Combined super-fine crusher

A technology of fine crushing and reducer, which is applied in the field of rock ore crushing, which can solve the problems of refractory ore going into grinding, and achieve the effects of low wear, high energy efficiency, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

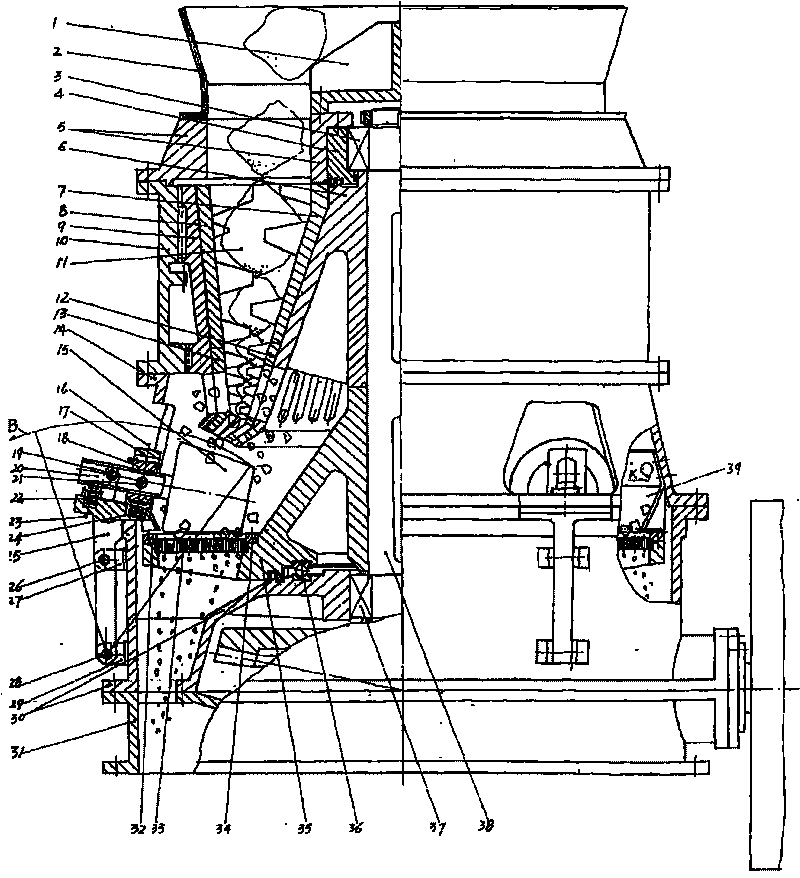

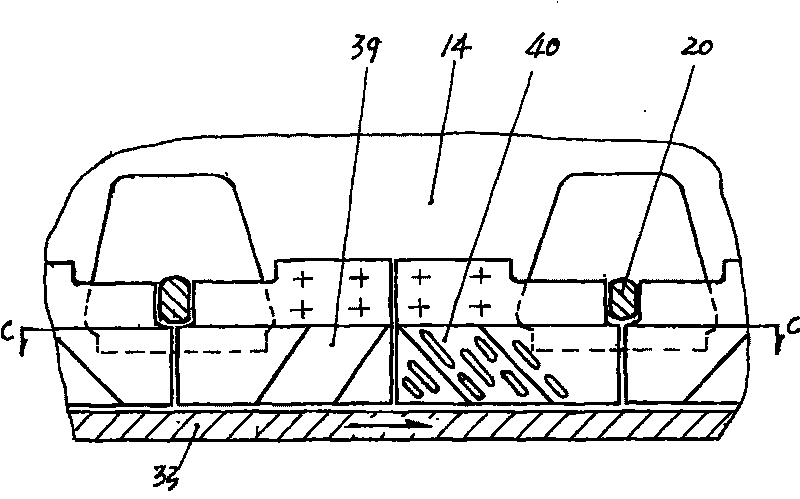

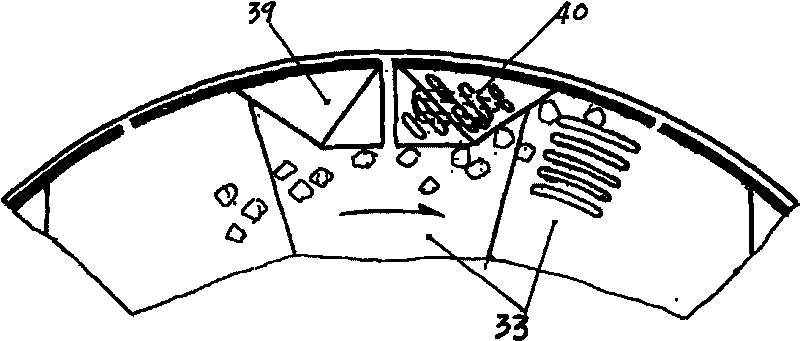

[0023] Such as Figure 1 ~ Figure 3 As shown, the combined ultrafine crusher of the present invention includes a reducer, a vertically arranged main shaft 38, an upper jacket 10, an outer cone sleeve 9, a movable cone sleeve 6 and a disc support sleeve 35, and the upper jacket 10 is located on the outer cone Outside the sleeve 9, the reducer includes a reducer upper box 30 and a reducer lower box 31, the power output end of the reducer is connected to the main shaft 38, and the movable cone sleeve 6 and the roller support sleeve 35 are respectively connected to the main shaft 38 from top to bottom. connection, the outer side of the movable cone sleeve 6 is provided with a movable bevel tooth plate, and the inner side of the outer cone sleeve 9 is provided with an outer bevel tooth plate, and an annular crushing cavity with a wide upper part and a narrower bottom is formed between the movable bevel tooth plate and the outer bevel tooth plate; the movable cone The tooth plate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com