Method for manufacturing nano powder

A nano-powder and manufacturing method technology, applied in the field of nano-powder manufacturing, can solve problems such as difficult to accurately control chemical composition and limited application, and achieve the effects of easy mass production, narrow particle size distribution, and easy manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

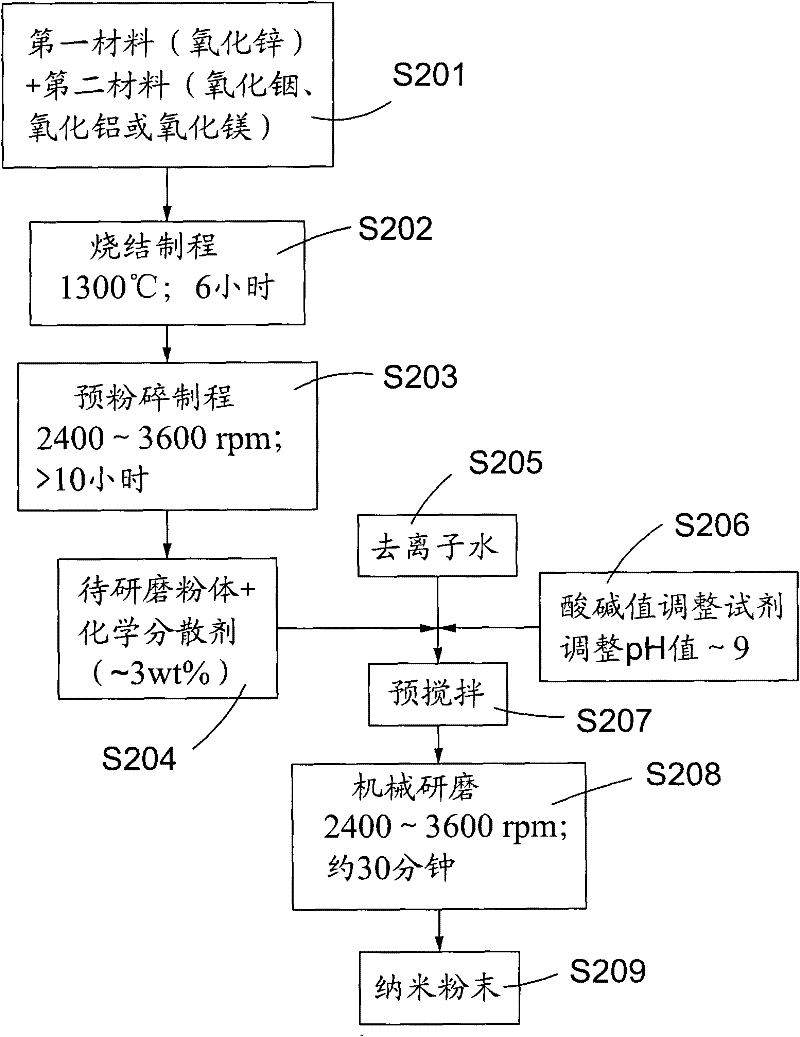

[0027] figure 2 It is a schematic flowchart of the steps of the manufacturing method of the nano-powder according to the first embodiment of the present invention. Please refer to figure 2 , the nano powder manufacturing method 200 generally includes steps S201-S209. First, as shown in step S201, a mixture is provided, and the mixture at least includes a first material and a second material. In this embodiment, the first material may be zinc oxide, and the second material may be indium oxide, aluminum oxide or magnesium oxide.

[0028] Nanopowders such as zinc oxide, indium oxide, aluminum oxide, and magnesium oxide are directly available in the market. However, if the size of the powder used is not nano-scale, preliminary mechanical grinding can also be carried out first. In particular, in step S201, the addition amounts of the first material and the second material may be determined according to a specific chemical composition. In the step of simply mixing solid powde...

no. 2 example

[0043] Figure 5 It is a schematic flowchart of the steps of the nano powder manufacturing method according to the second embodiment of the present invention. Such as Figure 5 The manufacturing method of the nanopowder shown includes steps S301 to S309, and the related content is as follows: figure 2 The fabrication method of the shown nanopowders is similar and will not be repeated here.

[0044] It should be noted that in step 301, a mixture is provided, and the mixture at least includes a first material and a second material. In this embodiment, the first material is barium oxide and the second material is titanium oxide. After continuing through the steps S302-S309, the nanometer powder of barium titanate (BaTiO3) can be obtained.

no. 3 example

[0046] FIG. 6 is a schematic flowchart of the steps of the method for manufacturing nanopowder according to the third embodiment of the present invention. The manufacturing method of nanopowder as shown in Figure 6 comprises steps S401~S409, relevant content is as follows figure 2 The fabrication method of the shown nanopowders is similar and will not be repeated here.

[0047] It should be noted that in step 401, a mixture is provided, and the mixture includes a first material, a second material and a third material. In this embodiment, the first material is zinc oxide, the second material is indium oxide, and the third material is gallium oxide. In this embodiment, the molar ratio of zinc oxide, indium oxide and gallium oxide is 2:1:1. After continuing to go through steps S402-S409, nanometer powder of indium gallium zinc oxide (IGZO) can be obtained.

[0048] In more detail, the general process is as follows: first mix powder materials such as zinc oxide (ZnO), indium o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com