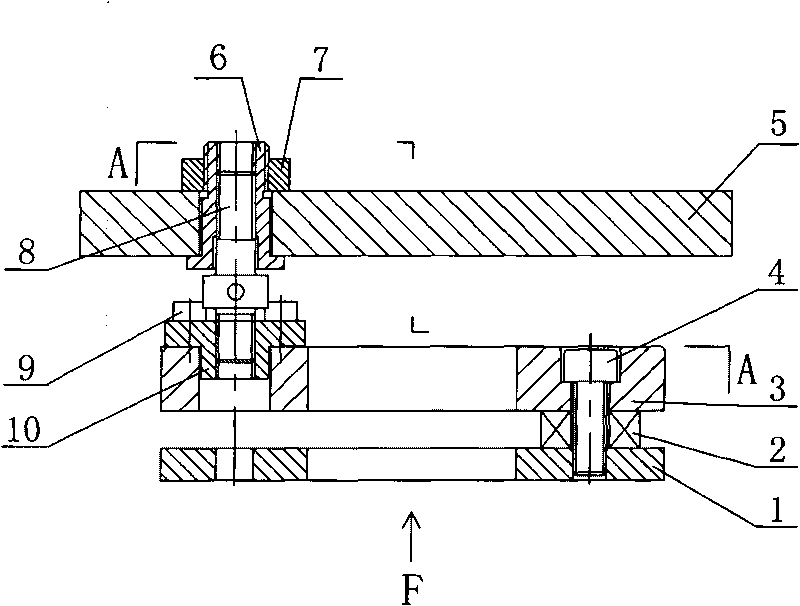

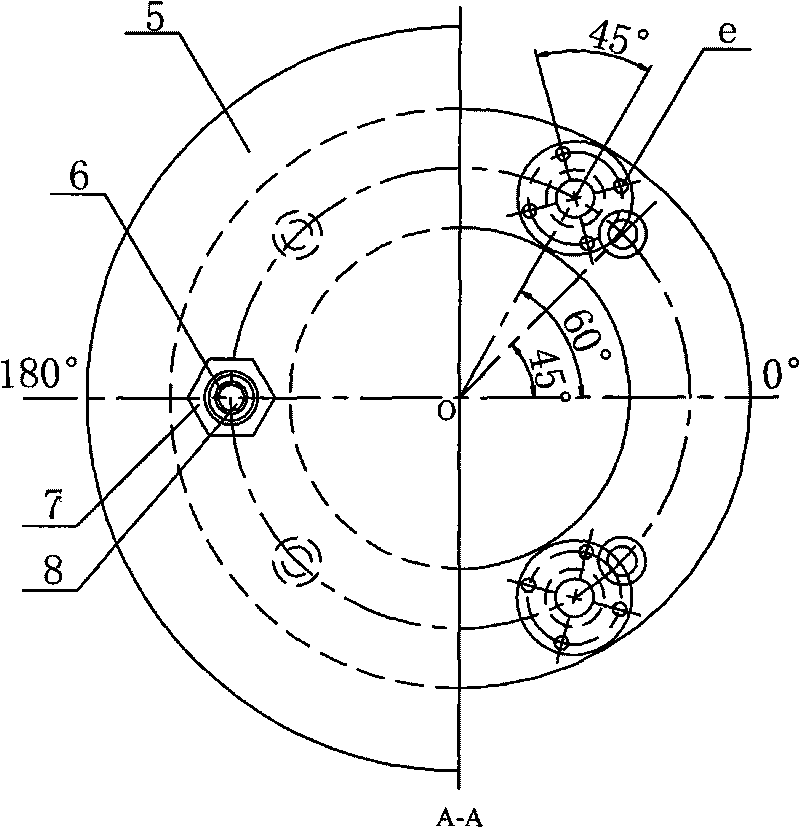

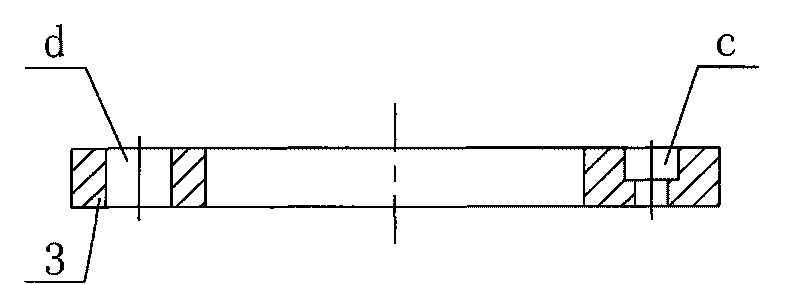

[0020] Example: The laboratory room temperature is 26°C, and the sensitivity of the charge amplifier YE5850B is S X =7.93pc / kgf, S Y =7.85pc / kgf, S Z =3.53pc / kgf, when the axial force acts, the force acts on the piezoelectric quartz force sensor 2 through the base 1, and the quartz crystal surface of a group of xy-type unit crystal groups o' with longitudinal effects will produce a corresponding Charge, the charge is transferred to the electrode v sandwiched between two quartz wafers, and the charge is drawn out through the negative signal lead-out line p of the axial force; when the radial force acts on the measuring device, the piezoelectric quartz force sensor 2 and the bottom plate 1 The friction force between the upper surface and the lower surface of the upper cover 3 applies radial force to the upper and lower surfaces of the piezoelectric quartz force sensor 2 Two groups of yx-type unit crystal groups with shearing effect o 1 , o 2 On the surface of the quartz cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com