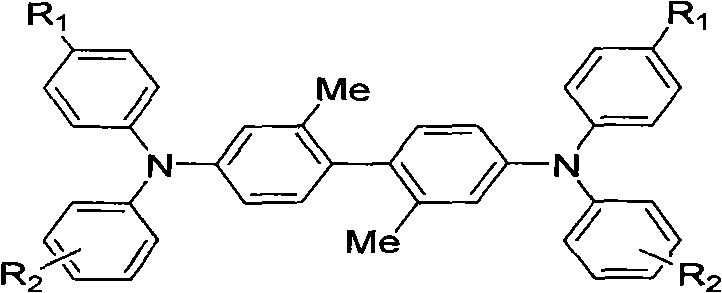

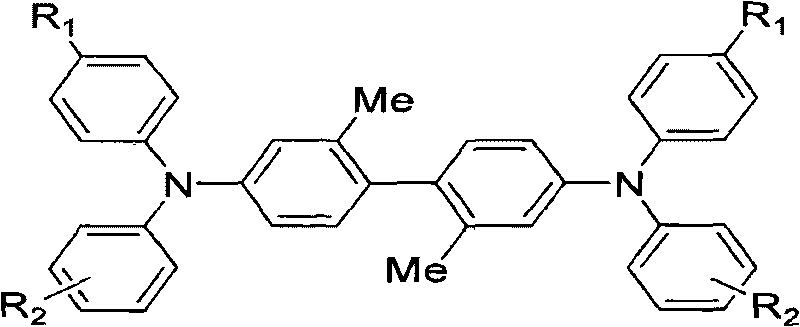

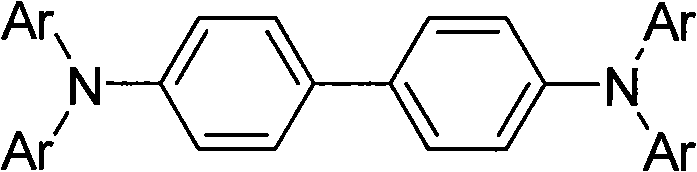

Preparation method and application of TPD hole transport material with crystallization resistance

A technology of hole transport materials and anti-crystallization, which is applied in the preparation of organic compounds, preparation of amino compounds, chemical instruments and methods, etc., can solve the problems of loss of function, deterioration of device performance, etc., achieve excellent anti-crystallization, and solve the problem of device Performance deterioration or even loss of function, the effect of excellent hole transport ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, the preparation method of the TPD hole transport material of the present invention is: in a mechanically stirred 500 ml three-necked bottle, put 21.7 grams (0.05 moles) of 2,2'-dimethyl-4,4'-di Toluene, 23.6 g (0.12 mol) 4,4'-dimethyldiphenylamine, 55 g (0.4 mol) potassium carbonate, 6.8 g (0.1 mol) copper powder (200-300 mesh) and 150 ml o-dichloro Benzene; under the protection of nitrogen, the mixture was heated to 180-185 ° C while stirring. After 24 hours, the reaction mixture was cooled to room temperature, 100 ml of water was added, the organic phase was separated, and then washed with 100 ml of water; the organic phase was washed with Dry magnesium sulfate over water, filter, remove o-dichlorobenzene by distillation under reduced pressure, pour into 200 ml of methanol, and stir vigorously to precipitate a precipitate; filter with suction to obtain a crude product of light yellow solid powder; dry the crude product in 100 ml of volume ratio 1:4 Recry...

Embodiment 2

[0021] Embodiment two, the TPD hole transport material of the present invention is used in the manufacture method of organic photoconductor drum is: in the ball mill tank of 500 milliliters, add 3 grams of Y-TiOPc, 2 grams of PVB, 250 milliliters of cyclohexanone and 200 milliliters of Reinforced glass beads (Φ2-3mm) were dispersed on a ball mill with a rotating speed of 180 rpm for 6 hours; the obtained CGM coating solution was coated on an aluminum drum base (diameter 24mm, length 240mm) by dip coating, 80 °C for half an hour to obtain a charge generation layer with a thickness of about 0.5 μm. Then, a solution formed by dissolving 10 grams of N-TPD-1 and 20 grams of PCZ-300 in 300 milliliters of tetrahydrofuran was coated on it, and dried at 100° C. for 1 hour after coating to obtain a charge (hole) transport with a thickness of about 15 μm. Floor.

[0022] The N-TPD-1 is replaced by N-TPD-2, N-TPD-3, m-TPD or TTPD.

[0023] The performance test and anti-crystallization i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com