Over-current protection device for physical vapor deposition heating system

A technology of physical vapor deposition and heating system, applied in the field of overcurrent protection device of physical vapor deposition heating system, can solve the problems of smaller heating load, larger heating current, short circuit, etc., to avoid repeated fluctuations and reduce repeated changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

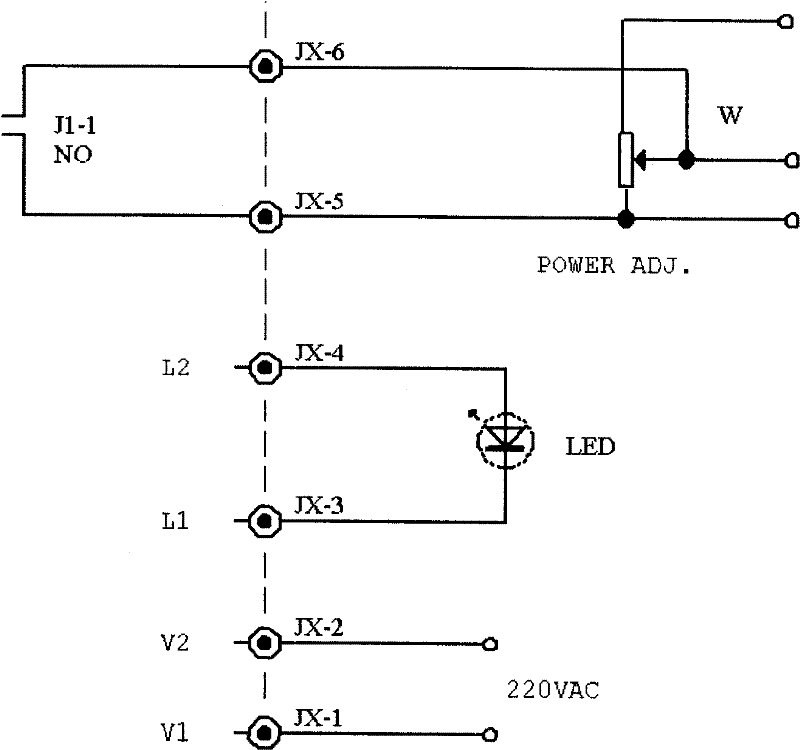

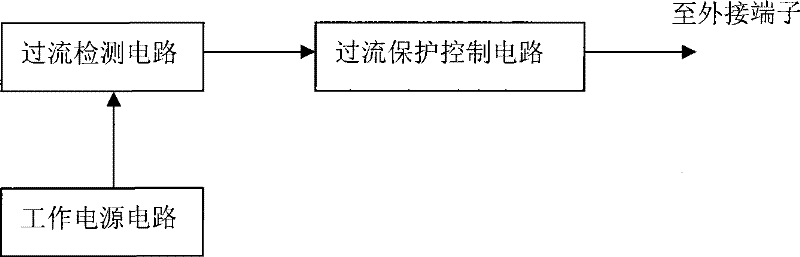

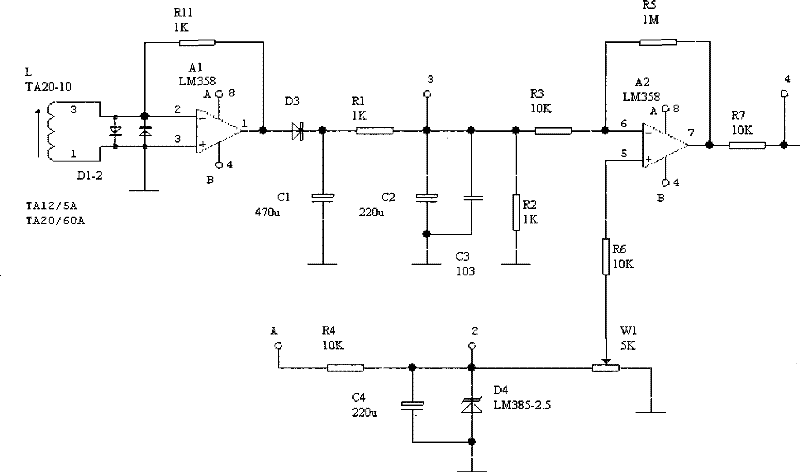

[0015] Such as Figure 1~4 As shown, the physical vapor deposition heating system overcurrent protection device of the present invention has an overcurrent detection circuit, an overcurrent protection control circuit and a working power supply circuit, wherein the overcurrent detection circuit detects the current of the heating system heating power line through the induction coil L, and after processing Finally output the trigger signal; the over-current protection control circuit receives the trigger signal output by the over-current detection circuit, and delays to control the current given signal of the current adjustment potentiometer W of the heating system; the working power circuit is the electrical device in the above-mentioned circuits Provide working power.

[0016] The overcurrent detection circuit has an induction coil L for detecting the heating power line current of the heating system, the current signal of the induction coil L is connected to the negative input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com