Novel house wall

A new type of house and wall technology, applied in the direction of walls, building components, insulation, etc., can solve problems such as deflection, low seismic strength of house walls, poor stability, etc., to ensure wall strength, expand the use range, and sound insulation effect Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

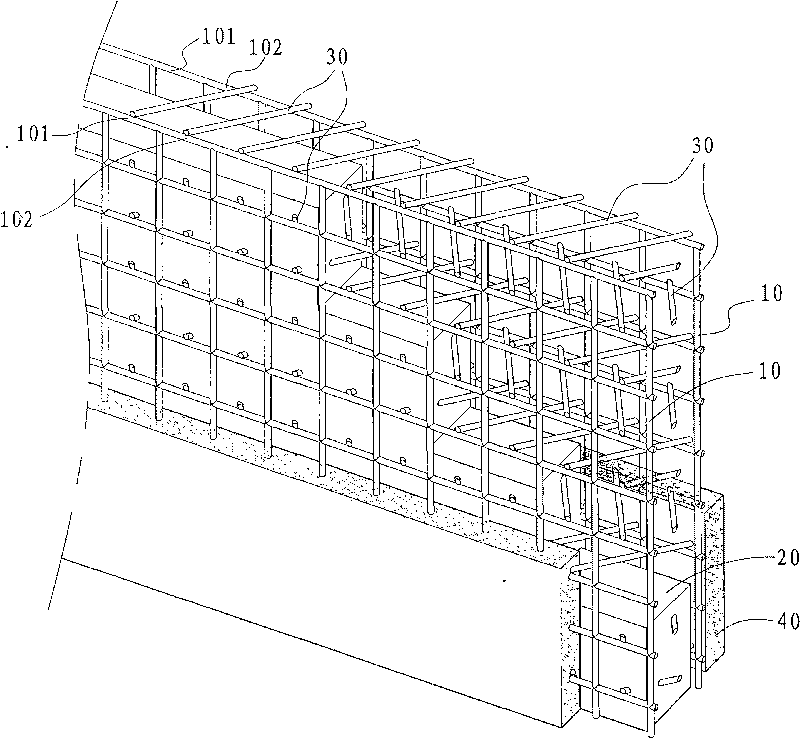

[0034] Such as Figure 4 and Figure 5 Shown is a preferred embodiment of the present invention.

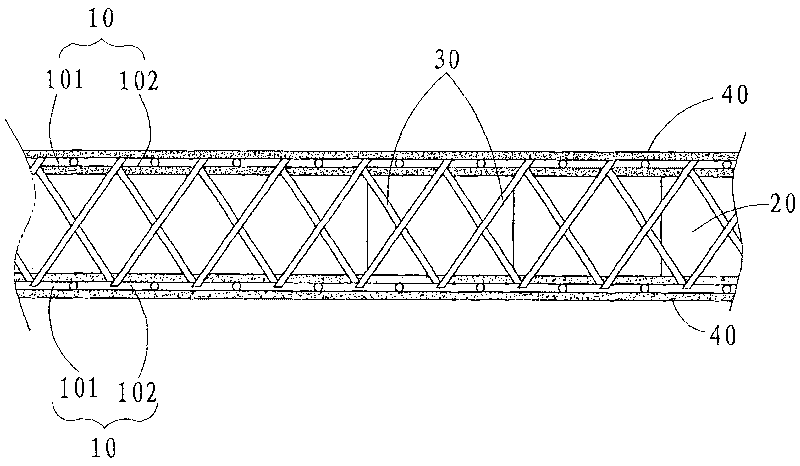

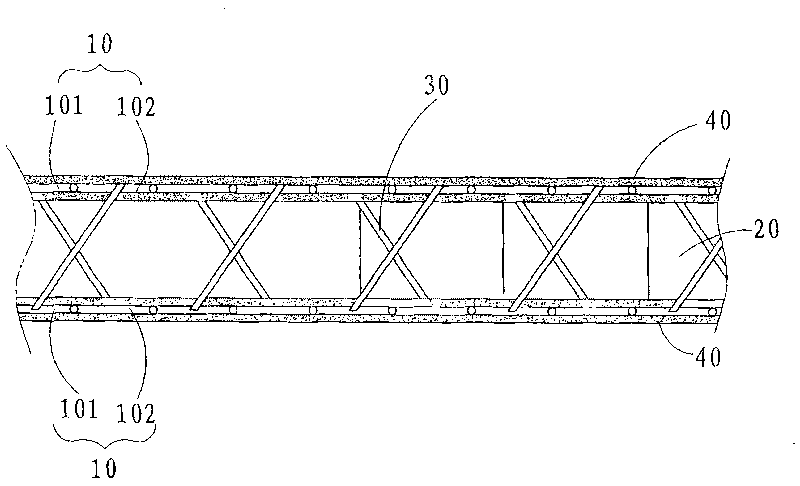

[0035] A new type of house wall disclosed in this embodiment is welded with steel wires to form two mesh sheets 1, and the grids of the two mesh sheets 1 are opposite to each other. A foam board 2 is filled between the two mesh sheets 1 . There are also oblique wires 3 between the two meshes 1, the oblique wires 3 are interspersed on the foam board 2 and the two ends are respectively welded on the two meshes 1, the oblique wires 3 are located in the same row in the same direction of inclination, The inclination directions of two adjacent rows are opposite. A cement mortar layer 4 is applied on the two mesh sheets 1 . The invention also has the advantages of heat insulation, high strength, shock resistance, moisture and fire prevention, sound insulation, light weight, and convenient architectural design.

[0036] The improvements of the present invention are as Figure 5 As ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap