Valve seat material, valve seat, main valve and four-way reversing valve

A valve seat and heat exchanger technology, used in valve devices, refrigeration and liquefaction, lighting and heating equipment, etc., can solve problems such as heat loss and waste, reduce heat loss, improve energy-saving effects, and meet sealing requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

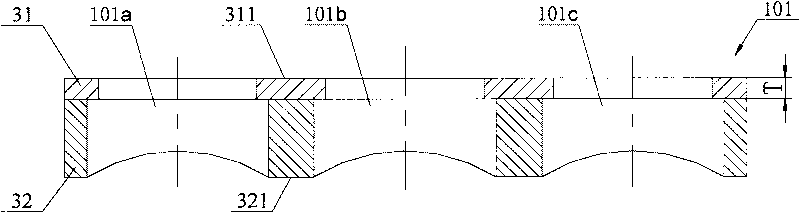

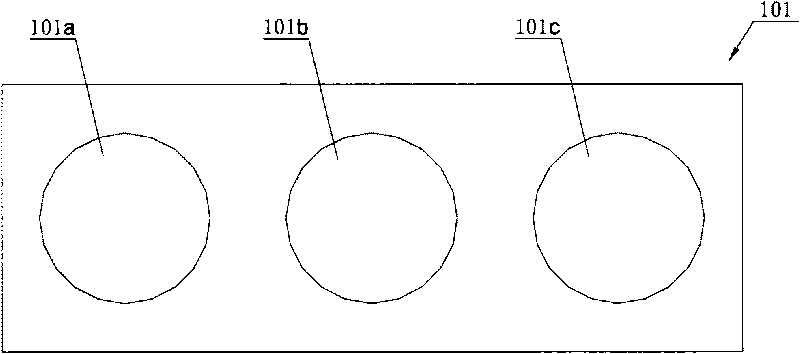

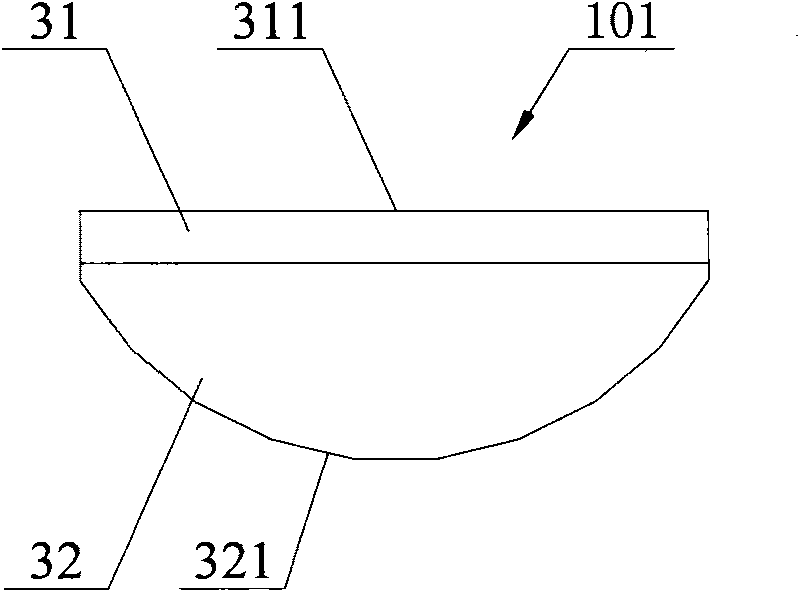

[0045] For the preparation method of the valve seat material, the present invention has no special limitation, and methods well known to those skilled in the art can be used for preparation. That is, the copper alloy solution is adjusted to meet the above requirements by adding alloy elements, and then the finished bar is obtained by casting, hot rolling, cold rolling and annealing, etc., and then processed into valves by machining. seat. Casting can be continuous casting, direct chill casting and other methods, the temperature of hot rolling can be 660°C-960°C, and the annealing temperature can be 410°C-610°C. The valve seat of the present invention can be used for a solenoid valve or a reversing valve, and the reversing valve can be a reversing valve for an air conditioner or a refrigerator, and the air conditioner can be a cold-only air conditioner or a heat pump air conditioner. Preferably, the The reversing valve described above is a four-way reversing valve in a heat pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com