Flyer structure for laser driving and preparation method thereof

A laser-driven, flyer technology, used in laser welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as low absorption rate, reduce reflection, solve high reflection problems, and improve laser absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

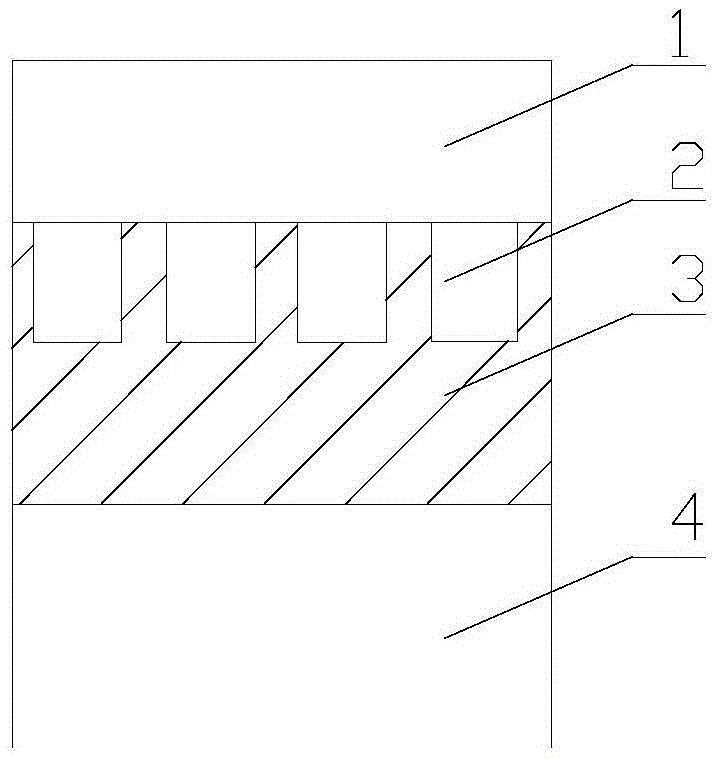

[0027] like figure 1 As shown, according to an embodiment of the present invention, this embodiment discloses a flying sheet structure for laser driving, the structure includes a transparent substrate 1; a nano-aluminum array ablation layer 2 is set on the transparent substrate; An aluminum oxide heat-resistant layer 3 is filled on the aluminum array ablation layer; an aluminum flyer layer 4 is arranged on the aluminum oxide heat-resistant layer. Specifically, the material of the transparent base 1 can be K9 glass, transparent ceramic or transparent crystal. In this embodiment, a layer of metal aluminum is physically deposited on the surface of YAG transparent ceramic as a transparent substrate with a thickness of 1 μm. The metal aluminum is oxidized into porous alumina by anodic oxidation, and then the metal aluminum is electrodeposited in the holes, and the cylindrical nano-aluminum periodic array structure is obtained after the holes are filled. Alumina is filled in the g...

Embodiment 2

[0030] According to another embodiment of the present invention, this embodiment further discloses a method for preparing a laser-driven flyer structure, the method comprising the following steps:

[0031] Step 1. Physically deposit a layer of metal aluminum on the surface of the transparent substrate by means of anodic oxidation or electron beam etching.

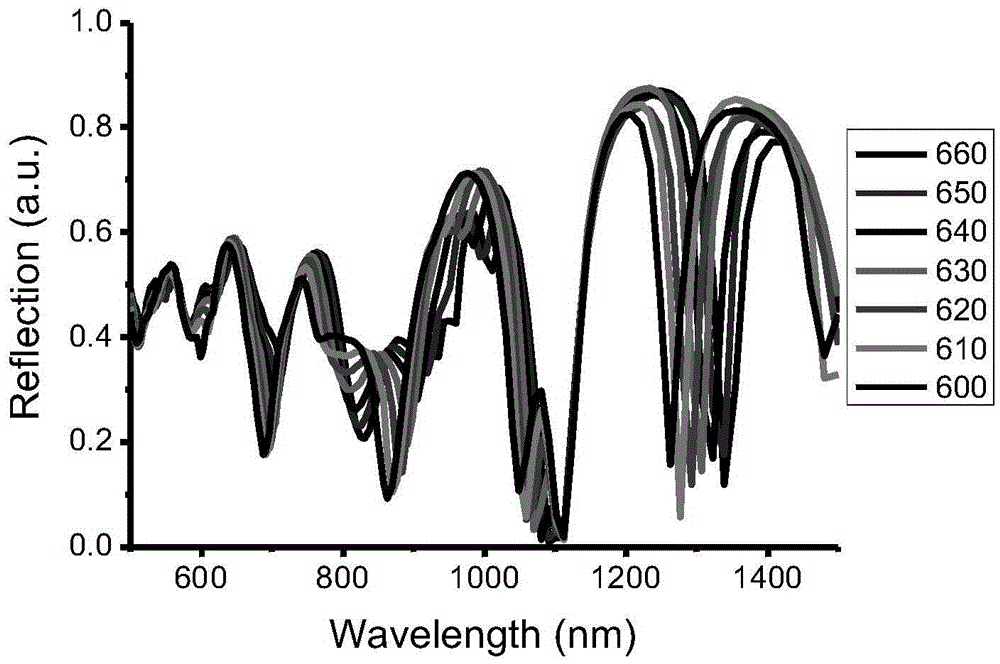

[0032] Step 2. Oxidize metal aluminum into porous alumina, and then electrodeposit metal aluminum in the pores. After the holes are filled, a cylindrical nano-aluminum periodic array structure is obtained; make it produce surface plasmon resonance absorption effect with laser, reduce the metal aluminum to The reflection of laser light improves laser absorption.

[0033] Step 3, magnetron sputtering a layer of aluminum oxide heat-resistant layer on the surface of the cylindrical nano-aluminum periodic array structure.

[0034] Step 4. Deposit a metal aluminum flyer layer on the surface of the alumina heat-resistant layer by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com