Supporting special noise elimination air release assembled valve of high-speed centrifugal fan

A high-speed centrifugal, combined valve technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of reduced service life, erosion, high humidity in the occasion, and achieve simple and convenient replacement, low manufacturing cost, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

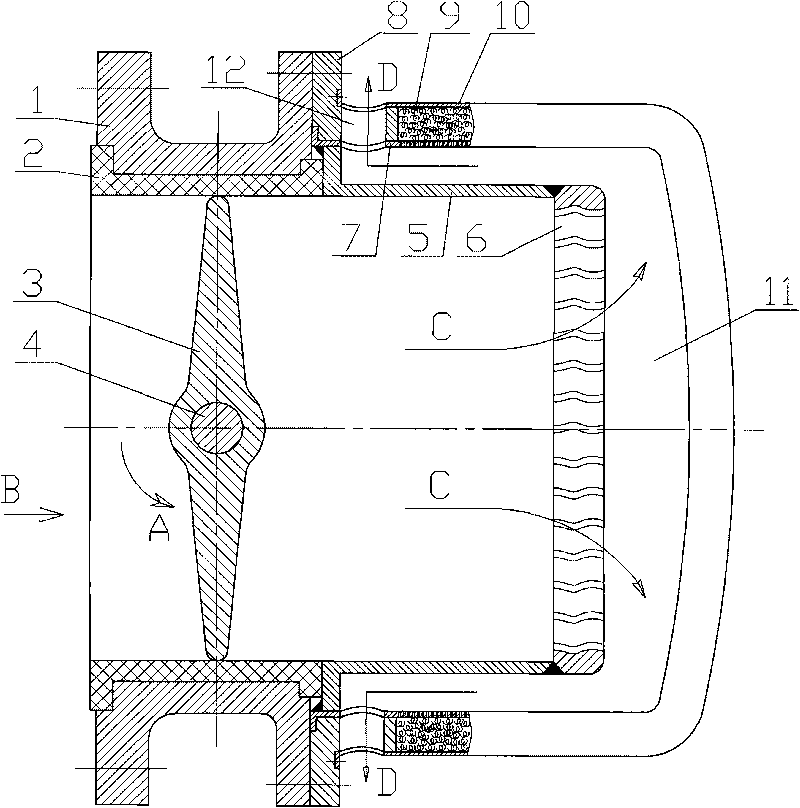

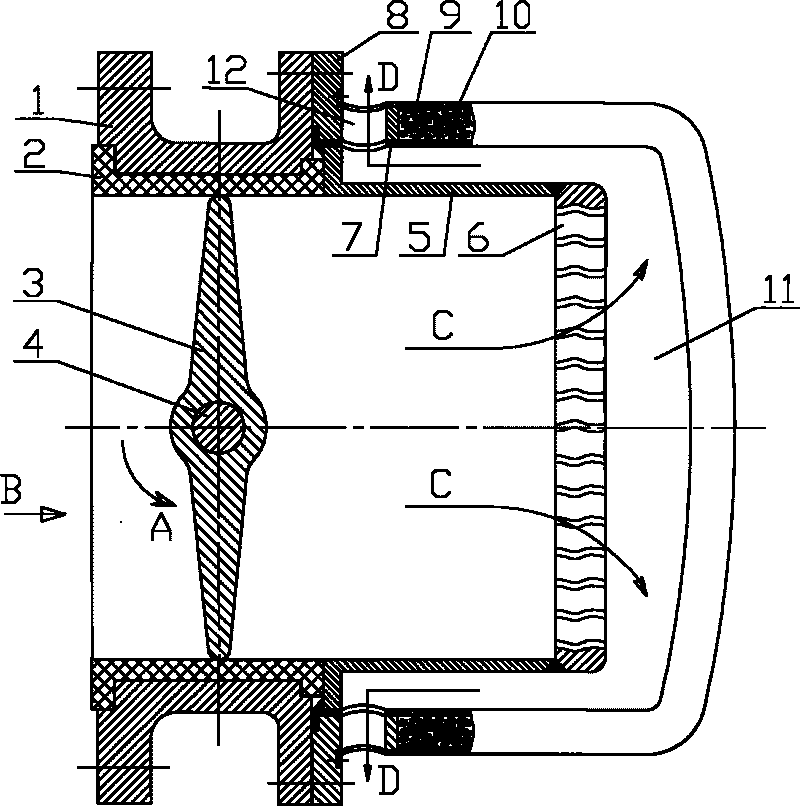

[0010] Such as figure 1 Shown: the present invention includes valve body 1, sealing lining 2, butterfly plate 3, valve stem 4, supporting core sleeve 5, low-noise plate 6, perforated plate 7, noise-absorbing base 8, sound-absorbing material 9, jacket 10, etc.

[0011] In the present invention, the low-noise plate 6 is sequentially welded together with the supporting core sleeve 5 and the perforated plate 7 to form a U-shaped cavity 11 in the middle; The closed cavity is filled with sound-absorbing material 9; the sound-absorbing base 8, the jacket 10 and the perforated plate 7 are provided with several holes 12 near the flange of the sound-absorbing base 8, so that the U-shaped cavity 11 is connected to the atmosphere The valve body 1 is provided with a sealing liner 2 (made of high temperature resistant and corrosion-resistant fluororubber), the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com