Polyvinyl alcohol fiber reinforced cement-based material composition and preparation method and application thereof

A technology of polyvinyl alcohol fiber and reinforced cement, applied in the field of building materials, can solve problems such as endangering building safety, affecting structural stress state, accelerating freeze-thaw damage, etc., and achieves high crack resistance, low cost and high durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4、 comparative example 1、2

[0029] Embodiment 1-4, comparative example 1, 2: raw material proportioning

[0030] According to the proportioning ingredients in Table 1:

[0031] Unit: parts by weight

[0032]

[0033]

Embodiment 5

[0034] Embodiment 5: prepare cement prism

[0035] According to the ratio in Table 1, adopt the following steps to make 6 cement prisms with a size of 40×40×160mm:

[0036] 1) Mix sand, cement, fly ash, silica fume and finely ground quartz powder, add water and stir evenly;

[0037] 2) Add high-efficiency water reducer and mix evenly; (the comparative example does not carry out step 3)

[0038] 3) Add polyvinyl alcohol fiber and stir evenly;

[0039] 4) Pouring into a prism;

[0040] 5) Vibrate and compact;

[0041] 6) Maintain for 24 hours.

Embodiment 6

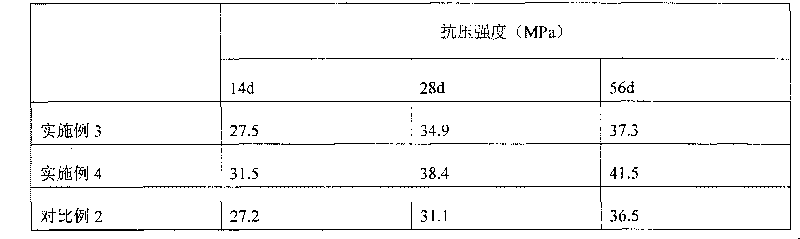

[0042] Embodiment 6: the experiment to embodiment 5 prism shrinkage and anti-crack performance

[0043] According to relevant national standards, 6 prisms obtained in embodiment 5 are subjected to following experiments: four-point bending experiment, restricted contraction experiment, compressive strength experiment (embodiment 3,4, comparative example 2), the results are as follows:

[0044] Table 2: Results of four-point bending test and restrictive shrinkage test

[0045] Example

total crack area

A(mm 2 )

number of cracks

N (articles)

crack width

(mm)

Average crack width C

(mm)

Crack Control Rate

K(%)

Example 1

4.09

4

0.11

0.068

91.5

Example 2

1.77

6

0.04

0.021

96.3

Comparative example 1

48.00

1

3.20

3.20

----

2.21

4

0.06

0.038

95.0

1.46

5

0.04

0.020

96.7

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com