Composite control device of ignition furnace of sintering machine

A composite control and control device technology, applied to furnaces, furnace types, lighting and heating equipment, etc., can solve problems such as weak anti-interference ability, poor precision, unsatisfactory accuracy, etc., and achieve good economic and social benefits , Improve the sintering speed and stabilize the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

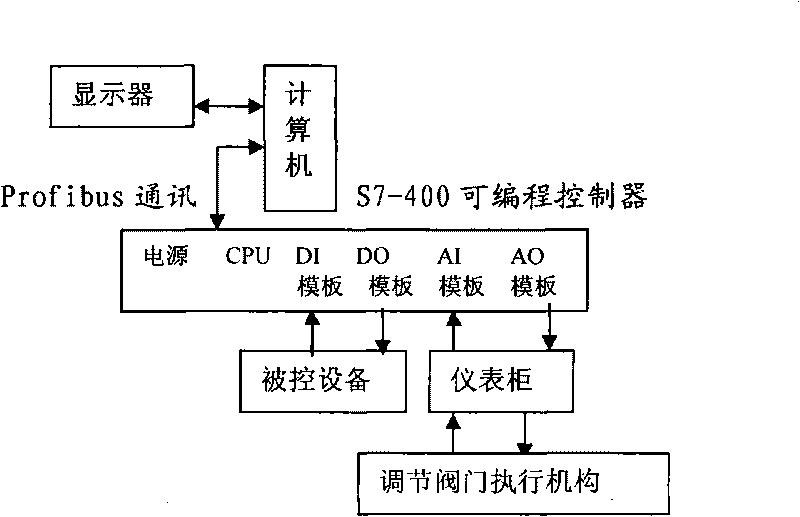

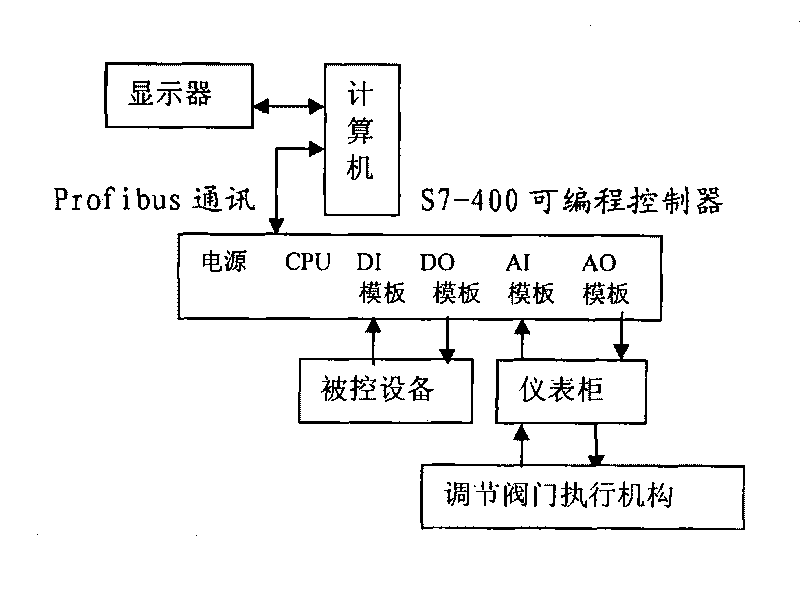

[0016] Such as figure 1 As shown, the composite control device of the sintering machine ignition furnace of the present invention includes a detection instrument and a control device, and is characterized in that the control device includes an industrial computer, and a programmable logic controller connected to the industrial computer respectively PLC, the instrument cabinet connected to this programmable logic controller PLC, the regulating valve actuator connected to this instrument cabinet, this programmable logic controller PLC is also connected to the controlled equipment, this programmable logic controller Fuzzy-PID composite control program is installed in the controller PLC.

[0017] The programmable logic controller PLC is provided with a CPU, and a digital input module, a digital output module, an analog input module, and an an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com