Rosin-modified epoxy ester resin and preparation method thereof

An epoxy ester resin, rosin modification technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of brittle rosin, and achieve the effects of fast drying, high glass temperature, and excellent chemical resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

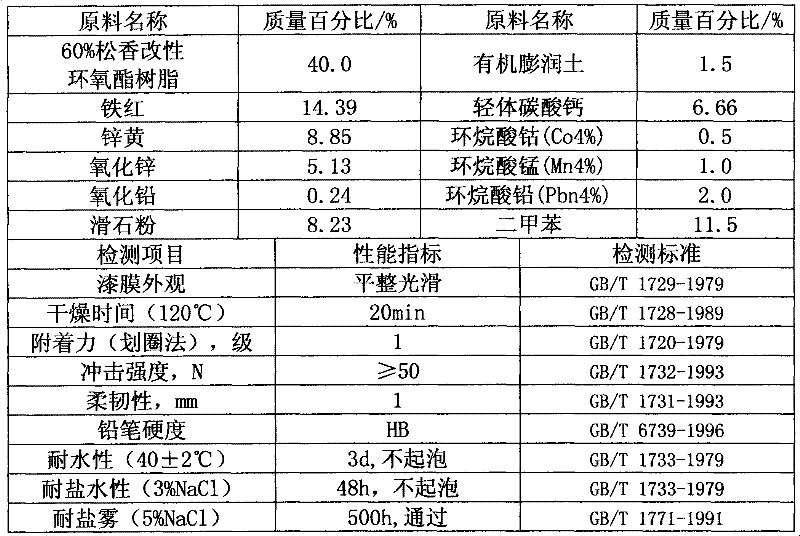

Image

Examples

Embodiment 1

[0029] (1) Add 60kg rosin and 60kg soybean oil into the reactor, seal it, start heating to 140°C, put in 100kg epoxy resin, raise the temperature to 180°C for 1 hour, and then react at 220°C for 3 hours.

[0030] (2) Cool down to 130°C, add 0.2kg of γ-valerolactone and react at 170°C for 1 hour.

[0031] (3) Cool down to 80°C and add 0.4kg of amino resin, react at 130°C for 1 hour, stop heating when the acid value drops below 10, immediately cool down, pump the esterified product into the dilution tank and cool down to 100°C Next, add 180kg xylene for dilution. Filtration starts below 60°C to obtain a rosin-modified epoxy ester resin.

Embodiment 2

[0033] (1) Add 50kg of rosin and 70kg of linoleic acid into the reactor, seal it, start heating to 140°C, put in 100kg of epoxy resin, raise the temperature to 180°C for 1 hour, and then react at 210°C for 4 hours.

[0034] (2) Cool down to 130°C, add 0.15kg of γ-valerolactone and react at 160°C for 1.5h.

[0035] (3) Cool down to 80°C and add 0.2kg of TDI, react at 100°C for 1 hour, stop heating when the acid value drops below 10, immediately cool down, pump the esterified product into the dilution tank and cool down to below 100°C , Add 180kg xylene for dilution. Filtration starts below 60°C to obtain a rosin-modified epoxy ester resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of esterification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com