Undisturbed stable switching method for industrial enterprise factory electrical system

A plant power system, non-disturbance technology, applied in the direction of electrical components, circuit devices, emergency power supply arrangements, etc., can solve problems such as synchronous motor out of operation, abnormal separation of AC contactors, protection malfunctions, etc., to ensure continuous power supply Continuous operation, simplification of power supply switching operation, and avoiding the effect of operating voltage interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Preferred embodiments of the present invention will be further described below in conjunction with accompanying drawings:

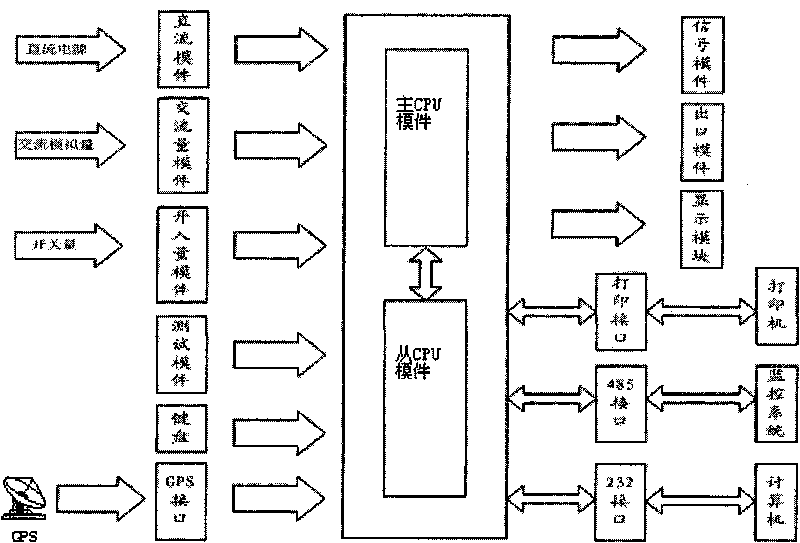

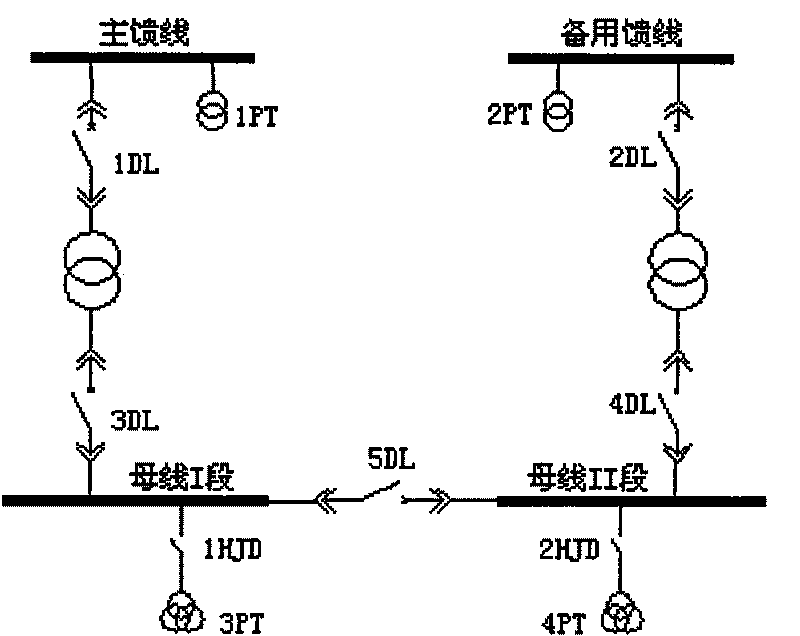

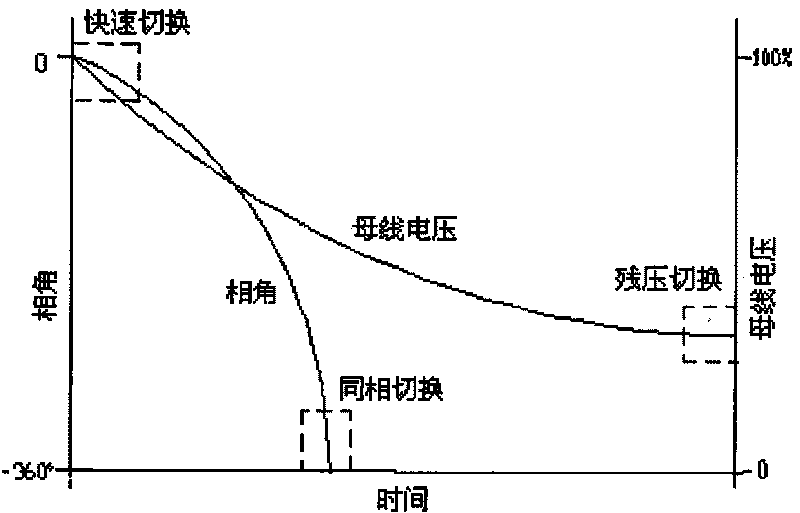

[0044] like figure 1 As shown, the switching method of the embodiment of the present invention is realized by using the non-disturbance stable control device of the dual CPU modules of the master CPU module and the slave CPU module, respectively completing main functions such as measurement, logic and switching, and completing display, Auxiliary functions such as communication and printing, data exchange between master and slave CPU modules. The master and slave CPU modules complete the measurement, calculation and judgment of analog and switch quantities, and the processed signal is isolated and output by optocoupler, and the voltage and current signals from the on-site PT and CT are passed through high-precision current output voltage and current transformers Isolation, filtering and conversion into small signals for use by the main CPU. Variou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com