Smoke-free gas burner

A technology of gas stove and no oil fume, applied in the field of gas stove, can solve the problems of heat loss, gas waste, pot weight, etc., and achieve the effect of preventing gas leakage, preventing the generation of oil fume, and ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

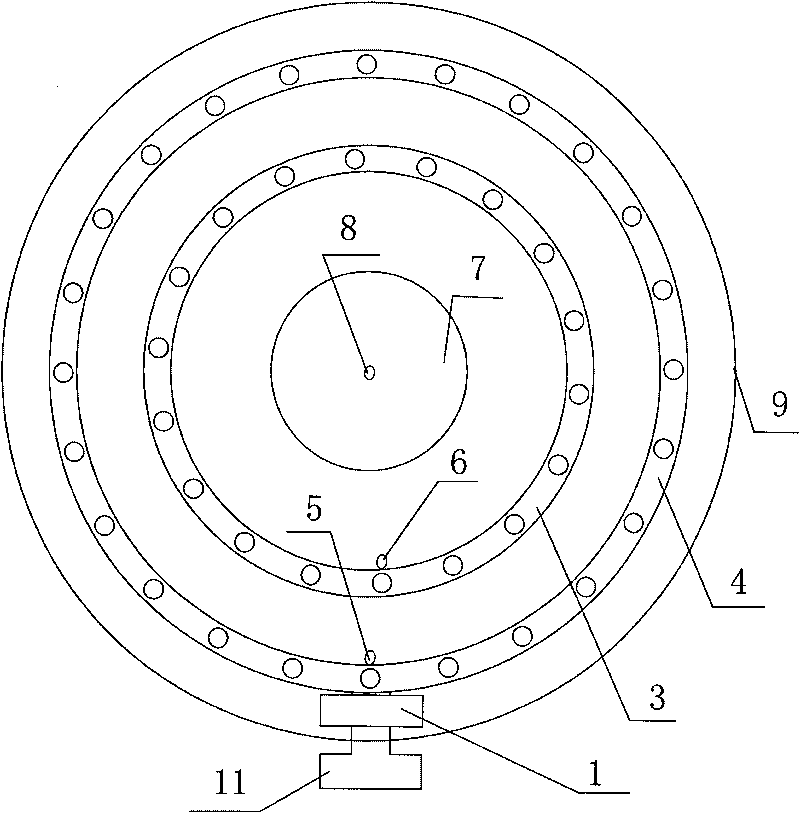

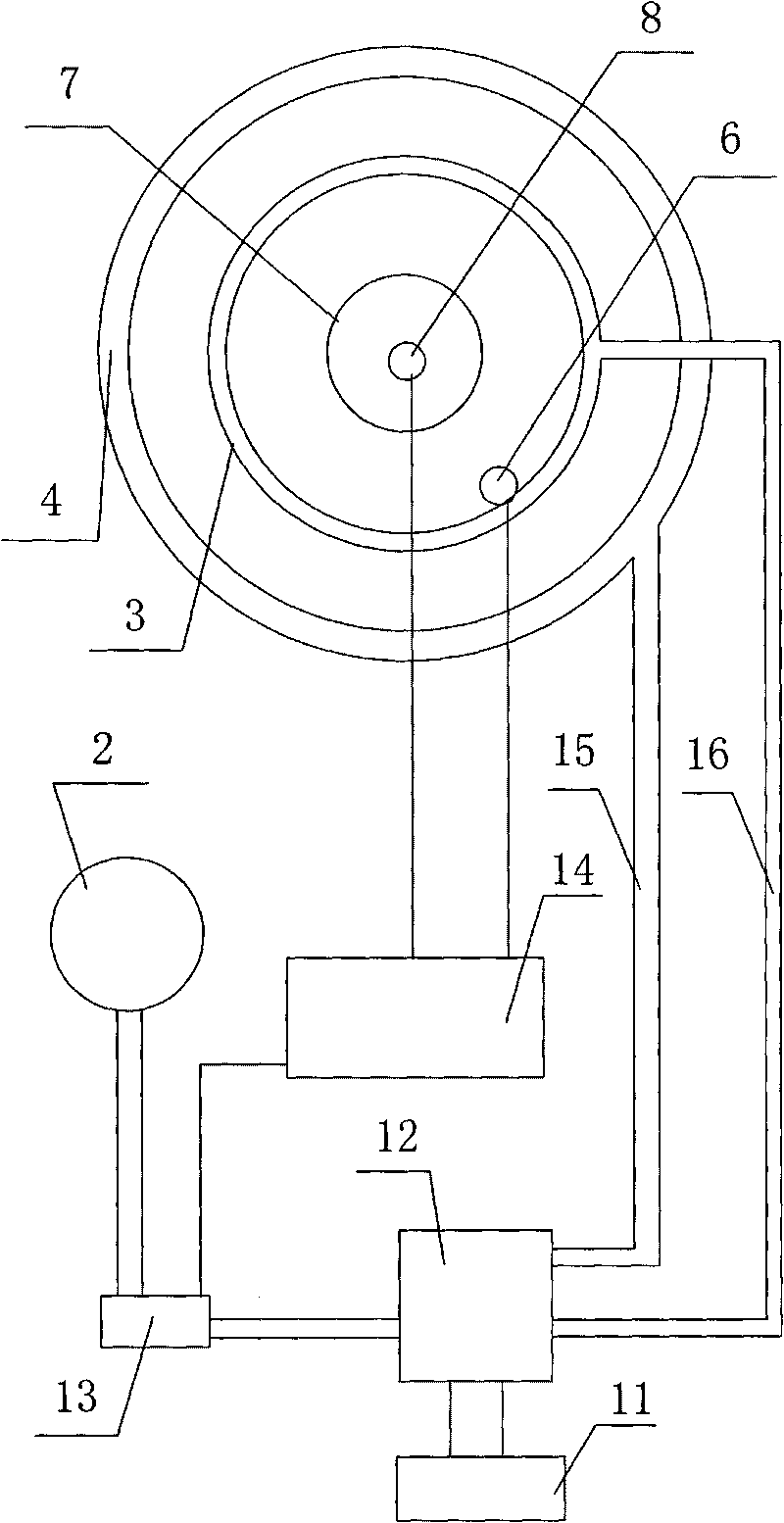

[0018] Such as figure 1 , figure 2 As shown, a fume-free gas stove includes a stove frame 9 provided with an ignition switch 11, inner and outer fire ring frames 3, 4 installed on the stove frame 9, and a liftable contact plate 7 located at the center of the stove frame 9 , the bottom of the contact plate 7 is provided with a spring or a lifting motor; the gas pipeline of the gas stove is provided with an ordinary valve 12 controlled by the ignition switch 11, and the ordinary valve 12 is fixed on the stove frame 9; the external gas source 2 of the gas pipeline is connected with the ordinary An electric control valve 13 that regulates the gas flow is installed between the valves 12. A single-chip microcomputer 14 that controls its work is connected to the electric control valve 13. The single-chip microcomputer 14 is connected with the ignition switch 11 that controls its working state. There is the first temperature sensor 8 that measures the temperature at the bottom of th...

