Method for manufacturing beveled ball valve

A manufacturing method and ball valve technology, applied in the direction of manufacturing tools, clamping, supporting, etc., can solve the problems of air holes in the valve body, endangering personal safety, easy leakage, etc., and achieve high valve body density, ensuring personal safety and production safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

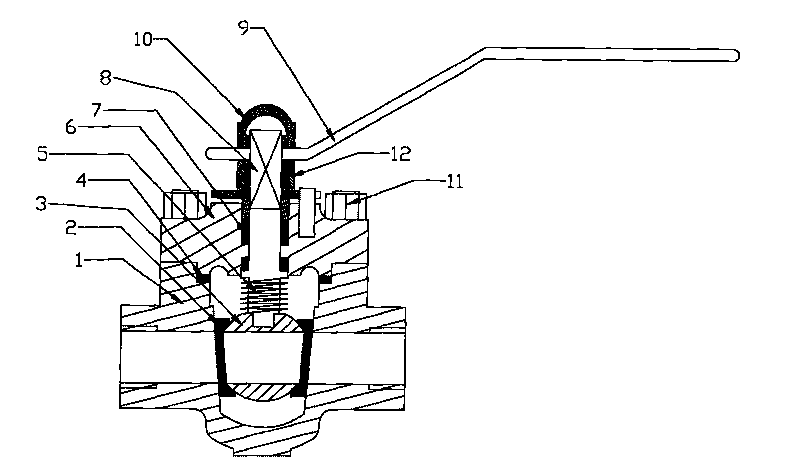

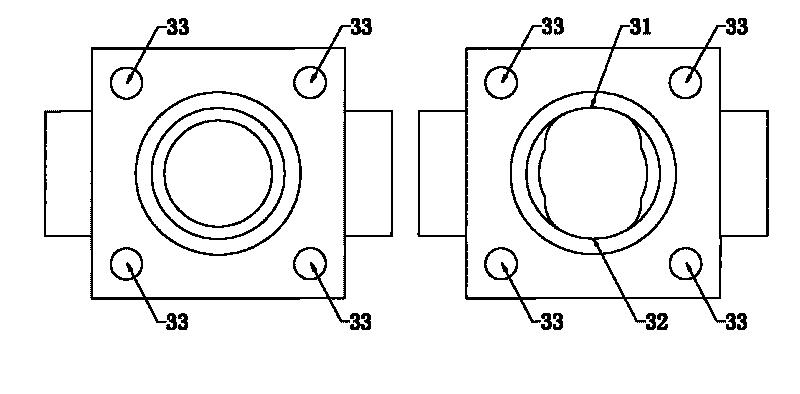

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] The manufacturing method of inclined-plane ball valve of the present invention, its concrete steps of preparing inclined-plane ball valve valve body are:

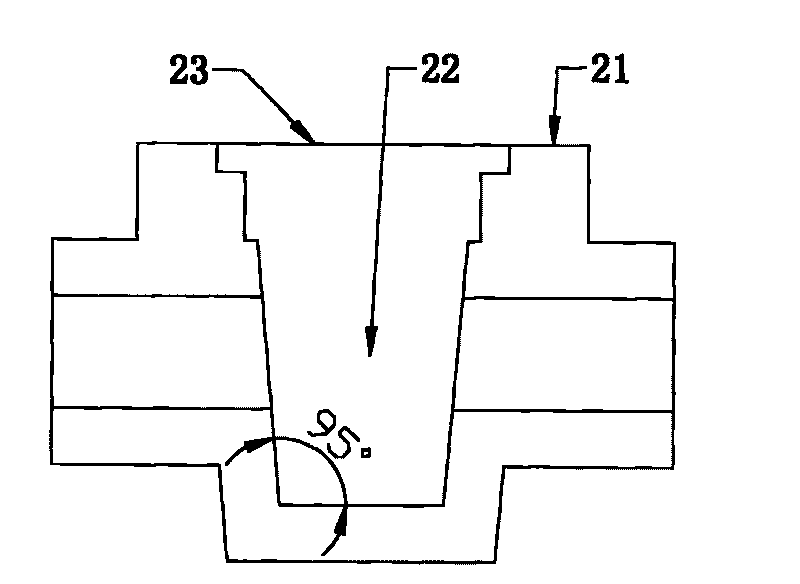

[0037] Step 1, according to the valve body specifications of the inclined ball valve, cut the round steel bar;

[0038] Step 2, preparing the blank of the inclined ball valve body: at a high temperature of 600-800 ° C, the round steel bar is made soft, and then put it into the rough mold of the inclined ball valve body, and punched into an inclined ball valve with a friction punch When the temperature of the rough billet of the inclined ball valve body is still high, put the rough billet of the inclined ball valve body into the mold of the fine billet of the inclined ball valve body, and use a friction punch to punch it into a fine billet of the inclined ball valve body. Put the valve body blank in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com