Continuous feeding device for alumina

A technology of feeding device and alumina, which is applied in the field of continuous alumina feeding device for pre-baked aluminum electrolytic cells, can solve the problems of imbalance, increase carbon fluoride gas emission, increase power consumption and material consumption of electrolytic aluminum, and achieve stable stability Balance, reduce power consumption, reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

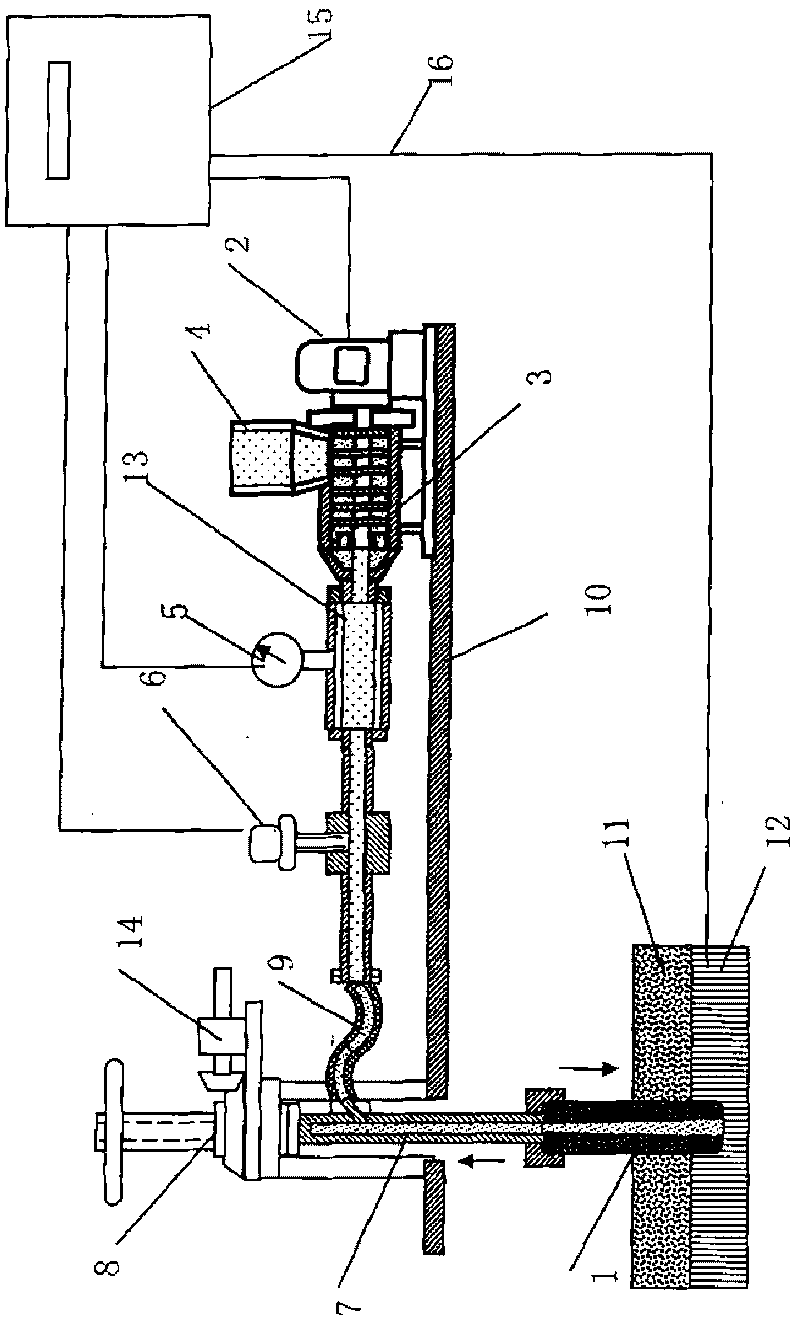

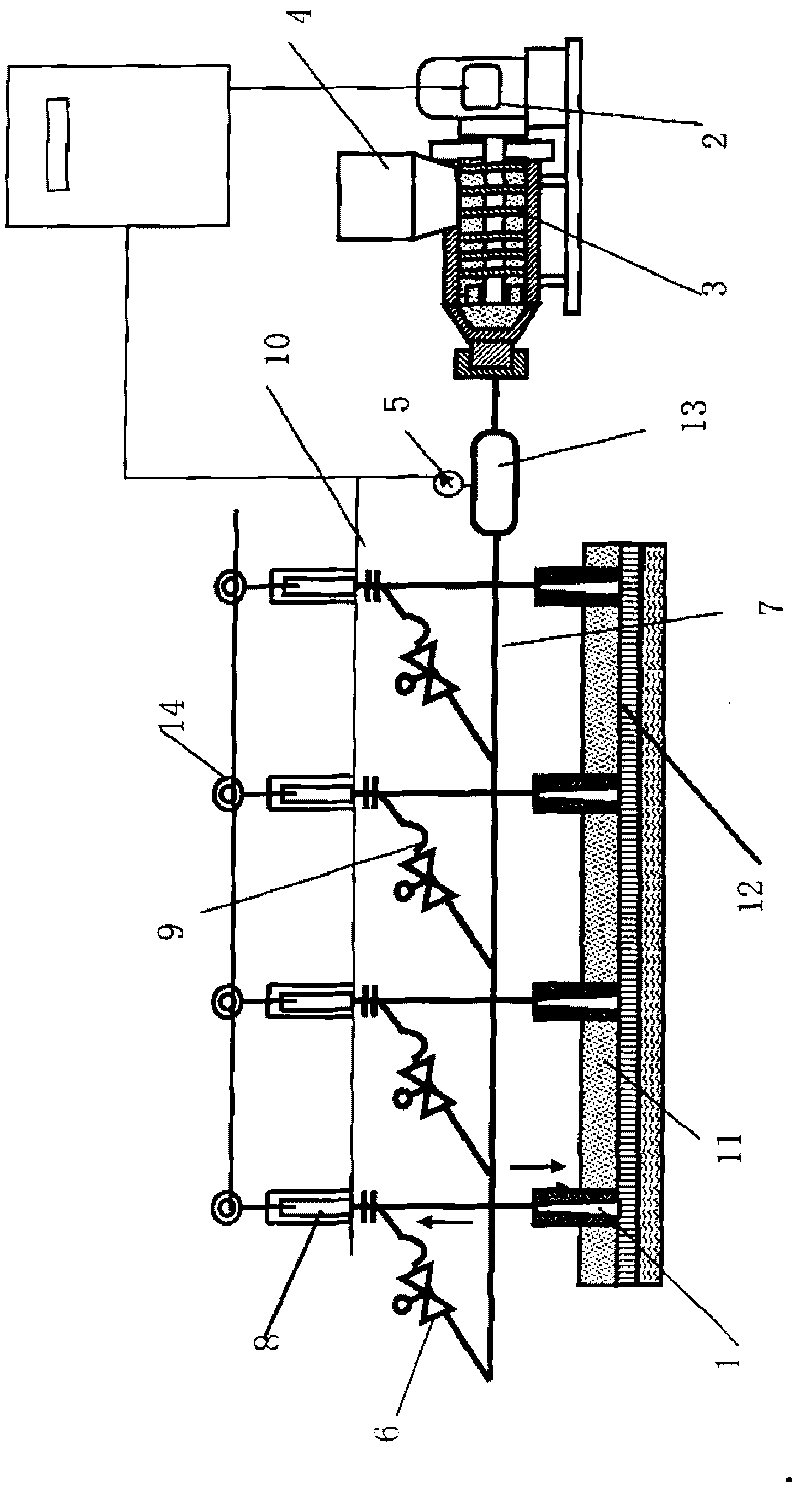

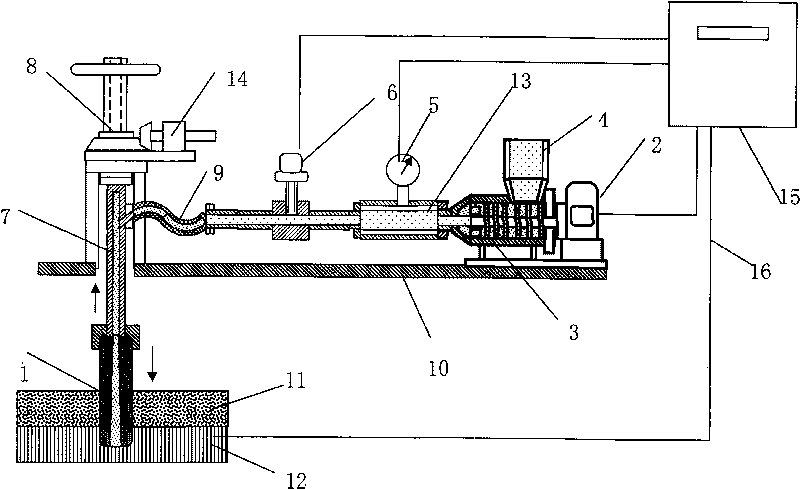

[0013] The concrete embodiment of shelling device for aluminum electrolytic cell of the present invention is:

[0014] The alumina continuous feeding device consists of injection pipe (1), pressurized pump frequency conversion motor (2), alumina pressurized pump (3), feeding box (4), pipeline pressure relay meter (5), flow control valve (6 ), conveying pipeline (7), lifting and pressing device (8), and connecting parts are constructed.

[0015] On the upper structure of the electrolytic cell (10), the lifting and pressing device (8) of the alumina powder injection pipe (1) is set, so that the alumina powder injection pipe (1) passes through the alumina crust (11), It is in liquid communication with the electrolyte (12), and the variable frequency booster pump (3) is used to drive the variable frequency booster pump (3) to pressurize the alumina powder, and the sealed delivery pipe (7) and delivery hose (9) are used to pass through the injection pipe (1), continuously injected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com