Copper water heat pipe used in solar water heater

A technology of solar water heaters and copper water, applied in solar thermal power generation, solar thermal devices, indirect heat exchangers, etc., can solve problems such as high production costs, low production efficiency, and coarse grains, and achieve improved thermal conductivity and mechanical properties Improve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

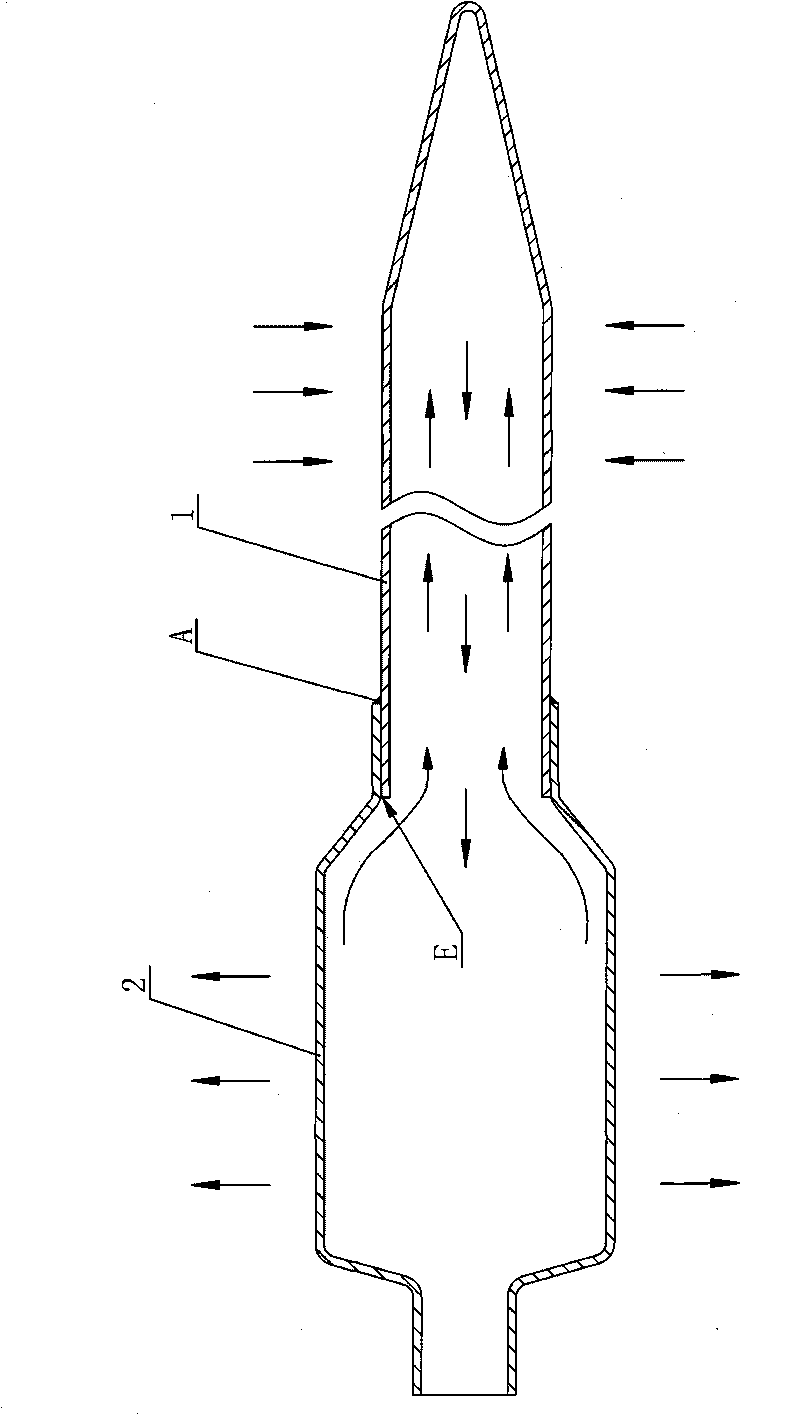

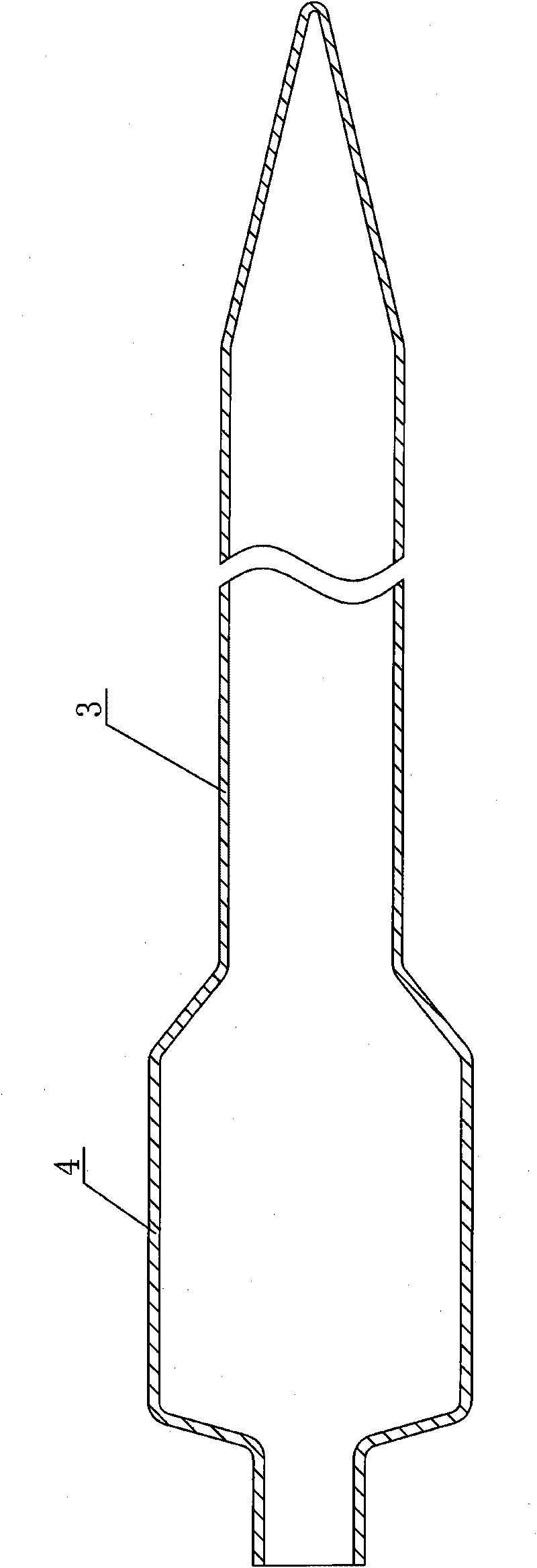

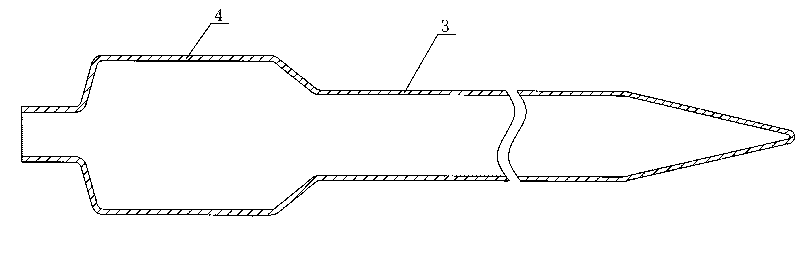

[0011] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0012] Such as figure 2 As shown, the copper water heat pipe used in the solar water heater includes: an evaporating section 3 and a condensing section 4, and the evaporating section 3 and the condensing section 4 are an integrated structure with a smooth transition connection. The wall thickness of the condensation section 4 is greater than that of the evaporation section 3 .

[0013] The copper water heat pipe used in the solar water heater is manufactured through the following process. The oxygen-free copper pipe is selected as the base material for drawing processing, extrusion molding, ultrasonic cleaning, mechanical performance testing, surface treatment, inspection, packaging factory.

[0014] The copper water heat pipe with the above structure used in solar water heaters has the following advantages: 1. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com