Embodiment 2

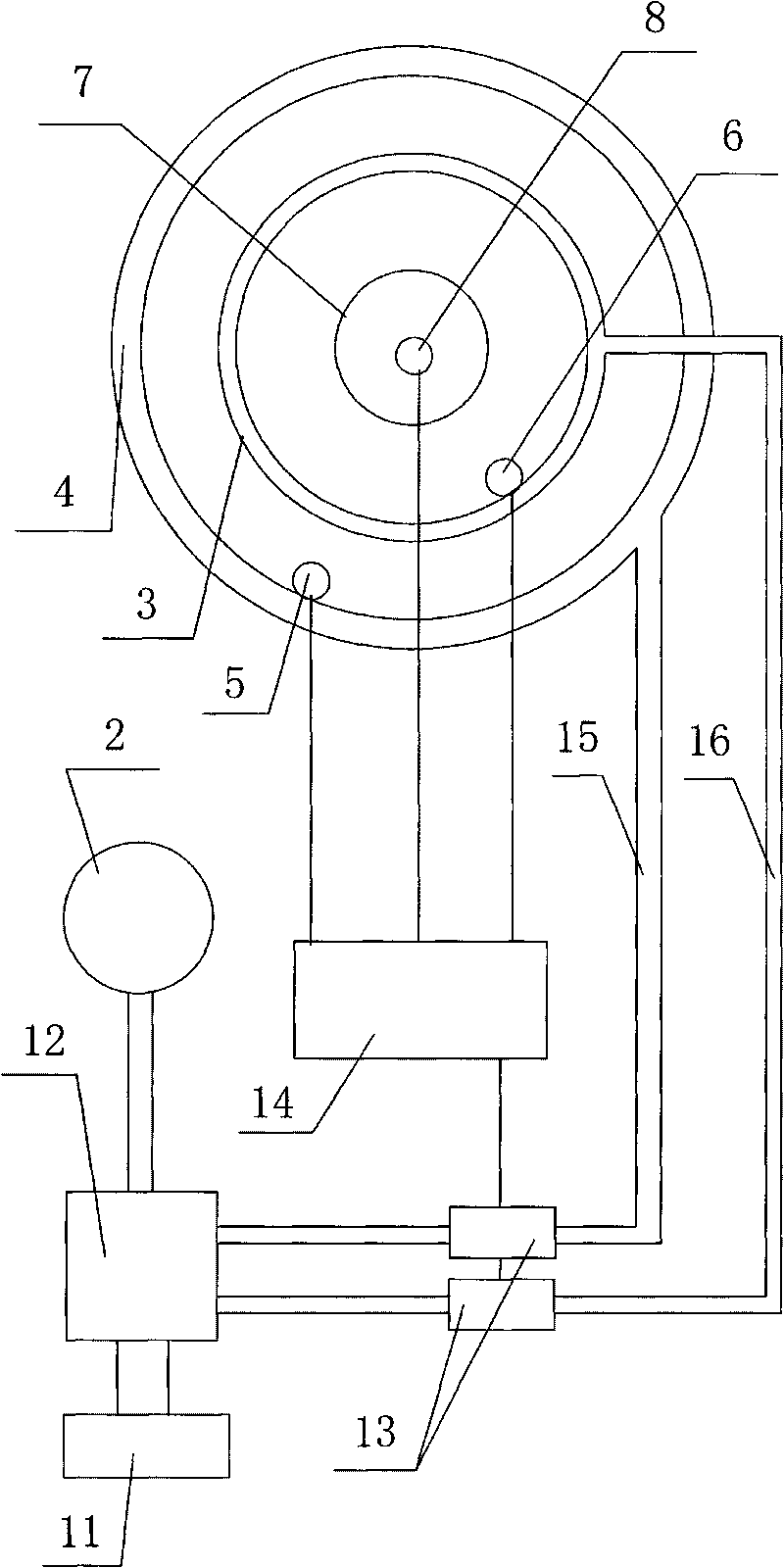

[0020] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the electric control valve 13 is installed on the inner and outer fire ring gas pipes 16, 15 between the ordinary valve 12 and the inner and outer fire ring frames 3, 4 , the working principle of the control of oil fume in this embodiment is exactly the same as that of Embodiment 1; as for the control of preventing gas leakage, in addition to setting the second temperature sensor 6 on the inner fire ring frame 3 and its vicinity, the outer fire ring The frame 4 and its vicinity are provided with the third temperature sensor 5 connected with the single-chip microcomputer 14, and the single-chip microcomputer 14 can separately carry out the opening and closing of two electric control valves 13 on the inner and outer fire ring gas pipes according to the temperature near the inner and outer fire rings. control.

Embodiment 3

[0022] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the electric control valve is composed of a common valve 12 on the gas pipeline and a servo motor 17 installed on the common valve 12 and controlling its flow. The single-chip microcomputer 14 of its work is connected.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap