Surface acoustic wave correlator manufacturing method based on micro electro mechanical technology

A surface acoustic wave and correlator technology, applied in the direction of electrical components, impedance networks, etc., can solve problems affecting the propagation of surface acoustic waves, affecting the performance of correlators, reducing signal strength, etc., to improve processing capabilities, weaken reflections, reduce The effect of small energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

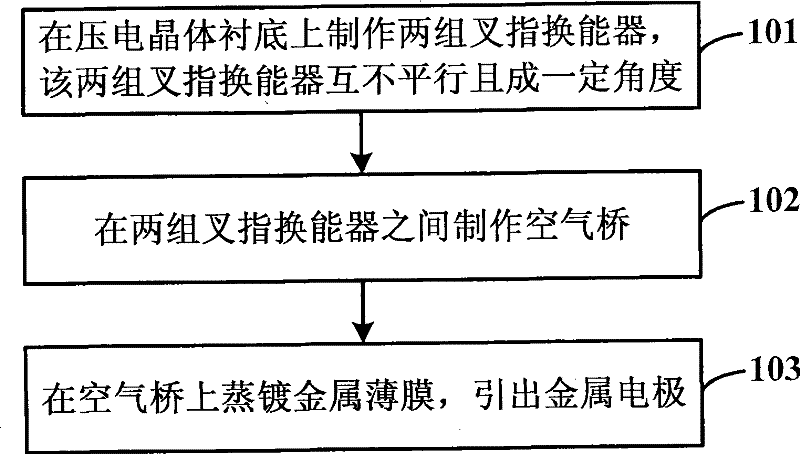

[0030] Such as figure 1 as shown, figure 1 It is a flow chart of a method for manufacturing a surface acoustic wave correlator based on micro-electromechanical technology provided by the present invention, and the method includes:

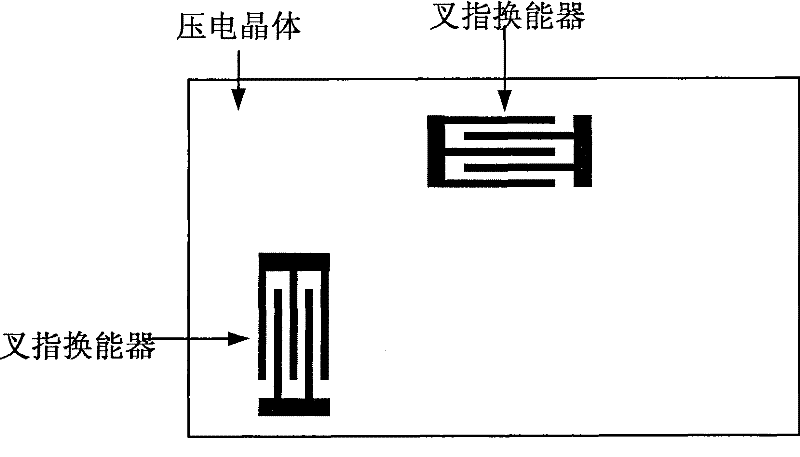

[0031] Step 101: Fabricate two sets of interdigital transducers on a piezoelectric crystal substrate, the two sets of interdigital transducers are not parallel to each other and form a certain angle; the piezoelectric crystal substrate can be a quartz substrate, niobate Lithium substrate or bismuth germanate substrate, etc.

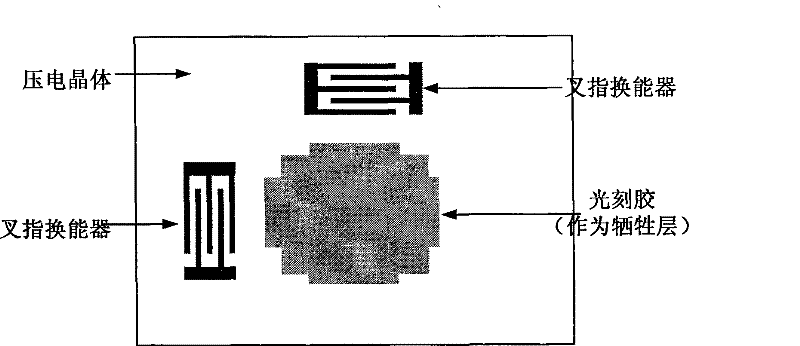

[0032] Step 102: making an air bridge between two sets of IDTs;

[0033] Step 103: Evaporate a metal film on the air bridge, lead out the metal electrodes, and complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com